SG-600 Large Weight Box Food Inspection Checkweigher Conveyor System

Automatic check weigher also called checkweigher, check weight machine, check weighing machine, weight checker, weight sorting machine, weighing scale, and etc,.

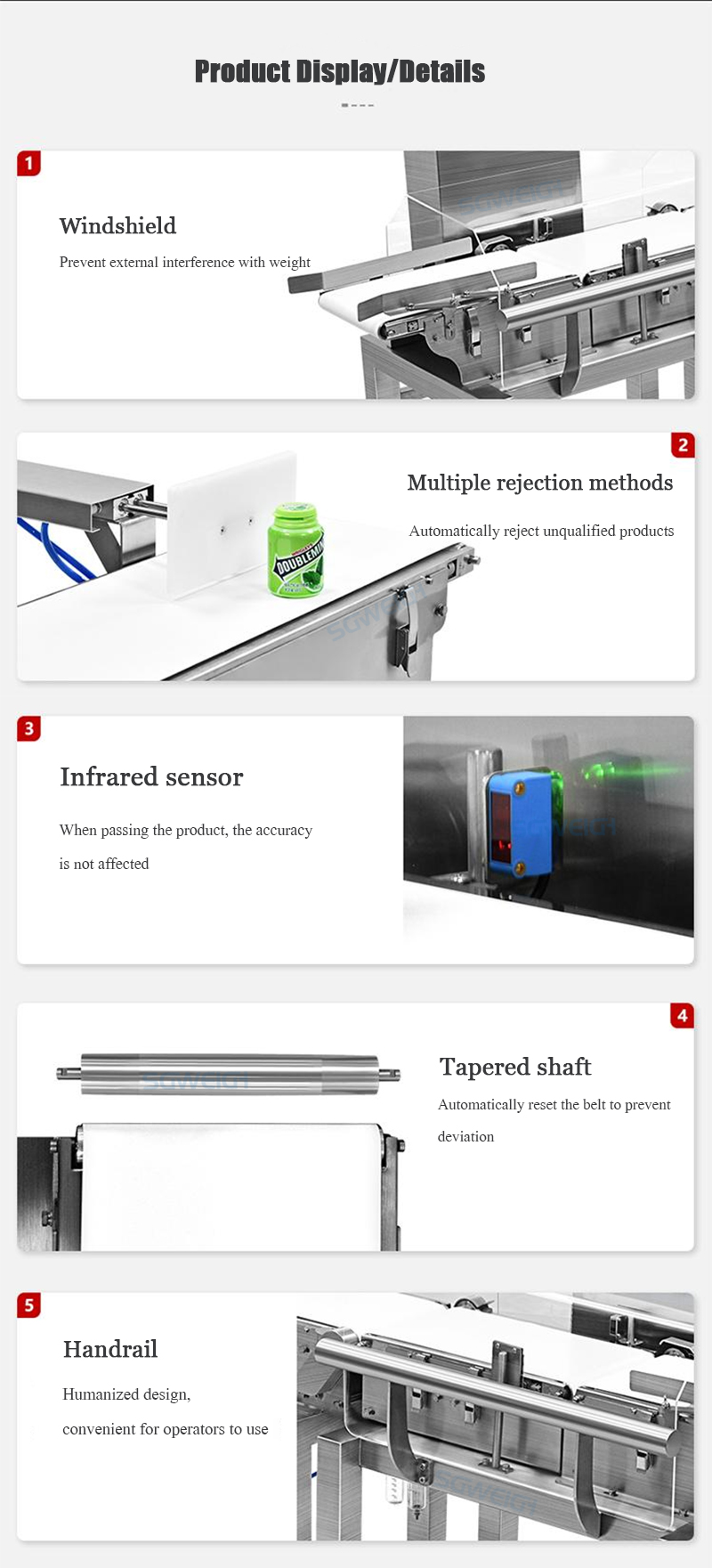

The food inspection checkweigher adopts a continuous dynamic automatic weighing method to detect the weight of items, equipped with an automatic removal mechanism, thereby achieving high-speed and high-precision weight detection and sorting on the assembly line. The unique mechanical structure and operation interface of the checkweigher convyor system design make it very convenient for users to operate and manage data statistics. Our product specifications and sizes are rich, various styles, welcome to contact us for quotation information.

