Aluminum Foil Plastic Bag Waffles Metal Detection Machine Food Industry Dynamic Automatic Metal Detector Supply Iran

The food industry digital metal detector has extremely high stability and the ability to eliminate product effects. Dynamic automatic metal detector can automatically analyze the signal characteristics of the product, set the detection parameters of the specified product, simplify the parameter setting process, and automatically store 50 product parameters. Highly intelligent operation, excellent performance, easy to use, and improved production efficiency. Any OEM and customer design orders are welcome! If you are interested in our products, please feel free to contact us.

Food industry digital metal detector photos

1. Phase tracking function, maintaining stable high sensitivity detection capability.

2. Product tracking function, which can automatically adjust and compensate based on changes in product effectiveness.

3. The automatic balance calibration function ensures the service life of the machine.

4. Food industry digital metal detector can automatically inspect products, analyze and record.

5. The product database can store 5100 products.

6. IP65 dustproof and waterproof.

7. The conveyor belt performance meets the US Food Hygiene Standards (FDA) and can be directly used for the inspection of non caked food.

8. Food industry digital metal detector can work stably for a long time and is specially designed for harsh production environments with strong vibration and high interference. Even if the probe is lightly tapped, it will not leak an alarm.

9. Friendly user interface and convenient operation. LCD display.

10. Dual channel detection: one channel detects defects FE, and the other channel detects non-ferrous metals.

11. Food industry digital metal detector can be matched with assembly line operations or automatic control devices.

12. Alarm method: Audible and visual alarm, automatically stopping operation.

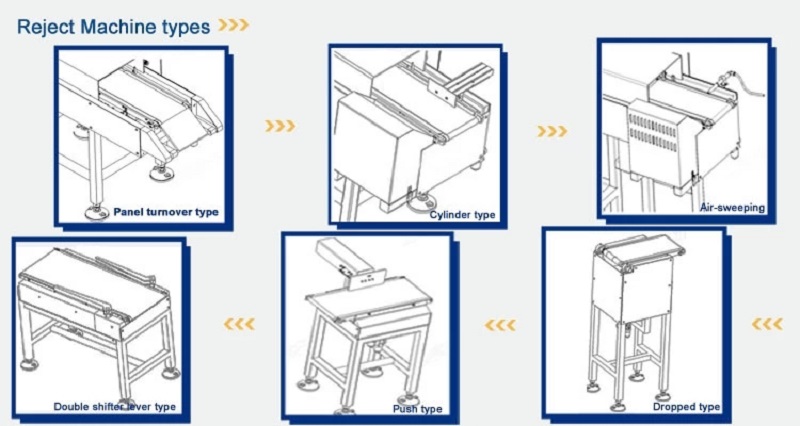

13. Automatic removal equipment can be installed according to customer requirements.

Detection method: magnetic field induction, digital circuit processing

Inductive adjustment: 1-10 levels adjustable

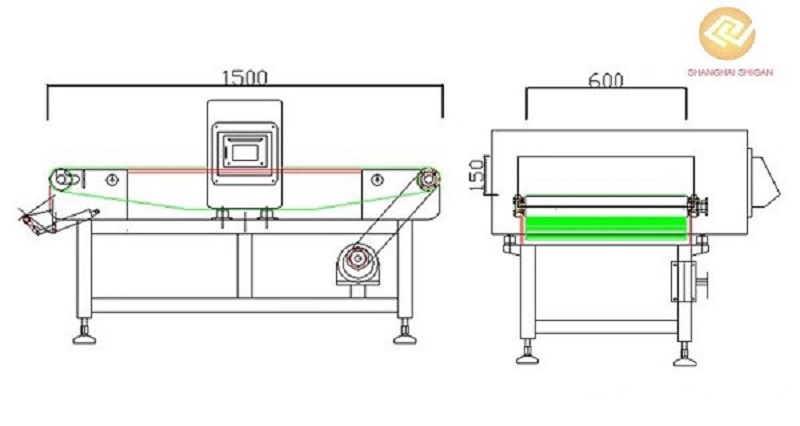

Detection width: 600mm or customized by the customer

Detection height: customized by customers

Alarm method: sound and light alarm, conveyor belt automatically retreats, and eight point detection position display

