SG-220U Online Dynamic Box Check Weigher Machine Industrial Checkwiegher

Checkweigher also called check weigher, check weight machine, weight checker machine, weight sorting machine, check weighing machine, and etc,.

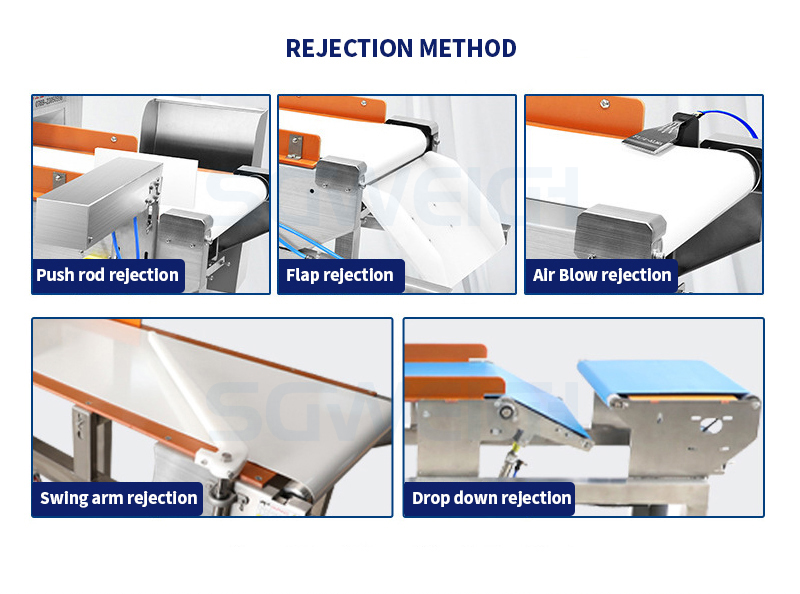

Box check weigher scale is a high-precision and high-efficiency automated weighing equipment, suitable for weight detection and quality control on various production lines. The automated operating system can automatically complete weighing, detection, and recording. The operation of the dynamic industrial checkwiegher is stable and simple, with multiple rejection systems to choose from. It integrates with upstream and downstream equipment to form a complete packaging line. Our products have a wide range of specifications, sizes, and styles, providing various customized solutions. Welcome to contact us.

