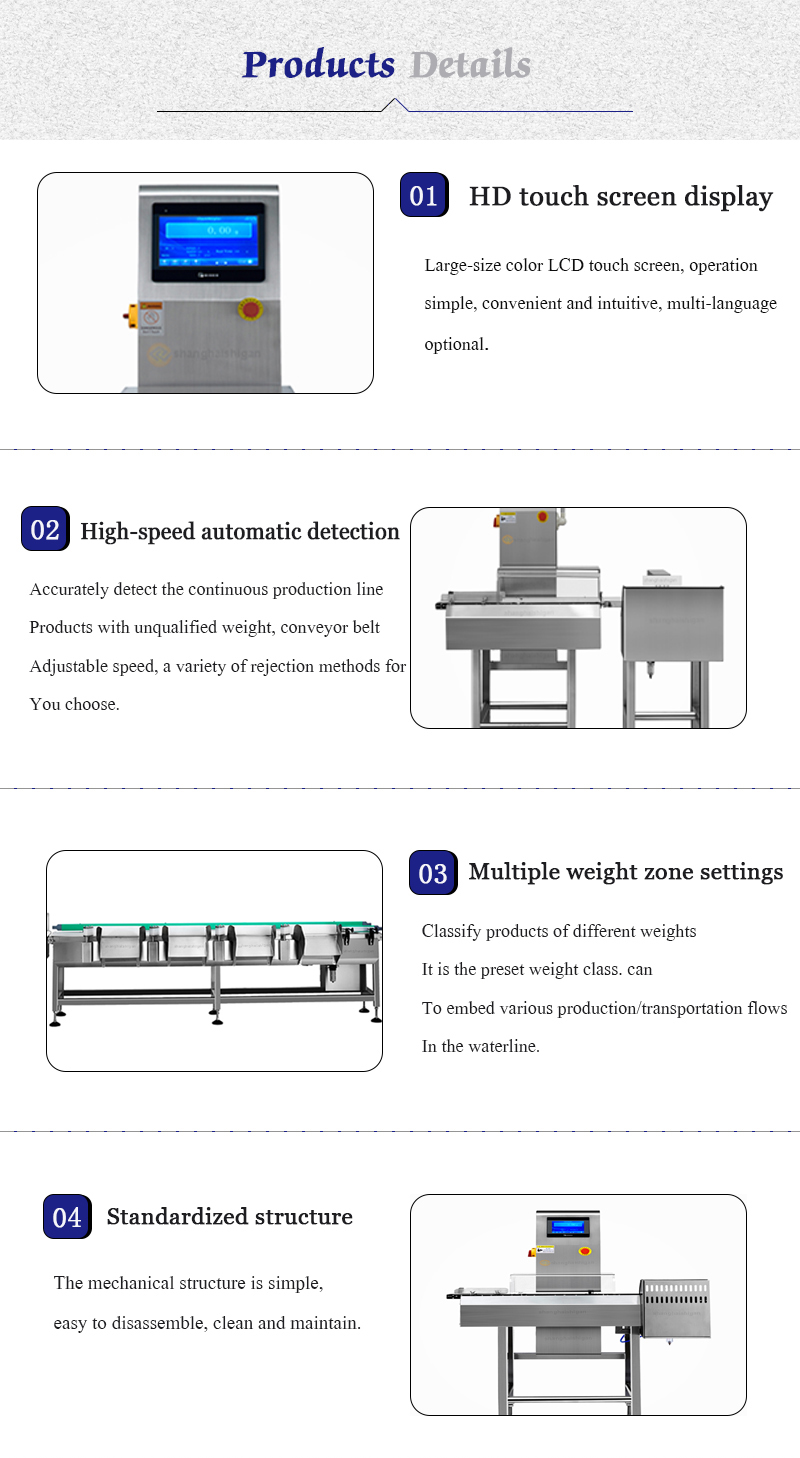

Small Bottle Check Weigher for Pharmaceuticals Automatic Weight Detection

Checkweigher as known as check weigher, check weight machine, check weighing machine, weight checker, weight sorting machine, and etc,.

