250g Automatic Packing Machine For Grain Rice Granules High Speed Stable Vertical Packaging Machine System Cheap Price

The automatic packing machine adopts a high-precision structure of 304 stainless steel, which is rust resistant, durable, and easy to operate and maintain. The grain rice granules packaging machine adopts PLC, touch screen, stepper motor control, convenient and accurate bag length setting, making packaging more convenient and smooth, simple and fast, saving time and film. Our product specifications and sizes are rich, various styles, welcome to contact us for quotation information.

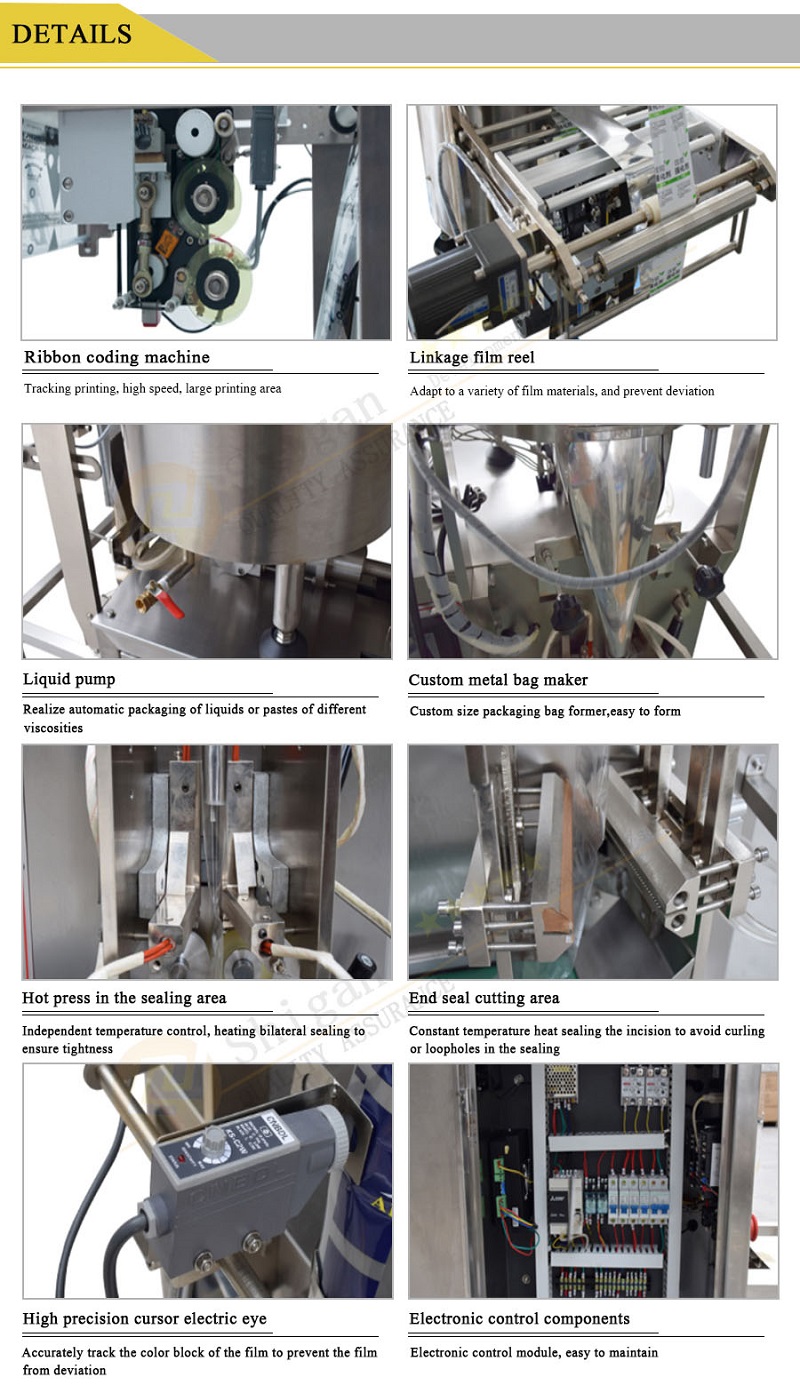

Grain rice granules packaging machine photos

Film width: maximum 320mm

Bag length: maximum 220mm

Bag width: 50-150mm

Packaging speed: 5-60 bags/minute

Measurement range: 50-500ml

Film thickness: 0.04-0.08mm

Power: 220V 50/60Hz 2KW

Machine size: 970 * 680 * 1950

Machine mass: approximately 300KG

Optional devices: date encoder, punching device (needle hole, round hole, butterfly hole), connecting bag control device, inflation device, exhaust device. Tear gap device, nitrogen inflation device, Gusset bag

The above parameters are for reference only. Our professional engineers will rigorously evaluate the characteristics, specifications, and environmental factors of the production line, and design the most suitable packaging machine solution for you to meet the different needs of various complex production lines.

The automatic packing machine can be used in the following fields:

*Food industry * Beer and beverages * Daily chemical lamps * Pharmaceuticals

*Mold Hardware Industry * Plastic Rubber * Express Logistics * Communication

*Household appliance industry * Seafood breeding * Seafood processing * Poultry products

*Traditional Chinese * Agricultural Chemicals * Paint Industry * Automobile * Pharmaceutical Processing

Workflow: (configuration can be customized according to customer products)

1. Bag loading: The bag is delivered to the machine clamp using an up and down method, with no bag warning, reducing personnel and labor intensity;

2. Print production date: ribbon detection, shutdown alarm when ribbon is used up, touch screen display to ensure normal coding of packaging bags;

3. Opening the bag: Opening the bag for inspection, ensuring that no materials are lost without opening the bag;

4. Filling materials: inspection, materials are not filled or heat sealed, ensuring no waste of bags;

