SG-1X High-precision Balance Grade Check Weigher for Small Pouch

Check weigher as know as checkweigher, check weight machine, weight checker, weight sorting machine, check weighing machine, weighing scale, and etc,.

The automatic check weigher is an automatic device used in automatic packaging production lines to check the weight of products. It can check the weight of products during continuous working processes. In addition, the high-precision check weigher for small pouch has excellent versatility, providing accurate weighing results and automatically rejecting non-conforming products. For further information about our services, or if you would like one of our professionals to contact you, please do not hesitate to contact us.

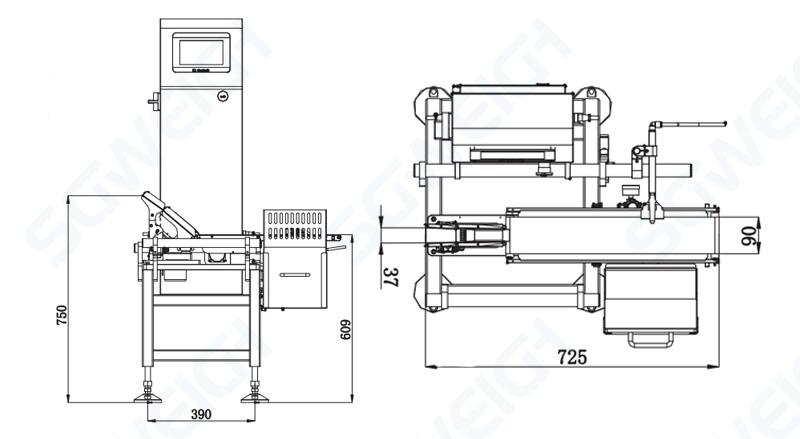

Automatic check weigher for small pouch pictures

Type SG-1X

Weighing Range 1-50g

Limited of product L: 180 W: 40 H: 2-20mm

Accuracy ±0.01g Depends on product

Division Scale 0.01g

Max Speed 70 pcs/min

Belt Width 100mm

Machine Weight 50kg

Power Supply AC 110/220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

1. The displayed model is a standard model and can be customized according to requirements

2. Customize according to customer needs and recommend suitable products to customers.

3. A shelf device that can meet the short-term shutdown of products, allowing the production line to work continuously.

4. Good service. If you have any questions, you can communicate via phone/video.

1. High precision: Adopting advanced sensor technology to achieve high-precision weight measurement and ensure the accuracy of measurement results.

2. High speed dynamic processing: Adopting high-speed processing chips, it can quickly respond to and handle weight changes, achieving efficient detection.

3. Intelligence: With adaptive adjustment function, it can automatically adjust according to the different characteristics of the item, ensuring the accuracy and reliability of each weighing result.

4. Stability: Stable operation, not easily affected by external environmental interference, ensuring stable equipment operation.

5. Simple operation: The user-friendly interface makes the operation more intuitive and convenient, making it easy to get started.

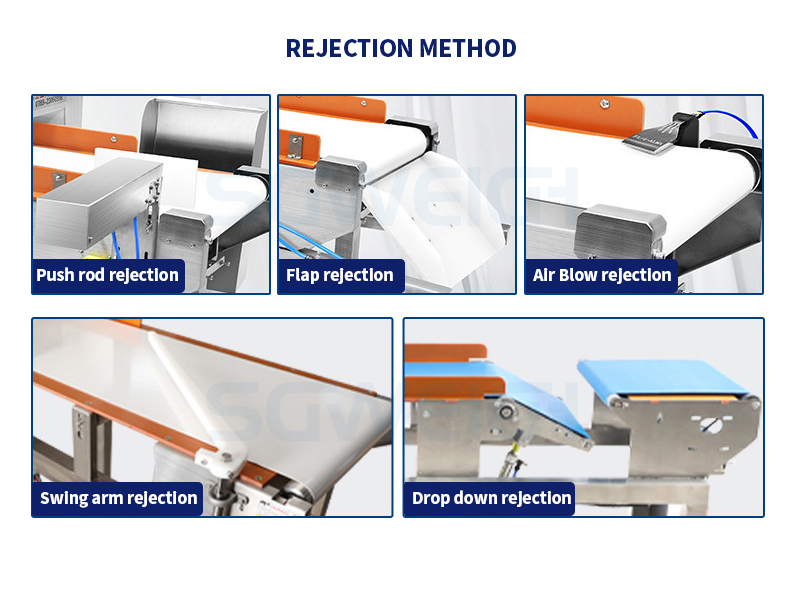

6. Diversified functions: Automatic check weigher can achieve detection of overweight and underweight bags, missing bottles, cans, and parts in the entire box, as well as automatic removal of non-conforming products and sound and light alarm functions.

7. Visualization and data management: Modern weighing scales are usually equipped with touch screens or display screens to achieve real-time display and recording of data, facilitating analysis and management.

8. The automatic check weigher has made significant progress in miniaturization, intelligence, and precision, and has a high cost-effectiveness.