Small bottle check weigher is an intelligent detection equipment embedded in the streamlined all -weather re -detection. It can help the supplies online calling for various weight abnormalities and identify the corresponding quality abnormal problems. The automatic check weigher for pharmaceuticals has high accuracy, fast speed, wide range of application, high production efficiency, and conveniently embedded in the production line, intelligent product production line. For further information about our services, or if you would like one of our professionals to contact you, please do not hesitate to contact us.

Small bottle check weigher photos

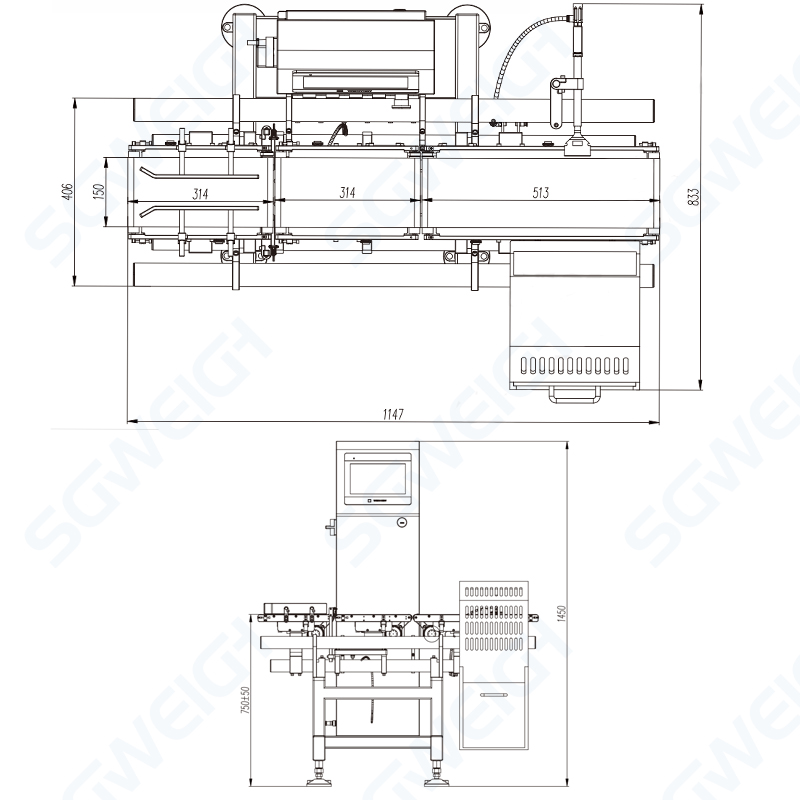

Type SG-150H

Weighing Range 3-500g

Limited of product L: 200 W:150 H: 3-200mm

Accuracy ±0.1g Depends on product

Division Scale 0.1g

Belt Speed 0- 90 m/min

Max Speed 250 pcs/min

Belt Width 150mm

Machine Weight 70kg

Power Supply AC 220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

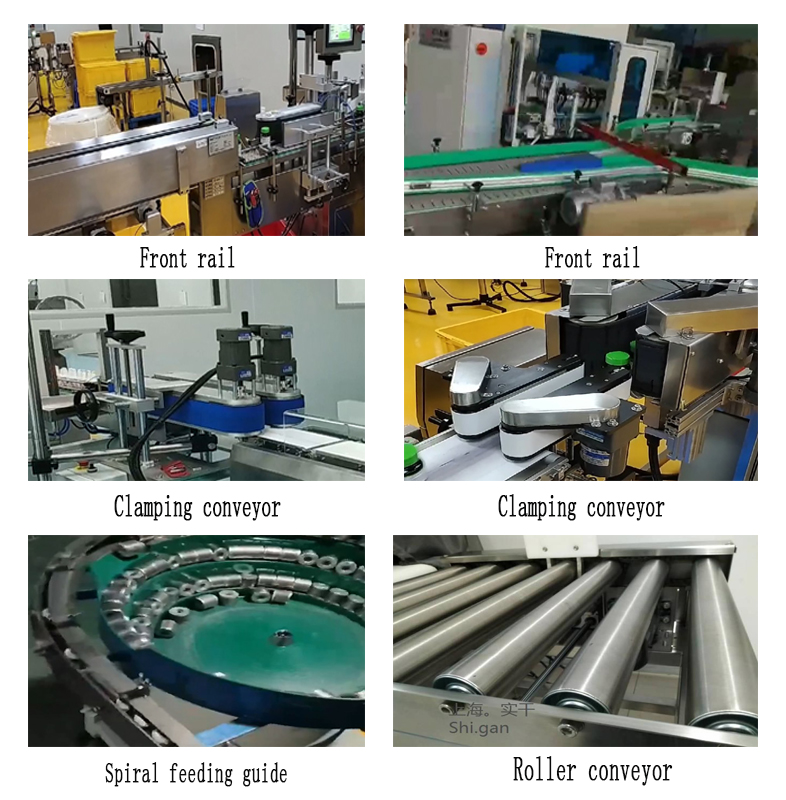

The bottle inspection heavy scale can ensure that the product will not fall under extremely high running state. This series of inspection scale is designed for round bottle or square bottle with a small diameter and high height than the diameter of the bottle body.

Shanghai Shigan provides users with a comprehensive small bottle check weigher application customization services for users in various industries. From the selection, solutions, design, front and back -end connection auxiliary agencies to training services, it aims to meet the user's personalized needs, improve production efficiency, and ensure products to ensure products quality.

