Assembly Line Dynamic 4-lines Multi-lane Checkweigher Packing Line Weight Checker

Product Introduction

The dynamic multi-lane checkweigher is a product weighing and sorting equipment suitable for medium to low speed, high-precision packaging production lines. It can be integrated with various packaging production lines and conveying systems. The assembly line checkweigher is an automatic device used in the automatic packaging production line to check the weight of products. It can check whether the weight of products meets the standard weight we set during continuous operation. Any OEM and customer design orders are welcome! If you are interested in our products, please feel free to contact us.

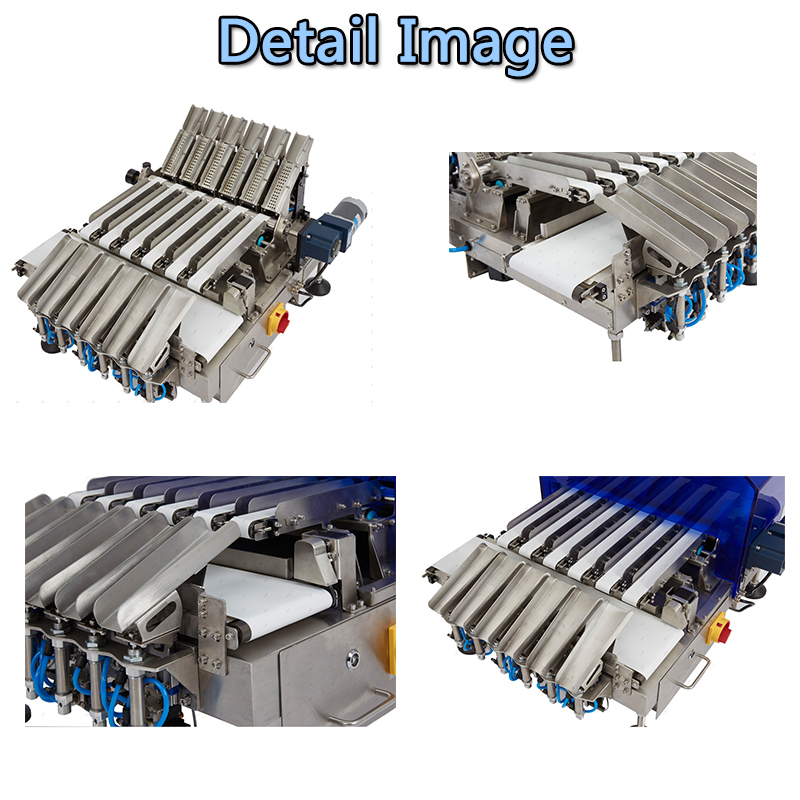

Dynamic multi-lane checkweigher pictures

Product Details

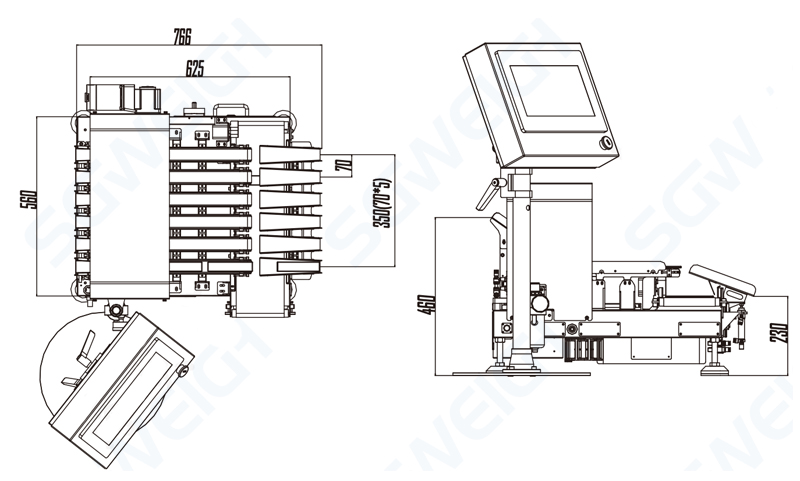

Technical Parameter

Weighing range 1-30g

Minimum scale 0.01g

Maximum sorting speed of 50 pieces/minute (one channel)