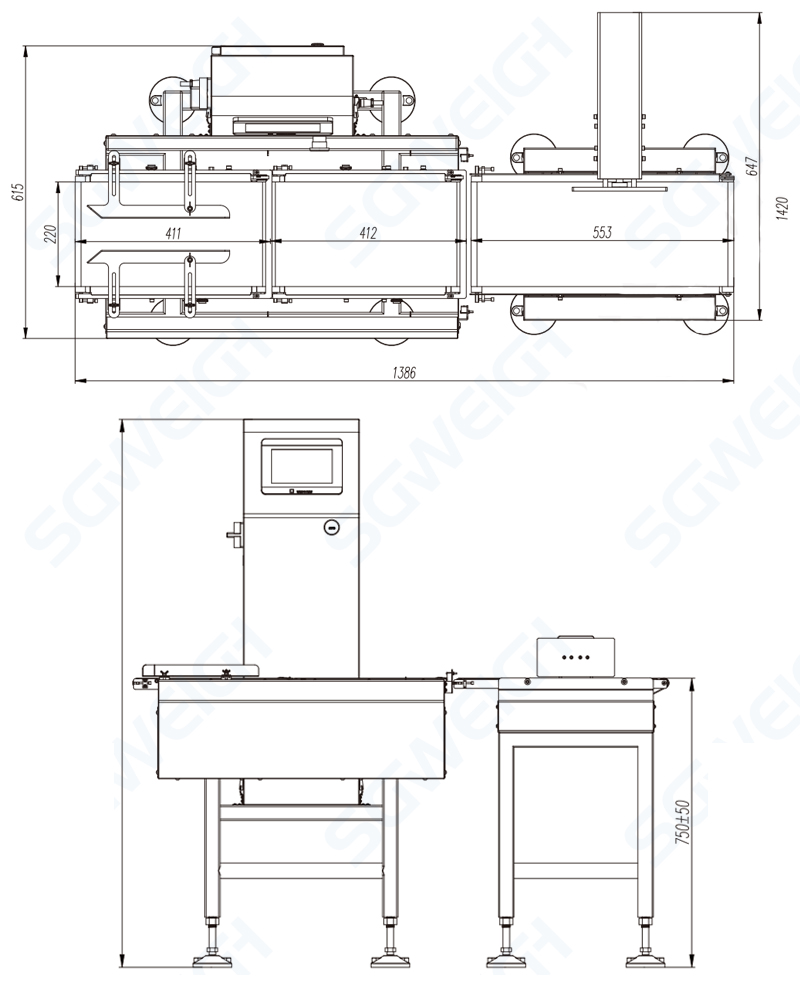

Box check weigher scale pictures

Type SG-220U

Weighing Range 5-1500g

Limited of product L: 300 W:220 H: 3-200mm

Accuracy ±0.2g Depends on product

Division Scale 0.1g

Belt Speed 0- 60 m/min

Max Speed 100 pcs/min

Belt Width 220mm

Machine Weight 65kg

Power Supply AC-220V 50HZ

Power 200W

Main Material SU304 stainless steel

1. The properties of the tested product are also different from the usage environment, resulting in slight differences in actual detection speed and accuracy

2. The displayed machine is of standard specifications, and other sizes and special requirements can be customized

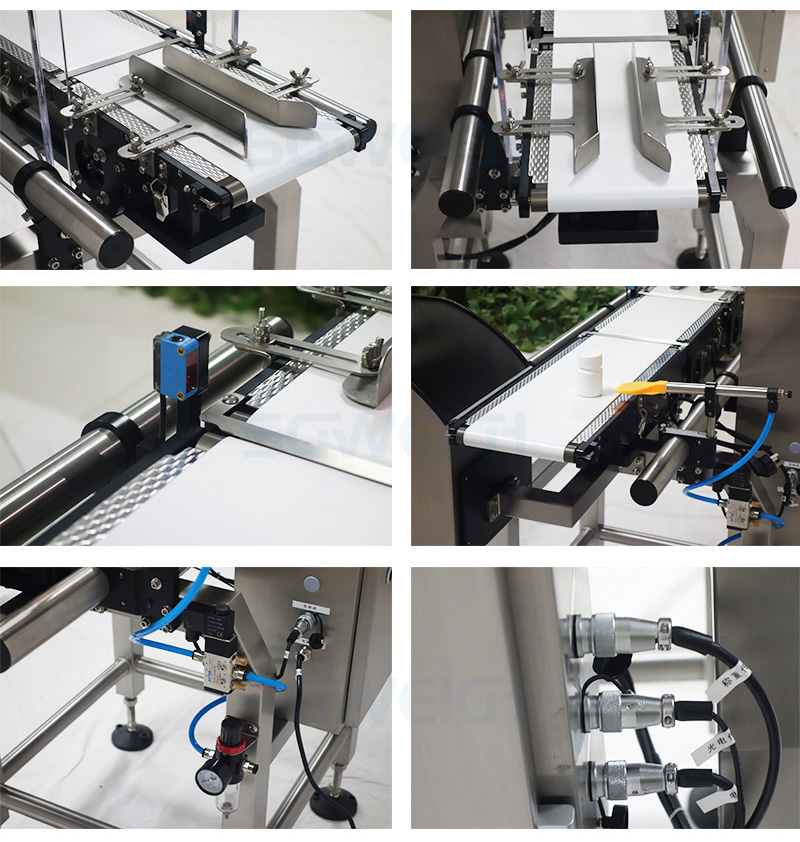

1. 10 inch color touch display screen; Like a smartphone, the operation is simple.

2. Quick belt replacement system; Adopting a buckle design, cleaning the belt is very easy.

3. Up to 10 shortcut menus, seamless integration for product switching, achieving non-stop product switching.

4. Unqualified product query printing

5. Provide feedback signals on production trends, adjust the packaging accuracy of upstream packaging machines, improve user satisfaction, and reduce costs.

6. All core components are made of imported accessories to ensure the stability of equipment operation

7. Independent processing plants enable lower costs and the most affordable prices for equipment of the same grade.

-Leisure and leisure food: various packaging such as potato chips, cookies, jelly, sweets, tea bags, instant noodles, etc.

-Agricultural products: rice bags, dried fruit net bags, grains, frozen products

-Daily cosmetics: bottled shampoo, makeup bags, filled aerosols

-Hardware industry products: printing, toys, PCB boards, metal parts

-Pharmaceutical industry: bottle pills, small particle sachets, pulse bottles, etc.