1. High precision: Advanced sensor technology is used to achieve high-precision weight measurement, ensuring the accuracy of measurement results.

2. High speed dynamic processing: Adopting a high-speed processing chip, it can quickly respond and handle weight changes, achieving efficient detection.

3. Intelligence: With adaptive adjustment function, it can automatically adjust according to the different characteristics of the item, ensuring the accuracy and reliability of each weighing result.

4. Stability: Stable operation, not easily affected by external environmental interference, ensuring stable equipment operation.

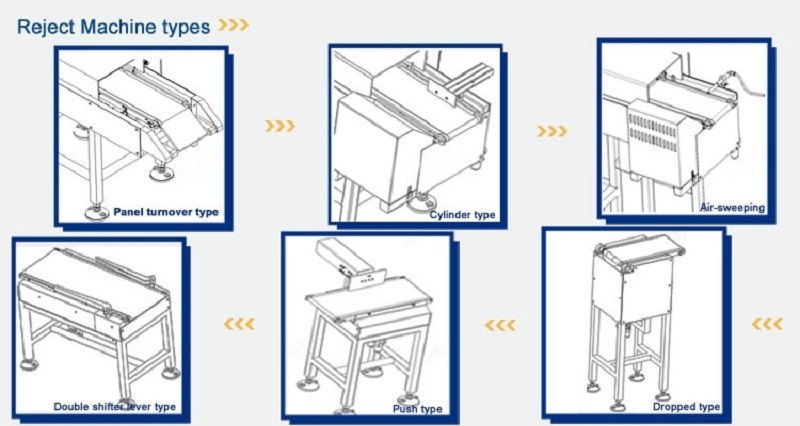

5. Easy to operate: The user-friendly interface makes the operation more intuitive and convenient, making it easy to get started.

6. Diverse functions: capable of detecting overweight and underweight bags, missing bottles, cans, and parts in the entire box, as well as automatic removal of non-conforming products and sound and light alarm functions.

7. Visualization and data management: Modern small bottle check weighers are usually equipped with touch screens or display screens to achieve real-time display and recording of data, facilitating analysis and management.

8. The small bottle check weigher has made significant progress in miniaturization, intelligence, and precision, and has a high cost-effectiveness.

