10-Lane Inspection Capsule Checkweigher High-Capacity Capsule Check Weigher

Check weigher as known as checkweigher, check weighing machine, weight check machine, check weight machine, weight checker, weight sorting machine, weighing machine, and etc,.

With ten simultaneous weighing lanes, this 10-lane inspection capsule checkweigher can inspect thousands of capsules per minute, identifying weight deviations in real time to ensure that every unit meets stringent quality standards. Each lane of the automatic high-capacity capsule check weigher operates independently, with real-time feedback and reject functions, ensuring rejected capsules are automatically removed without affecting production, enabling an efficient, error-free workflow. You are welcome to contact us at any time for quotation.

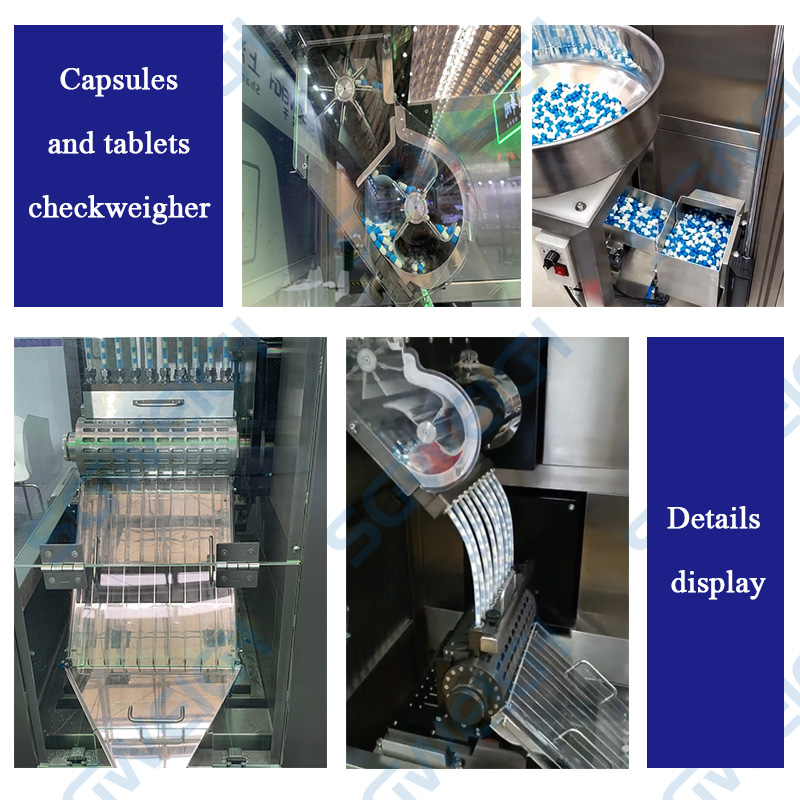

10-lane inspection capsule checkweigher photos

Flexibility to accommodate capsules of different sizes: By adjusting the weighing mechanism or using various conveying systems, the 10-lane inspection capsule checkweigher can be configured to handle capsules of different sizes, from small gel capsules to large tablets.

10-Lane Inspection Capsule Checkweigher High-Capacity Capsule Check Weigher

Equipment model CM is ±1.0-2000

Design capacity 2000 tablets/minute (120,000 tablets/hour)

Actual capacity >120,000 tablets/hour

Weighing scale 10~2000mg

Resolution 0.1mg

Dynamic accuracy ±1.0mg (actual operation accuracy ±1.0mg, minimum ±1.5mg)

Applicable materials Capsules 000#~5#, conventional tablets

Working voltage AC220V/50Hz

Control voltage DC24V

Rated power 0.6KW (main machine 0.3kw, each single machine 0.15kw)

Working pressure 0.6~0.8 Mpa

Gas consumption 0.1m³/min

Equipment weight 200kg (main machine 60kg, single machine 70kg)

Overall dimensions 740*350*1480mm (main unit width 350mm, stand-alone unit width 190mm)

1. Precision and Accuracy: Capsule checkweighers are designed to weigh each capsule with high accuracy and precision, with tolerances typically tight to ±0.1 mg.

2. High-Speed Operation: These 10-lane inspection capsule checkweighers can run at very high speeds, weighing up to 75,000 (10 lanes) capsules per hour. This makes them ideal for large-scale production environments where throughput is critical.

3. Automatic Rejection System: Capsules that are underweight, overweight, or out of specification are automatically rejected from the production line using a reject mechanism.

3. Integration with Packaging Lines: Automatic high-capacity capsule check weighers are often integrated with other systems in the production process, such as capsule filling machines, tablet presses, etc.

4. Touchscreen Interface: Capsule checkweighers come with a user-friendly touchscreen interface that allows operators to adjust settings such as weight tolerances, speed, etc. without extensive training.

5. Real-Time Monitoring and Data Logging: Checkweighers can be connected to networked systems for real-time monitoring and data logging to comply with regulatory standards such as FDA and GMP.

We support OEM/ODM. When using the capsule checkweigher system, you also need to tailor a machine that meets your needs based on the specific requirements of the capsule and the actual production environment.

10-Lane Inspection Capsule Checkweigher High-Capacity Capsule Check Weigher

Free export fumigation plywood box with quick connection design, easy to open and reuse;

Internal plastic film packaging can protect goods from salt, wind, or damage;

1. Customer consultation and technical support: Provide customers with consulting services on product use, repair and maintenance, and answer questions encountered by customers during operation and use.

2. Technical training: Provide training on product operation, maintenance and repair according to customer needs to ensure that customers can use and maintain the products correctly.

3. Accessories supply: Provide original accessories to ensure the quality and performance of accessories to meet user needs.

4. One-year warranty, lifetime maintenance

5. After-sales service tracking: Track and feedback the after-sales service process, timely understand customer needs and opinions, and continuously improve service quality.

Related Products

Strip Bar Packaging Multi-Lane Packing Machine

4-Line Bar Packge Checkweigher With Rejector

Automatic Checkweigher For Tablet Weight Sampling

Super High-Speed Box Checkweigher Solution

High-Precision #00 #01 Capsule Checkweigher

High-Speed Checkweighing for Cosmetics Industry

Automatic Rotary Checkweigher For Bottle Industrial

Vertical Metal Detector For Capsule Manufacturing

Sauce Pouch Multi-Lane Packaging Machine

Compact Food Package Metal Detection Machine

Hot Labels: 10-lane,inspection,capsule checkweigher,high-capacity,capsule check weigher,factory,manufacturer,supplier,price