Food inspection checkweigher Pictures

Strong practicality: 7/10 inch high color, high-resolution human-machine interface, easy to operate and user-friendly. Multiple product preset functions, one click to replace product parameters.

High stability: independently developed weighing recognition algorithm, automatic dynamic zero point tracking and anti vibration algorithm, faster and more stable weighing data recognition. Equipped with power outage memory function, it prevents the loss of weighing data in case of sudden power outages, trips, and other situations in the factory.

Convenient docking: With the function of storing and exporting counterweight data, it can store multiple product weighing information and export Excel spreadsheet data from a USB drive; It can be integrated with EMS, WMS and other systems, with product information traceability, remote control of equipment start and stop, and multiple data verification modes to ensure no data leakage.

Rigorous design: modular structure, simple and convenient disassembly and assembly, easy maintenance, and easy cleaning.

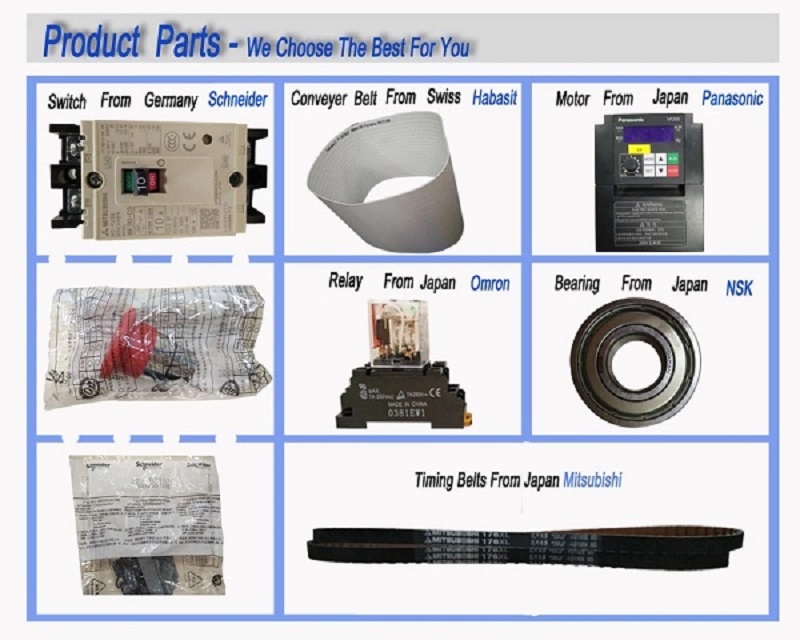

High cost-effectiveness: Different casing materials, sensors, and other standard components can be customized according to the actual needs of customers. Industry applications:

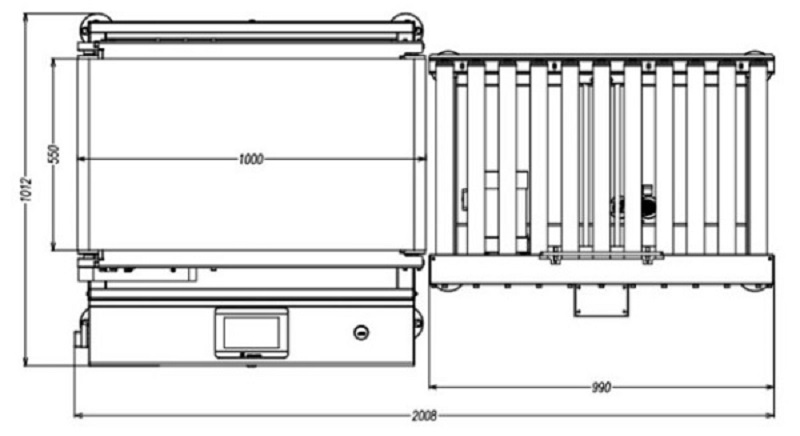

Type SG-600

Weighing Range 0.05-50Kg

Limited of product L: 800 W:550 H: 3-400mm

Accuracy ±20g Depends on product

Division Scale 1g

Belt Speed 0- 40 m/min

Max Speed 30 pcs/min

Belt Width 600mm

Machine Weight 80kg+50kg

Power Supply AC 110/220V ±10% 50HZ

Power 500W

Main Material SU304 stainless steel

1. The speed and accuracy of weight inspection vary depending on the actual product being tested.

2. The standard model is only for selection reference, and specific parameter requirements are customized according to the actual needs of users.

