Bottled Pickled Vegetables Checkweigher and Metal Detector Combo Economic Food Weighing Metal Detection Machine

checkweigher and metal detector combo as known as checkweigher and metal detection machine, checkweigher + metal detector, check weigher with metal detection machine, weighing metal detector, weighing metal detection machine, and etc,.

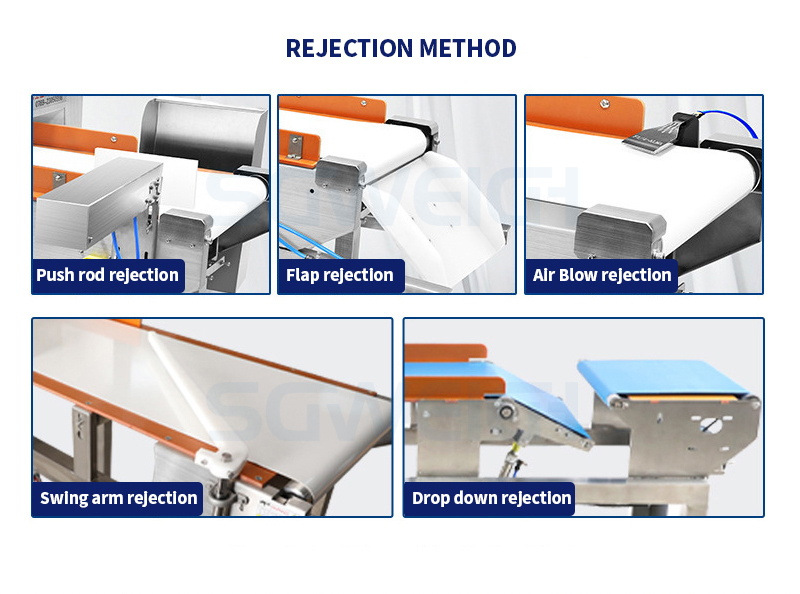

The special design on the structure of the pickled vegetables checkweigher and metal detector combo can effectively avoid external factors such as vibration, noise, and product effects. The food checkweigher and metal detector has high detection sensitivity and good stability. Multiple removal devices are available to choose from to avoid non-conforming products leaving the factory. Any OEM and customer design orders are welcome! If you are interested in our products, please feel free to contact us.

Digital intelligent metal detector for food photos

Detection method: electromagnetic induction/digital weighing sensor

Size: 330 × 150mm

Accuracy: FE0.8mm SUS2.0mm

Selection accuracy: ± 0.5 grams

Weighing range: 5g -900g

Passing height: 110mm

Passing width: 280mm

Packaging length: ≤ 300mm

Display graduation value: 0.1g 0.2g 0.5g 1g

Number of segments selected: 3 segments

Sorting ability: 60 times/minute

Conveyor belt speed: 10-45 meters/minute

Ground clearance: 735mm -800mm

Working temperature: 0-40 ℃

Weight: approximately 160 kilograms

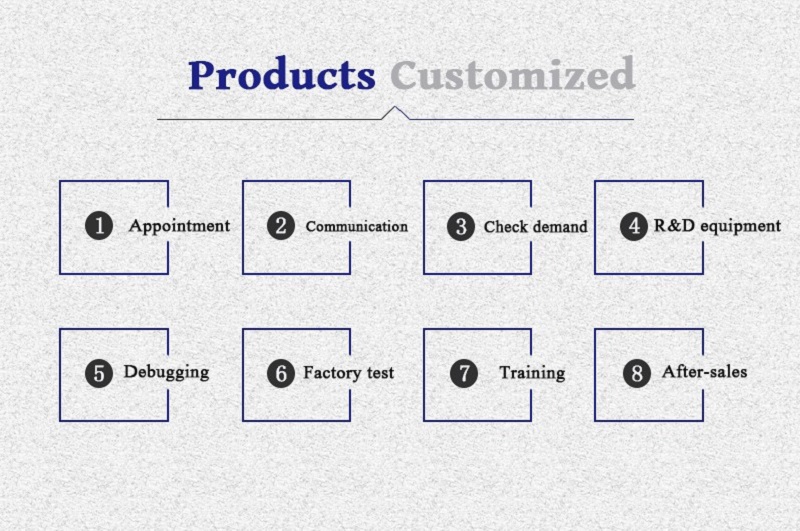

The above parameters are for reference only. We can plan and design multiple sets of checkweigher and metal detector combo solutions based on the products and on-site space provided by the customer.

