Combo Metal Detector & Check Weigher Weighing Metal Detection Machine

The combo metal detector & check weigher is a powerful solution to ensure both weight accuracy and product safety in one integrated system, detecting both the correct weight and metal contamination of the product in one pass, thereby optimizing production line efficiency while ensuring product safety and quality. The automatic weighing metal detection machine integrates weighing and metal detection functions in one, with a small footprint and compact structure for easy installation and maintenance. For further information about our services, or if you would like one of our professionals to contact you, please do not hesitate to contact us.

Combo metal detector & check weigher photos

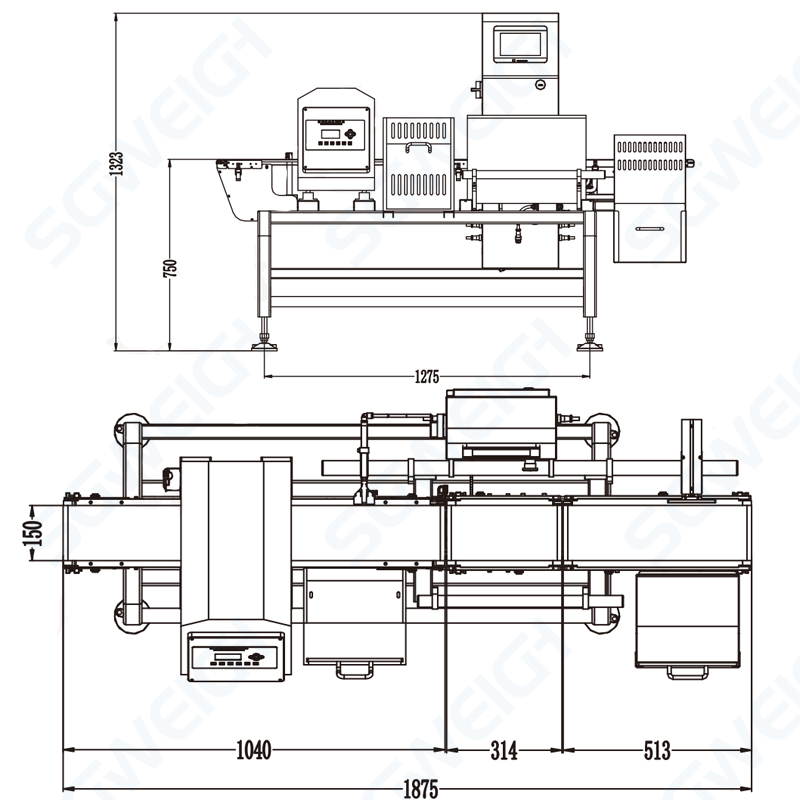

Model SG-JS150

Specifications 4010

Detection of hole width detection 150mm

Inspection hole height 100-200mm

Detection sensitivity

In empty state:(H)100mm ;Fe≥Φ0.8mm,SUS≥Φ1.2mm

(H)120mm ;Fe≥Φ1.0mm,SUS≥Φ1.8mm

(H)150mm ;Fe≥Φ1.2mm,SUS≥Φ2.0mm

(H)200mm ;Fe≥Φ1.5mm,SUS≥Φ2.5mm

Effective hole width detection 150mm

Effective hole detection level 100-200m

Weighing accuracy ±0.1g(Depend on product)

Conveyor height 750mm(±50mm)

Transmission capacity 10kg/times

Transfer direction From left to right

Conveyor belt max speed 25m/min

Material for conveyor belt Food grade PU belt

Protection grade IP65

Display and operation mode LCD flat key input

Deadweight of machine About 240kg

Power supply requirements AC 220V 50HZ

Power About 300w

Overall dimensions About L2267*W589*H1500mm(Design drawing prevail)

How to select suitable combo metal detector & check weigher?

1. Determine the series according to the size, weight range and purpose of the product you need to detect.

2. Determine the appropriate rejection system according to your product

3. Determine the height and width (if any) of your existing assembly line and the space required by our company.

4. Determine the optional functions you need; such as USB storage data, real-time transmission of weight data, alarm, etc.

In order to provide more accurate parameters, solutions and quotations, it is recommended that you contact us to help you complete the selection.

1.Lightweight sructure, less floor space, easy connection with production line, high detection sensitivity and easy operation; it can save production line space to realize more quality control.

2.Advanced technology, applying the latest muti-frequency detection technology, automatic elimination of material effects, automatic balance technology and self-adaptive adjustment technology brings the industry's simplest operation, best environmental adaptability and stability to the equipment.

3.All stainless steel shock absorber structure design and production to ensure long-term stability and service life

4.Can memory 100 different products of the detection parameters, to avoid the detection error caused by artificial differences, and the downtime of the replacement product .

5.Low-power design, flseal design equipment structure ensure the protetive efect of the electronic control partis best, and the protection level reach IP65,can last more than 15 years High-precision digital load cell adopts high-speed digital filter processing and automatic zero tracking.

Combo Metal Detector & Check Weigher Weighing Metal Detection Machine

Combo metal detector & check weighers are widely used in the production and packaging processes of food and beverage, pharmaceuticals, daily chemicals, warehousing and logistics, electronic light industry, packaging and printing, plastic toys, chemicals, agricultural and sideline products and other industries.

Combo Metal Detector & Check Weigher Weighing Metal Detection Machine

1. Packaging materials: International standard export packaging boxes are usually used, which have good wear resistance, shock resistance, and waterproof performance. The material of the box can be hard wooden boxes, plastic boxes, or export specific cardboard boxes.

2. Protective measures: In order to ensure that the weigher is not damaged during transportation, it is necessary to add sufficient filling materials, such as foam, shockproof cotton, etc., into the packaging box.

In order to find the best solution, save costs, provide the best service, and earn more profits for our partners, we look forward to long-term cooperation!

Pre sale.

1. Project design, performance introduction, technical agreement, contract signing, packaging

2. Inquiry and consultation support.

3. Sample testing support.

In terms of sales.

We will provide you with the latest developments in product assembly, packaging, and transportation.

After sales service.

1. We will provide free accessories for non human component damage.

2. Training on how to install the machine, video training on how to use the machine, etc

3. One year warranty and lifelong maintenance

Related Products

Pharmaceutical Box Checkweigher For Medicine

Industrial Metal Detector For Chemical

Automatic Sweetener Multi-Lane Packing Machine

Football Panels Weight Checking Machine With Conveyor

Capsule Tablet Online Sampling Check Weigher

Digital Metal Detector Checkweigher Combo Unit

Aluminum Foil Bags Packaging Checkweigher

Conveyor Belt Metal Detectors For Cosmetic

High Cost-Effective Capsule And Tablet Mini Checkweigher

Metal Detector For Dried Fruit Processing

Hot Labels: combo metal detector & check weigher,weighing metal detection machine,price,supplier,manufacturer