5. Heat sealing: temperature abnormal alarm to ensure sealing quality

6. Cooling shaping and discharge: ensure beautiful sealing

1.13 years of experience in packaging machine manufacturing.

2. Over ten years of technical team building, we have a high-quality team with over 30% professional technical personnel. Product design updates and rich experience in personalized product industry requirements.

3. A professional foreign trade team, with a sales team of over 20 people, each employee has rich market sales experience and provides high-quality pre-sales online communication services.

4. A professional after-sales service team with a 2-year warranty period is willing to establish long-term cooperative relationships with every customer.

5. We cooperate with multiple logistics companies to safely and quickly deliver goods to customers, minimizing their logistics costs.

6. Regularly participate in large-scale industry exhibitions in various regions and have the ability to negotiate cooperation with regional partners.

Packing Detail:

Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.

Delivery Detail :

Shipped in 25 days after payment

A. Pre-sale:

1. Provide real quotations for customers according to customer requirements, and record feedback in a timely manner if customers have special requirements;

2. Sign a standardized product order contract to clarify responsibilities and other related matters;

3. Provide one-year free warranty, life-long maintenance service, and be responsible for debugging the product before delivery;

B. After sales:

1. If the customer's product fails, we will solve the problem for you as soon as possible

2. During the warranty period, product maintenance is free. After the warranty period, maintenance can also be provided. If the accessories are replaced, the product accessories will be provided at the cost price.

Related Products

Automatic Granule Linear Weigher 2 Head For Long Range

Anti-seismic Food Metal Detector System Cheap Price

100ml Semi-automatic Food Industry Liquid Filling Machine

Spices Powder Sachet Packaging Machine With 4head Linear Weigher

High Speed Boxed Medicine Mini Check Weigher

300g Black Tea Automatic Combination Multi Head Weigher

Hot Labels: 250g,automatic packing machine,grain,rice,granules,high speed,stable,vertical packaging machine,packing machne system,cheap,price,manufactures