Industrial High-precision Weighing Checkweigher High Speed Check Weight Machine

The industrial high-precision weighing checkweigher is a high-precision, economical and practical checkweigher developed by our company, with excellent dynamic checkweighing performance. This high speed check weight machine adopts a high-speed dynamic weighing algorithm to detect whether the single weight is consistent with the target weight, and to remove overweight and underweight products, which can effectively control the quality of the product. The modular design makes the operation and daily maintenance of this series very simple, and it is also easier to meet the requirements of different users. You are welcome to contact us at any time for further information.

Industrial high-precision weighing checkweigher photos

Type SG-220U

Weighing Range 5-1500g

Limited of product L: 300 W:220 H: 3-200mm

Accuracy ±0.2g Depends on product

Division Scale 0.1g

Belt Speed 0- 60 m/min

Max Speed 100 pcs/min

Belt Width 220mm

Machine Weight 65kg

Power Supply AC-220V 50HZ

Power 200W

Main Material SU304 stainless steel

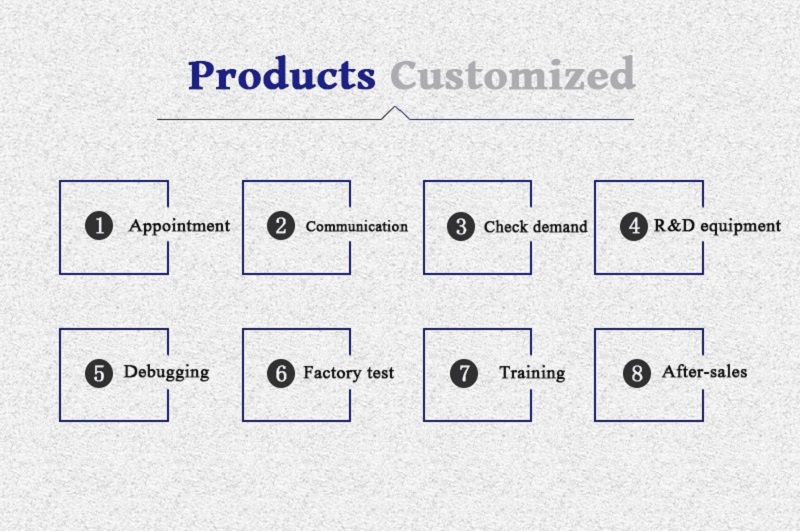

This configuration can also be customized according to customer requirements.

Customized items are as follows:

1. Customized countertops.

2. Customized height.

3. Customized materials.

4. The meter and roller can be wirelessly connected.

5. The meter can have its own USB storage function.

6. The meter can send weight data via Bluetooth.

7. The meter can select the automatic quantitative control output function.

8. External printer function.

9. Built-in upper and lower limit alarm light function.

10. External scanner function.

1. Long-term use, guaranteed accuracy, no need for daily calibration

2. Automatic dynamic zero-point tracking technology

3. Built-in hinge design, no safety blind spots, quick installation and removal of belts, easy cleaning and maintenance

4. Professional human-machine interface design

5. Simple user parameter settings, automatic parameter adjustment, just enter product parameters and weighing requirements to complete parameter settings

6. Accurate and efficient rejection mechanism

7. Humanized function, product database can store 1,000 products

8. Password protection function ensures that unauthorized personnel cannot change data

9. With data statistics function, support data export, USB and Ethernet interface

1. Food industry: rice, candy, beverages, nuts, bread, biscuits, cooking oil, instant noodles, seasonings, puffed food, snack food and other bagged or canned foods.

2. Pharmaceutical industry: whether tablet drugs have fewer or more tablets; whether powder bagged drugs have missing bags or more bags; whether the weight of liquid drugs meets the standard; drug accessory missing detection (such as instructions, desiccant), etc.

3. Daily chemical industry: sanitary napkins, paper towels, diapers, cosmetics, wet wipes, facial masks, shampoo, shower gel, detergent, washing powder, laundry detergent and other daily necessities net content weighing detection / whole box missing parts detection / multi-level weight sorting; boxed / bagged / boxed and other packaged daily chemical products missing parts detection; daily chemical products net content unqualified detection, instructions / desiccant / accessories and other packaging accessories missing detection.

4. Hardware industry: detection of multiple or missing parts of industrial parts, processed parts, and semi-finished products; detection of missing small parts: such as detection of missing parts of toys, detection of missing screws, detection of missing parts of TV sets and set-top boxes, etc.

Industrial High-precision Weighing Checkweigher High Speed Check Weight Machine

Industrial High-precision Weighing Checkweigher High Speed Check Weight Machine

Free export fumigation plywood box with quick connection design, easy to open and reuse;

Internal plastic film packaging can protect goods from salt, wind, or damage;

1. Pre-sales consultation

We will help you customize the appropriate industrial checkweigher solutions according to your requirements and specific circumstances.

2. Installation service

We will dispatch professional technicians to carry out on-site installation and commissioning as needed.

3. Maintenance service

Shigan provides long-term maintenance services, providing any repair parts free of charge during the warranty period, and only charges after the warranty period expires.

4. Staff training

Shigan provides free technical training for our customers to fully master the correct product maintenance technology.

5. Customer service

Shigan designs customized production lines for customers based on specific industrial checkweigher factors such as product output, packaging method and factory area.

Related Products

Large Box Case Carton Checkweigher for Package

Tunnel Metal Detector for Foil Aluminum Pouch

SG-YJ60 Tablet Capsule Metal Detection System for Pharma

Tea Bag Multi-lane Checkweigher

Industrial Box Bag Metal Detector with Rejection System

Glass Bottle Check Weigher for Pharmaceutical Production

Hot Labels:industrial,high-precision weighing,checkweigher,high speed,check weight machine,manufacturer,large range,factory,price