9. The automatic check weigher also has patented technology.

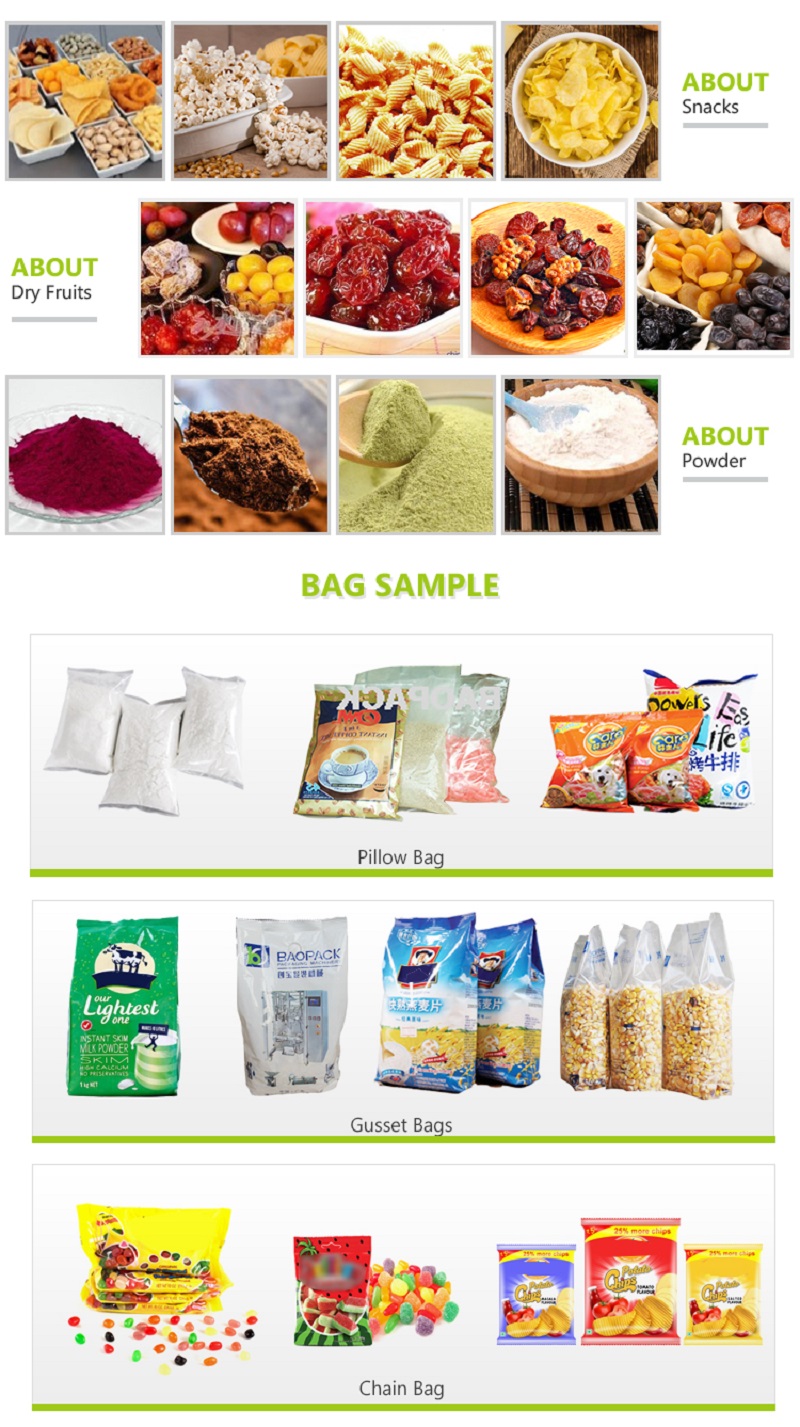

Automatic check weighers have widely applicable: Suitable for industries such as food, pharmaceuticals, cosmetics, toys, plastics, electronic hardware accessories, logistics, light industry, grain, fertilizers, etc., to meet various weight testing needs.

Shanghai Shigan Industrial Co,.Ltd is a professional company engaged in the research and development, production, sales, and service of weighing equipment. Established in 2010, the company is located in Shanghai, China. The main products include automatic check weigher, digital metal detector, food metal detection machine, automatic weighing labeling machine, etc. The company is committed to providing reliable and efficient integrated solutions for various industries. Guided by customer needs, the company continuously innovates and provides customers with high-performance and high-precision weighing equipment. In the future, Shanghai Shigan Company will continue to work hard to improve its own strength, provide users with higher quality products and services, assist enterprise development, and create a better future together.

1. Packaging materials: International standard export packaging boxes are usually used, which have good wear resistance, shock resistance, and waterproof performance. The box material can be hard wooden boxes, plastic boxes, or export specific cardboard boxes.

2. Protective measures: In order to ensure that the weigher is not damaged during transportation, it is necessary to add sufficient filling materials, such as foam, shockproof cotton, etc., into the packaging box.

3. Identification and Marking

1. Customer consultation and technical support: Provide customers with consulting services related to product use, repair, and maintenance, and answer questions they encounter during operation and use.

2. Technical training: Provide training on product operation, maintenance, and repair to meet customer needs, ensuring that customers can use and maintain products correctly.

3. Accessories supply: Provide original accessories to ensure the quality and performance of the accessories and meet the needs of users.

5. One year warranty and lifelong maintenance

6. After sales service tracking: Track and provide feedback on the after-sales service process, timely understand customer needs and opinions, and continuously improve service quality.

Related Products

High Precision Can Multi-level Weight Sorting Machine

Aluminum Foil Food Checkweigher and Metal Detector Combo

50kg Large Volume Industrial Dynamic Checkweigher

Small Sachet Light Industry Mini Checkweigher

Liquid Meat Sauce Digital Metal Detector for Food Industry

Cat Strip Snacks High-efficiency Multi-lane Checkweigher

Hot Labels: high-precision,balance grade,check weigher,small,pouch,automatic check weigher,manufacturer,supplier,factory,price