Power supply: Ac220V 50-60Hz

Power: 60/90W

Body size: approximately 1700 long × 110 wide × High (to be determined)

Net weight: approximately 250KG

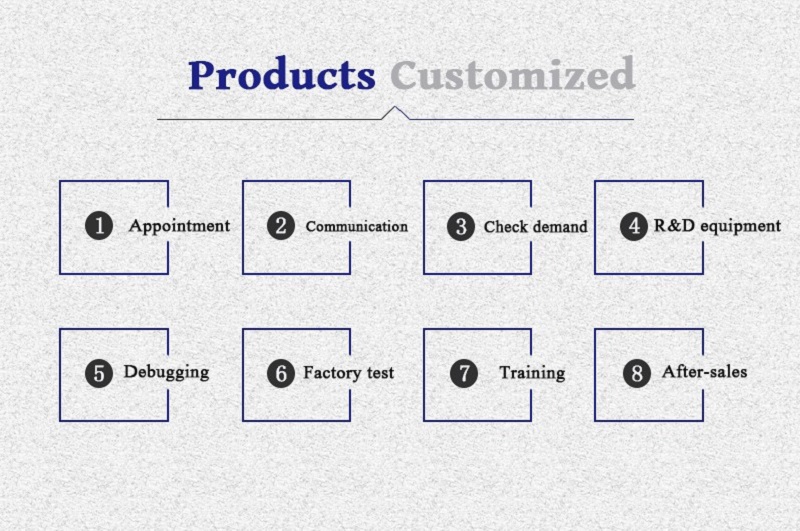

Customized solutions to meet complex needs:

There is no identical production line, let alone a universal dynamic automatic metal detector scheme. Our professional engineers will rigorously evaluate the characteristics, specifications, and environmental factors of the production line, and design the most suitable dynamic automatic metal detector scheme for you to meet the different needs of various complex production lines.

Food industry digital metal detector is suitable for industries such as biscuits, sauces, sausages, dumplings, ham, soup, sugar products, pickled foods, fresh meat, frozen foods, salted foods, fast food, baked goods, and other industries with high detection sensitivity, anti-interference ability, and waterproof requirements. It can be used to detect broken needles, iron wires, lead, copper, aluminum, tin, stainless steel, and other metals mixed or lost in food, raw materials, or products.

Located in Shanghai Songjiang High tech Industrial Park, Shanghai Shigan Industrial Co., Ltd. is committed to product development, manufacturing, sales and service of automatic equipment such as auto packing machines, multihead weighers, check weighers, weighing filling machines and metal detector. We always focus on automation, relying on high-quality, high-performance, and highly flexible products to meet the needs of domestic and foreign customers. Shanghai Shigan has strong technical strength, and our product performance is at the forefront of the industry. Main products: automatic equipment such as weighing scale, multi-stage sorting machine, Metal detector, etcThe main products are: a series of assembly line packaging inspection equipment such as vertical packaging machine, prefabricated bag packaging machine, multi-head weigher, linear scale, automatic packaging equipment, multihead weigher, linear scale, check weigher, metal detector, etc.

The Delivery Date: After receiving the payment, the delivery date will be within 15-30 working days

Packaging: Protective film + wooden case

Logistics: Air, sea or express (DHL, etc.)

The Freight: The cost of transport depends on the destination, mode of transport and the weight of the goods

Pay: T/T, Western Union, paypal

1. Provide a manual.

2. Provide videos of installation, adjustment, setup, and maintenance.

3. Provide remote education and face-to-face online communication.

4. The warranty period for the machine is 1 year, and the warranty period for spare parts is 2 years. During the warranty period, if there is no human damage, we will replace it with a new one for you. The warranty period will be calculated from the date of B/L.PET bottle making

Related Products

Semi-automatic Filling Weighing Machine For Coffee Powders

Automatic Vacuum Packing Machine For Dried Squid Seafood

Loose Material Multi Head Electronic Scale Packing Machine

Stable High-precision Slender Bottle Check Weigher

250g Automatic Packing Machine For Grain Rice Granules

Automatic Granule Linear Weigher 2 Head For Long Range

Hot Labels: aluminum foil,plastic,bag,waffles,metal detection machine,food industry,dynamic,automatic,metal detector,Iran,factory,manuafacturer,supply,price