3. Selection: Pay attention to the direction of movement of the product on the belt. If the product is transparent or semi transparent, please inform our company.

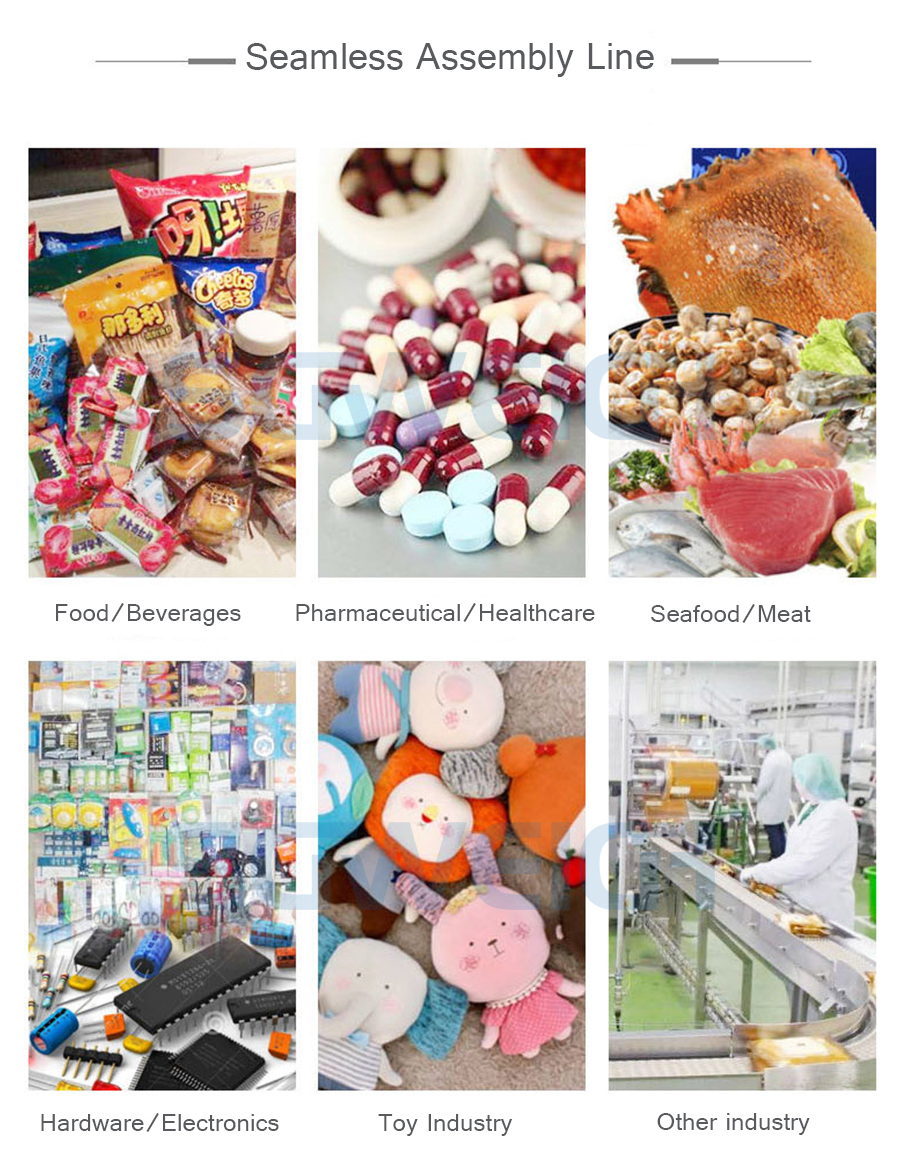

Food inspection checkweighers are widely used in the production and packaging processes of industries such as food and beverage, pharmaceuticals, daily chemicals, warehousing and logistics, electronic light industry, packaging and printing, automotive hardware, plastic toys, chemicals, and agricultural and sideline products.