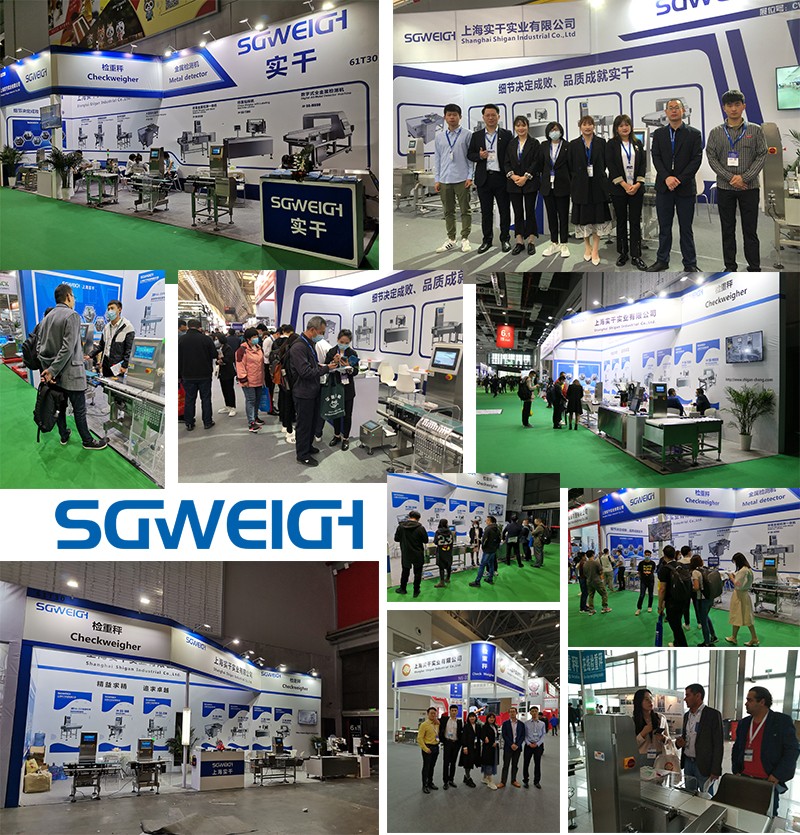

Shanghai Shigan Industrial Co., Ltd. was founded in 2010 and is located in Shanghai. Shanghai Shigan has an independent research and development institution, a complete production and manufacturing system, and a huge marketing service network. It is an international assembly line testing equipment manufacturer that integrates research and development, manufacturing, marketing, and service. At present, all of our company's products have passed CE and EU certification, and have been exported to multiple countries and regions such as Europe, the United States, Singapore, Thailand, etc.

Our products

Capsule and Tablet Checkweigher

Checkweigher and Labeling Machine Combo

Checkweigher and Metal Detector Combo

Packaging

Film pack inside, Wooden case outside

Shipping

1. Upon receipt of payment, delivery date will be in 20-30 working days

2. By Air, by Sea or by Express (DHL, UPS, TNT, EMS, etc.)

1. Service tenet: Shanghai Shigan Industrial Co., Ltd. is committed to providing customers with fast, decisive, accurate, thoughtful, and thorough services to meet their equipment needs.

2. Service objective: The company takes high-quality service quality as the standard, aiming to win the satisfaction and trust of users.

3. Service efficiency: The company promises to provide effective solutions within 24 hours in case of equipment failure, ensuring that customer production progress is not affected.

4. Service principle: The company's product warranty period is twelve months. During the warranty period, for equipment damage caused by quality reasons, the supplier will provide free repair and replacement parts. If the equipment parts are damaged outside the warranty period, the supplier will only charge the cost price. For equipment damage caused by customer human factors, the supplier's repair or parts provision will be calculated at cost.

Related Products

Capsule High-precision Vertical Metal Detection Machine

Large-range Bag Checkweigher With Custom Guide Rail

Medicine Capsule High Precision Metal Detector

Multi-level Weight Sorting Machine for Bagged Bread Food

Pharmaceutical Box Check Weigher Scale

Metal Detector Machine for Food Packaging Facility

Hot Labels: online,dynamic,box,check weigher machine,industrial,checkwiegher,price,supplier,manufacturers,factory