20kg Industrial Carton Belt Roller Conveyor Checkweigher Embedded Flexible Customized Automatic Check Weigher Price

Check weigher as known as checkweigher, check weight machine, check weighing machine, weight sorting machine, weight checker, and etc,.

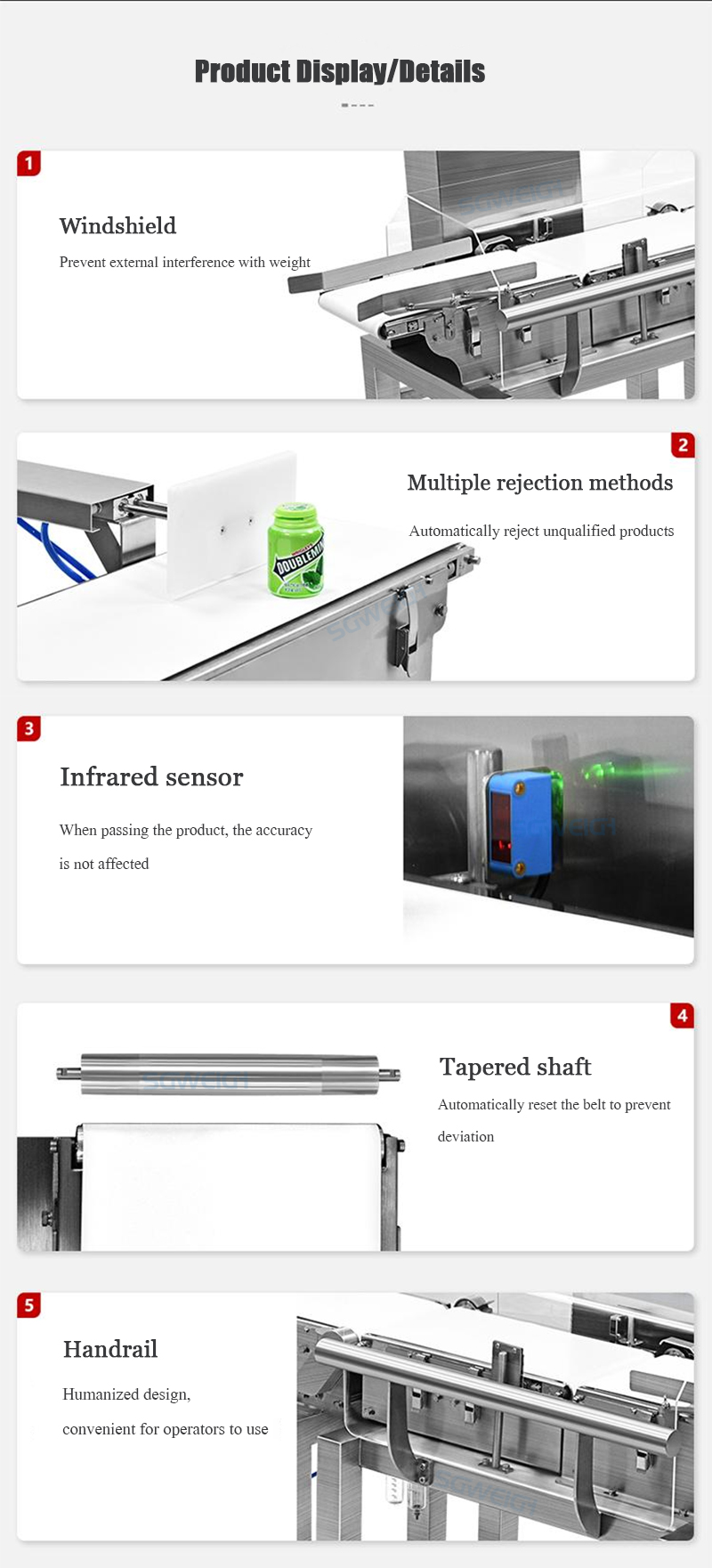

The industrial automatic check weigher is used to detect whether the weight of a single (or a box) product matches the set target. The continuous dynamic automatic weighing method detects the weight of items, and is equipped with an automatic removal mechanism to achieve high-speed and high-precision weight detection and sorting on the assembly line. The unique low center of gravity design of the carton roller conveyor checkweigher greatly reduces the impact of vibration, thereby improving detection accuracy. For further information about our services, or if you would like one of our professionals to contact you, please do not hesitate to contact us.

Industrial automatic check weigher photos

1. Accuracy

Imported high-speed weighing modules and weight sensors can be used to ensure the accuracy of calibration.

2. Structure

Simple and compliant with GMP and HACCP standards, all made of stainless steel, with a simple structure and easy maintenance and upkeep.

3. Convenient operation

Adopting Schneider touch screen, easy to operate, intuitive display, support for multiple languages (default Chinese and English).

4. Convenient external connection

Industrial automatic check weigher can be connected to other devices in the production line, such as printers, labeling machines, and inkjet printers (customized by customers).