9. The small bottle check weigher also has patented technology.

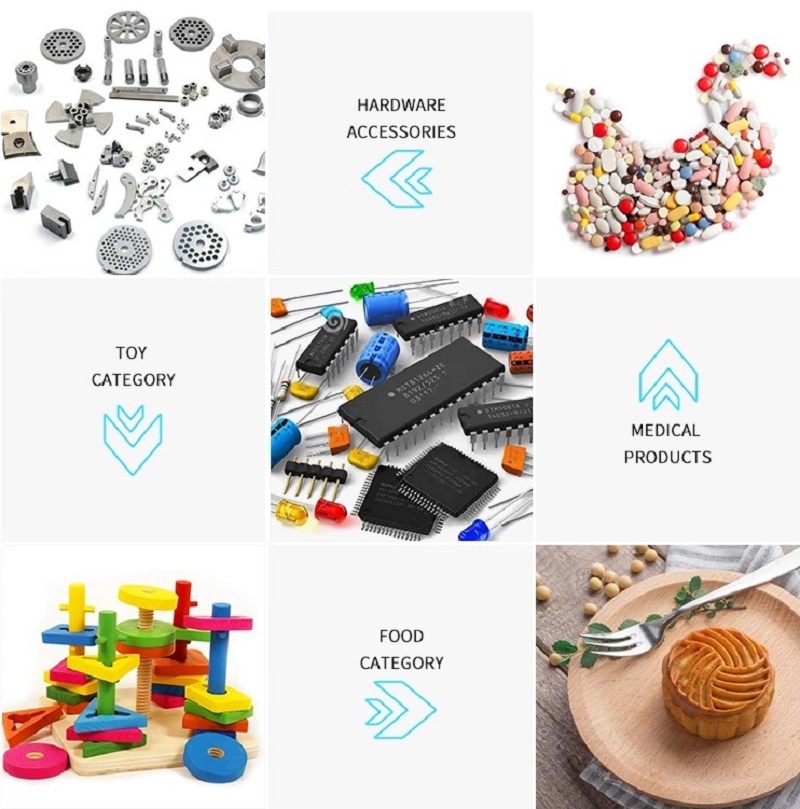

1. Food industry: bagged or canned foods such as rice, candies, beverages, nuts, bread, biscuits, cooking oil, instant noodles, seasonings, puffed foods, snacks, etc.

2. Pharmaceutical industry: whether the tablet drug has fewer or more pills; Is there a shortage or multiple bags of medicine in powder bags; Whether the weight of liquid drugs meets the standard; Drug attachment missing detection (such as instructions, desiccants), etc.

3. Daily chemical industry: weighing detection of the net content of sanitary napkins, paper towels, diapers, cosmetics, wet paper towels, facial mask, shampoo, shower gel, cleaning, washing powder, washing liquid and other household products/detection of missing parts in a whole box/multi-level weight sorting; Detection of missing parts in daily chemical products packaged in boxes, bags, boxes, etc; Daily chemical products have unqualified net content testing, and packaging accessories such as instructions/desiccants/accessories have missed packaging testing.

4. Hardware industry: detection of multiple or missing parts in industrial components, processed parts, and semi-finished products; Small parts missing parts detection: such as toy missing parts detection, screw missing package missing parts detection, TV and set-top box products missing parts detection.

Shanghai Shigan Industrial Co., Ltd. is located in Shanghai, China and has been a professional manufacturer of automatic check weigher, digital metal detector, automatic weighing labeling machine for over 14 years. We have our own factory, and since its establishment, our company has been committed to the new technology field of machines. Now, we have formed a special competitive market based on advanced technology. We have obtained the CE certificate.

Our products not only sell well in the domestic market, but also have good sealing in international markets such as the United States, Africa, the Middle East, and Europe. Our company has always been waiting for the visit of every friend with good quality and excellent service. We sincerely cooperate with each other and work together to create brilliance.

The main products include

Capsule and Tablet Checkweigher

Checkweigher and Labeling Machine Combo

Checkweigher and Metal Detector Combo

1. Packaging materials: International standard export packaging boxes are usually used, which have good wear resistance, shock resistance, and waterproof performance. The material of the box can be hard wooden boxes, plastic boxes, or export specific cardboard boxes.

2. Protective measures: In order to ensure that the weigher is not damaged during transportation, it is necessary to add sufficient filling materials, such as foam, shockproof cotton, etc., into the packaging box.

12 Months Guarantee

★ 12 months free main parts change (Please return the damaged parts by airmail)

★ Overseas engineers available (You only have to pay part of the freight)

Customization

All our machines can be customized , according to your product's features and your workshop environment, or your production line.

After-sales Service Provided

Engineers availbale to provide after-sales service overseas in order to help customers solve technical problems.

Related Products

High Performance Small Box Industrial Check Weigher

Small Aluminum Foil Pouch Tea Metal Detector

Multi-purpose Canned Food Metal Detector

Pharmaceutical Capsule Sample Checkweigher

Large Range Bag Industrial Metal Detector

Automatic Roller Conveying Checkweigher Labeling Machine

Hot Labels: small,bottle check weigher,pharmaceuticals,automatic,weight detection,checkweigher,factory,manuafcturer,price