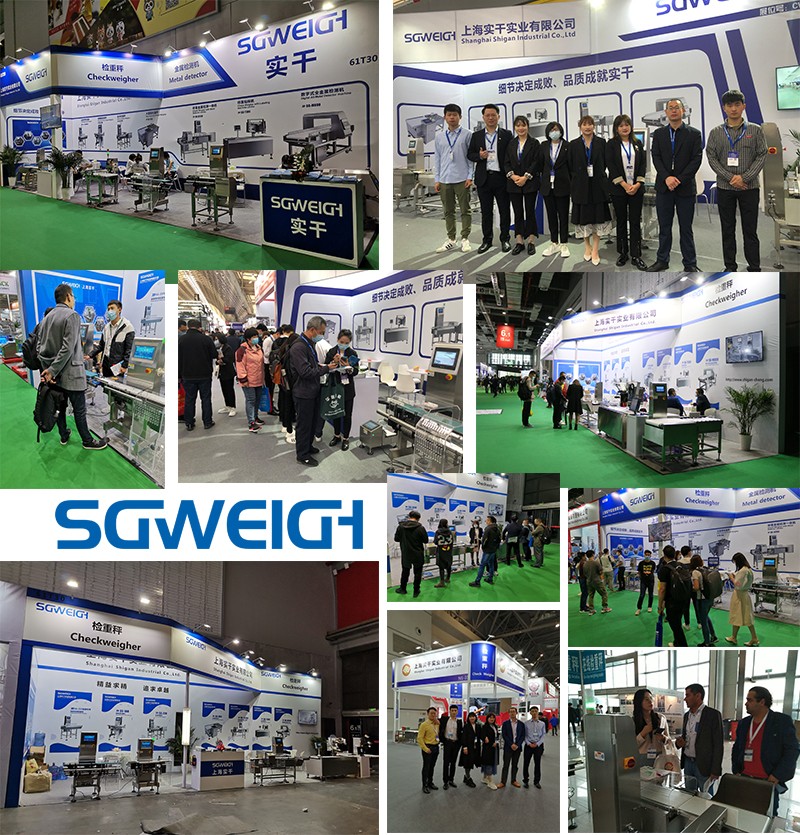

Our company introduction

1. Established in 2010.

2. High tech enterprises in Shanghai.

3. We have over 14 years of experience in the field of checkweigher machinery and have our own factory, which can provide you with the most suitable projects for your needs.

4. 6-8 international machinery exhibitions every year.

5. Supply OEM/ODM manufacturing.

6. Multiple engineers ensure quality/service.

7. As a manufacturer and trader, we have good quality and price control over our products.

8. The product is exported to over 40 countries, including the United States, Canada, and Mexico; Australia, New Zealand; Saudi Arabia, Italy, Spain; France, Poland, Israel, Russia, South Korea; Thailand, Indonesia, Malaysia, Philippines, etc.

9.Our main products

Capsule and Tablet Checkweigher

Checkweigher and Labeling Machine Combo

Checkweigher and Metal Detector Combo

1> Attach safety labels, tighten screws, clean, lubricate, and prevent rust;

2> Disassemble into packaging pieces;

3> Wrap tightly with plastic film;

4> Fixed in plywood box

5> Forklift entering container

Suitable for long-distance land and sea transportation, for safe loading and unloading to the destination, we recommend choosing full container transportation.

1. Equipment installation and debugging: The company provides detailed operation manuals and free operation training to ensure that customers can proficiently use the equipment.

2. Technical support: The company provides 24/7 technical support to solve problems encountered by customers during use.

3. Accessories supply: The company provides original accessories to ensure the quality and stability of the accessories.

4. Quality assurance: The company is responsible for the products sold, ensuring that the quality and performance of the equipment meet industry standards.

5. Warranty policy: One year warranty, lifetime repair, to solve customers' worries.

Related Products

SG-450 Stable High Accuracy Checkweigher with Wide Range

Small Capsule & Tablet Sample Checkweigher

Aluminum Foil Packaging Can Metal Detection Machine

Mini Real-time Display Automatic Check Weigher

Seafood Multi-stage Weight Sorting Machine

Industrial Check Weigher Roller Checkweigher Sorting

Hot Labels: food,assembly line,small,pouch,bag,check weigher,check weighing scale,high speed,conveyor,belt,weight checker,price,supply,factory,manufacturer