5. Wide application

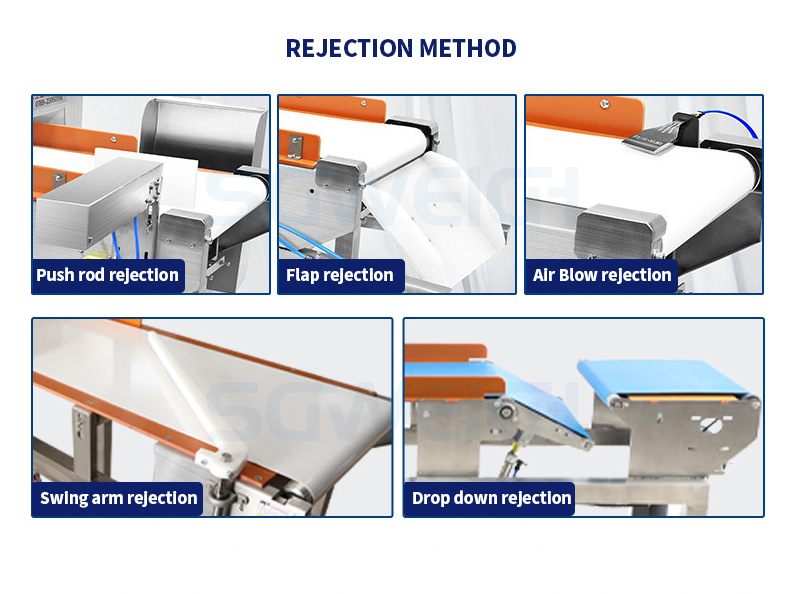

Suitable for checking the weight of packaging bags and filling packaging, there are multiple removal methods to choose from (pull, blow, push plate, etc.).

6. Automatic feedback function

Provide signals to the front-end and provide timely feedback on packaging accuracy to adjust the feeding status of the connected equipment.

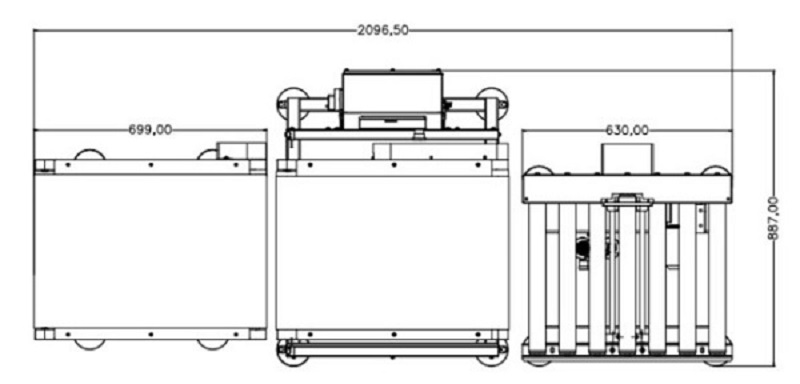

Type SG-450

Weighing Range 0.05-25kg

Limited of product L: 550 W:450 H: 3-400mm

Accuracy ±5/10g

Division Scale 1g

Belt Speed 0- 60 m/min

Max Speed 40 pcs/min

Belt Width 450mm

Machine Weight 40kg+70kg+45kg

Power Supply AC 110/220V ±10% 50HZ

Power 400W

Main Material SU304 stainless steel

The above parameter information is for reference only and can be customized according to specific requirements. Provide the following information to our sales personnel, and our team will support you in selecting the correct type of industrial automatic check weigher:

*1. Main parameters of the tested product, product size range: length, width, height

*2. Accuracy requirement: ± g.

*3. Speed requirement: pcs/min;

*4. Product weight range:; The maximum and minimum deviations of the same product.

1. Assembly line weighing detection: 1) overweight/underweight detection; 2) Full box missing parts detection; 3) Attachment missing detection.

2. Assembly line weighing and sorting: 1) multi-level weight sorting; 2) Sorting of non-conforming products; 3) Reject non-conforming products.

Shanghai Shigan Industrial Co., Ltd. was established in 2010 and is a leading high-tech company with over 13 years of experience in metal detectors. The main products include metal detectors, weighing scales, etc. Shanghai Shigan has its own research and development team, with many experienced engineers and workers designing and manufacturing metal detectors and weighing scales. Due to our professional service, high-quality products, and competitive prices, we enjoy a reliable reputation among our customers. Our main machine:automatic check weigher machines, metal detectors, vertical packing machines, auto packaging machine and a series of assemble line packing detection equipments.

-Fumigation certification for wooden packaging used for overseas shipment

-Internal plastic film wrapping protects goods from salt, wind, or damage

-Shipping terms: EXWORK, FOB, C&F, CIF sea or air freight terms

12 Months Guarantee

★ 12 months free main parts change (Please return the damaged parts by airmail)

★ Overseas engineers available (You only have to pay part of the freight)

Customization

All our machines can be customized , according to your product's features and your workshop environment, or your production line.

After-sales Service Provided

Engineers availbale to provide after-sales service overseas in order to help customers solve technical problems.

Related Products

70g Pet Food Production Line Sachet Metal Detector

Rice Pellet Automatic Quantitative Multi head Weigher

Sachet Pouch Real-time Printing Checkweigher

Peanut Pouch Packing Machine Multi-head Weigher System

Protein Powder Automatic Filling Linear Weigher

Gum Food Particle Weight Inspection Check Weigher

Hot Labels: 20kg,industrial,carton,belt,roller,conveyor,checkweigher,embedded,flexible,customized,automatic check weigher,price,weight checker,factory,manufacturer