1. Strong anti-interference ability, such as vibration, noise, etc,

2. High level dustproof and waterproof

3. Able to detect all metals, such as iron, stainless steel, aluminum, copper, and other multifrequency operations

4. Support multi frequency working mode, one machine can maximize the satisfaction of various products with varying moisture content, salt content, sugar content, etc., and accurately set the optimal frequency suitable for the tested product. Phase tracking function

5. Completely solve the problem of phase drift, truly automatic phase correction, and always maintain the optimal detection state of the machine. The optimal detection level is maintained by products that automatically respond to small phase changes. Color touch screen (7-inch TFT LCD)

6. Intuitive and convenient full color touch screen,

7. The instrument is equipped with instructions in various language versions to solve the problems of personnel replacement training and missing instructions. Digital signal processing function

The 11.32-bit microprocessor adopts devices with more precise operation and performance. High performance software filtering technology eliminates the impact of environmental noise on metal detectors, considering convenience and aesthetics in appearance design

8. Modern and emotional design, beautiful and generous data backup, remote debugging and networking functions

9. Implement timely backup of detection data and traceability of detection history.

10. Monitor the real-time operation status of multiple metal detectors, access them through LAN connection, and remotely debug.? Equipped with RS232C and 485 ports, it can achieve linkage and integration with other production equipment. Intelligent automatic setting function

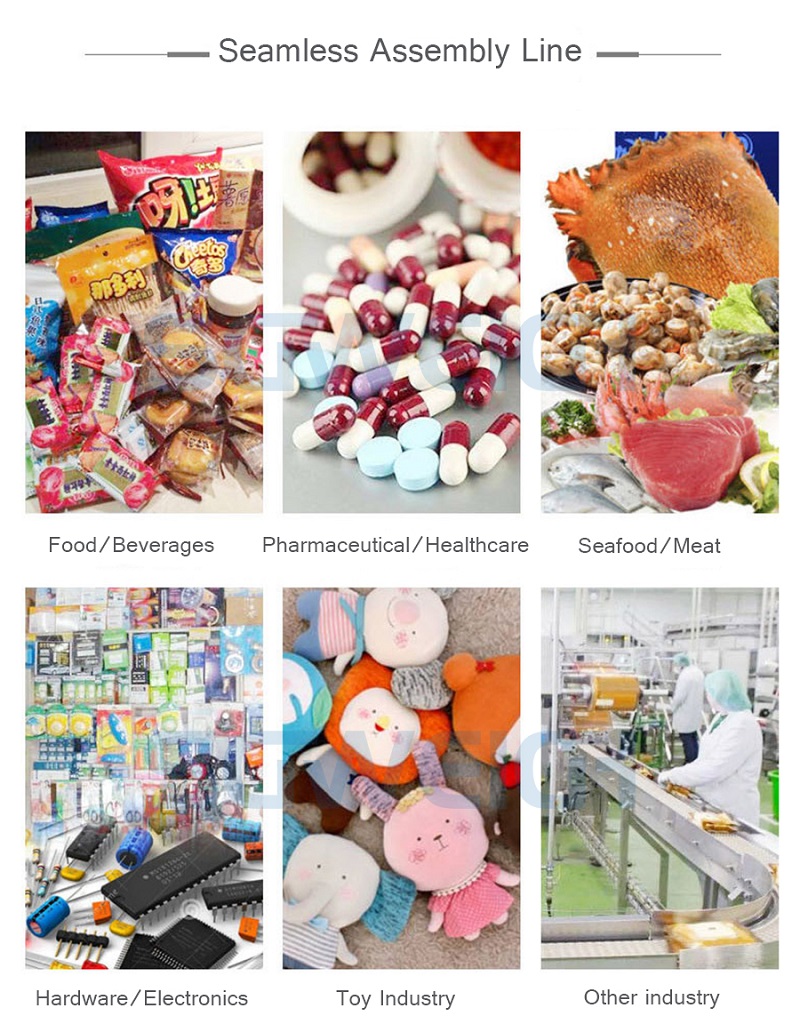

Food checkweigher and metal detector combo is widely used in comprehensive applications such as food, pharmaceuticals, textiles, toys, chemicals, cosmetics, raw materials, etc. Different machine types (conveyor belt type, free fall type, pipeline type, pharmaceutical type, etc.) can meet complete detection requirements.

Shanghai Shigan Industrial Co., Ltd.

1. We produce machines according to the specific requirements of users, such as detecting tunnel dimensions and even special dimensions

2. Same detection sensitivity as European brands, priced at 1/4 to 1/3 of European brands

3. Competitive after-sales service prices, with spare parts charged at cost

4. Query and support fast response, online 24 hours a day, 7 days a week

5. Large production capacity, capable of producing 100 units per month

6. The main products are: a series of assembly line packaging inspection equipment such as vertical packaging machine, prefabricated bag packaging machine, multi-head weigher, linear scale, automatic packaging equipment, multihead weigher, linear scale, check weigher, metal detector, etc.

Packing Detail:

Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.

Delivery Detail :

Shipped in 15 days after payment

Pre sales service

*Inquiry and consultation support.

*Sample testing support.

*Check out our factory.

*Customize

After-sale service

*Train on how to install the machine and how to use it.

*24-hour online service support

*One year warranty

Related Products

100g Nuts Single Head Linear Weigher for Grain Bottling

Food Industry Conveyor Belt Metal Detection Machine

Particle Powder Packaging Machine Multihead Weigher

Box Automatic Checkweigher and Labeling Machine

Efficient Bottled Daily Necessities Rotary Check Weigher

400gm Besan Vertical Granules Packing Machine

Hot Labels: bottled,pickled vegetables,checkweigher and metal detector combo,economic,food,weighing metal detection machine,factory,manuafacturer,supply,price