Conveying speed 20-100m/min

Operation mode: Touch based operation

The conveying direction can be arranged according to the actual situation on site

Removal method: lifting removal

Belt height above ground 450 ± 50mm (customizable according to customer requirements)

Machine structure stainless steel (SUS304)

Power supply 220V 50-60HZ

Power approximately 1000W

Customized Process

The above parameters are for reference only, and our dynamic multi-lane checkweigher supports customization. Provide the following information to our sales personnel, and our team will support you in selecting the correct type of weighing scale:

*Main parameters of the tested product, product size range: length, width, height

*2. Accuracy requirement: ± g.

*3. Speed requirement: pcs/min;

*4. Product weight range:; The maxi and min deviations of the same product.

Main Features

1. Large size color LCD touch screen interface, simple operation and intuitive display.

2. Support customization of multiple languages

3. Equipped with empty bag photoelectric automatic detection, and the conveyor belt speed is adjustable.

4. Three levels of password protection for parameter settings, only operated by management personnel.

5. Product weighing data can be exported through USB.

6. Power outage protection function, with accidental power outage parameters remaining unchanged.

7. The parameters of different products can be set to store 100 types of detection data, making it convenient for users to switch and call.

8. Data statistics function. The total number of products passed over a period of time/the total number of products that are too light/the total number of products that are overweight.

9. The mechanical structure is simple, and the buckle type conveyor belt is convenient for disassembly, cleaning, and maintenance. Complies with GMP and HACCP specifications.

10. Automatic dynamic compensation value and dynamic zero point tracking, including zero point tracking during continuous equipment operation, to ensure the reliability of detection data.

11. The curve/bar chart displays the statistical distribution of sorting (re inspection) results, and the window displays the values of the last 10 re inspection results.

12. Adopting patented technology, the microcontroller system is independently developed, with a unique filtering algorithm that has ultra-high accuracy and reliability. Ensure system stability.

Application Scope

Dynamic multi-lane checkweighers are widely used in industries such as food and beverage, pharmaceuticals, daily chemicals, warehousing and logistics, electronic light industry, packaging and printing, automotive hardware, plastic toys, chemicals, agricultural and sideline products for automatic weighing and weighing on the assembly line.

Company Profile

Shanghai Shigan Industrial Co., Ltd. is a professional enterprise that produces and sells various types of weighing automation equipment. The company integrates research and development, design, production, and sales business, and its products are best-selling throughout the country. The company is located in Shanghai, China and has gained a good reputation through 13 years of experience in mechanical production. We will continue to focus on mechanical production in a rigorous and innovative manner, serving customers around the world. Our main products:

Capsule and Tablet Checkweigher

Checkweigher and Labeling Machine Combo

Checkweigher and Metal Detector Combo

Our Customers

Our Exhibition

Packing & Shipping

1> Stick safety labels, tighten screws, clean, lubricate, and prevent rust;

2> Disassemble into packaging;

3> Wrap tightly with plastic film;

4> Fixed in plywood box

5> Forklift entering container

Suitable for long-distance land and sea transportation, in order to safely load and unload to the destination, we suggest that you choose full container transportation.

After-sale Service

Pre sales service

Before providing suggestions to customers, we will clearly confirm their requirements to ensure that the suggestions we provide meet your requirements. Then we will give you a good quote.

On sale services

After placing an order with our production department, we will follow your order well and inform you of the production status. We will provide you with photos

After-sale service

The warranty period for this machine is one year, calculated from the date the customer receives the machine. During the warranty period, we will replace damaged parts (excluding human damage).

Related Products

High Accuracy Quantitative Industrial Check Weigher

High Precision Capsule Sampling Checkweigher

Strips Multi Lane Checkweigher for Food Powder

Reagent Bottles Rotating Weighing Checkweigher

SG-220U Online Dynamic Box Industrial Checkwiegher

Cosmetic Checkweigher Metal Detector Combo

Hot Labels: assembly line,dynamic checkweigher,multi-lane checkweigher,weight checker,packing line checkweigher,manufacturer,supplier,price