SG-300U Industrial Check Weigher System 3000g Dynamic Checkweigher Price

Product Introduction

The industrial check weigher systems developed by Shanghai Shigan Production adopts advanced weighing technology and adopts a minimalist design method, which is cost-effective and ensures stable and reliable weighing accuracy and speed. The dynamic checkweigher solution can detect unqualified products that are overweight or underweight in the production line in real-time and online. Dedicated 10 inch TFT color LCD screen display, with a beautiful and simple operating interface. Our product specifications and sizes are rich, various styles, welcome to contact us for quotation information.

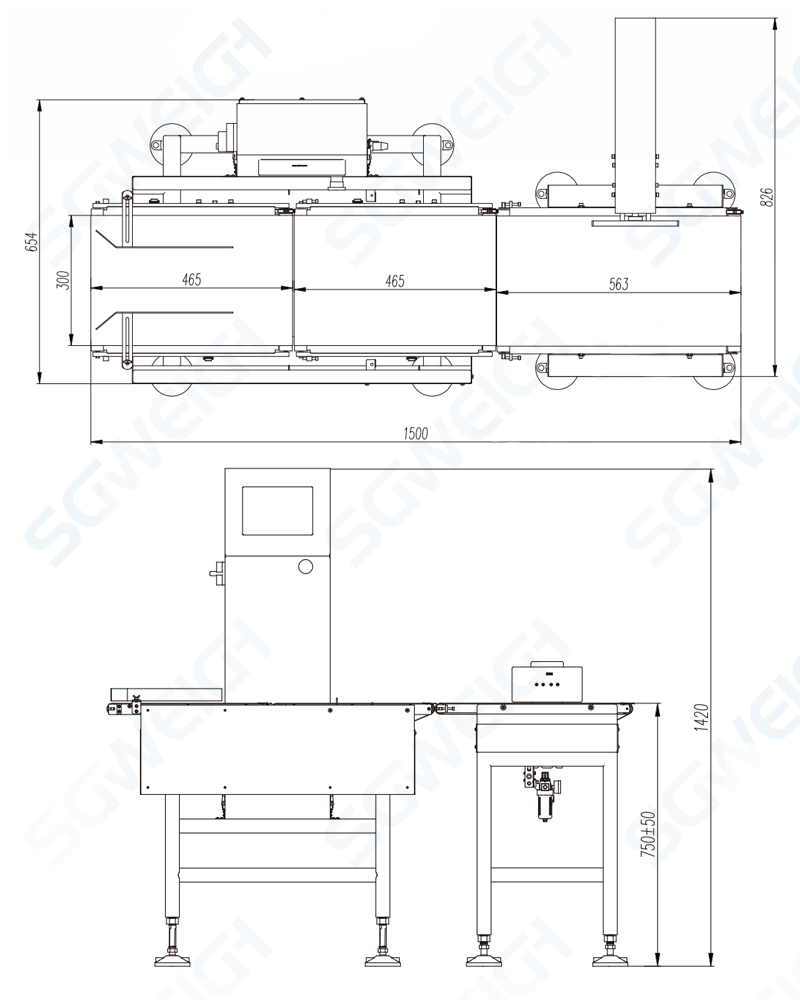

Industrial check weigher system pictures

Technical Parameter

Type SG-300U

Weighing Range 5-3000g

Limited of product L: 350 W:300 H: up3mm

Accuracy ±0.3g-0.5g Depends on product

Division Scale 0.1g

Belt Speed 0- 60 m/min

Max Speed 80 pcs/min

Belt Width 300mm

Machine Weight 85kg

Power Supply AC -220V 50HZ

Power 200W

Main Material SU304 stainless steel

Customized Process

Our company has rich experience in the manufacturing of weighing scales and can provide you with the most cost-effective industrial check weigher system solution according to your actual needs. If you need it, please feel free to contact us at any time.

Application Scope

1. Application of online weight checker for conveyer belt in the electronics and toy industry: detection of missing parts (such as detection of missing parts in toys, detection of missing parts in screw packages, detection of missing parts in products such as televisions and set-top boxes);

2. The application of online weight checker for conveyer belt in the daily chemical product industry: detecting missing cosmetics, checking if the entire bag of clothes is missing, and checking if the entire box of toothbrushes is missing;

3. Application of online weight checker for conveyer belt in industries such as hardware: detection of missing parts of stainless steel tableware and cutting tools;

4. Application of online weight checker for conveyer belt in the pharmaceutical industry: detection of drug shortage bags, absence of instructions for the entire box of drugs, and compliance with the net content of drugs;

5. Application of online weight checker for conveyer belt in the food industry: detect whether the whole box of biscuits is short of quantity when the convenient food such as instant noodles is short of material.

Main Features

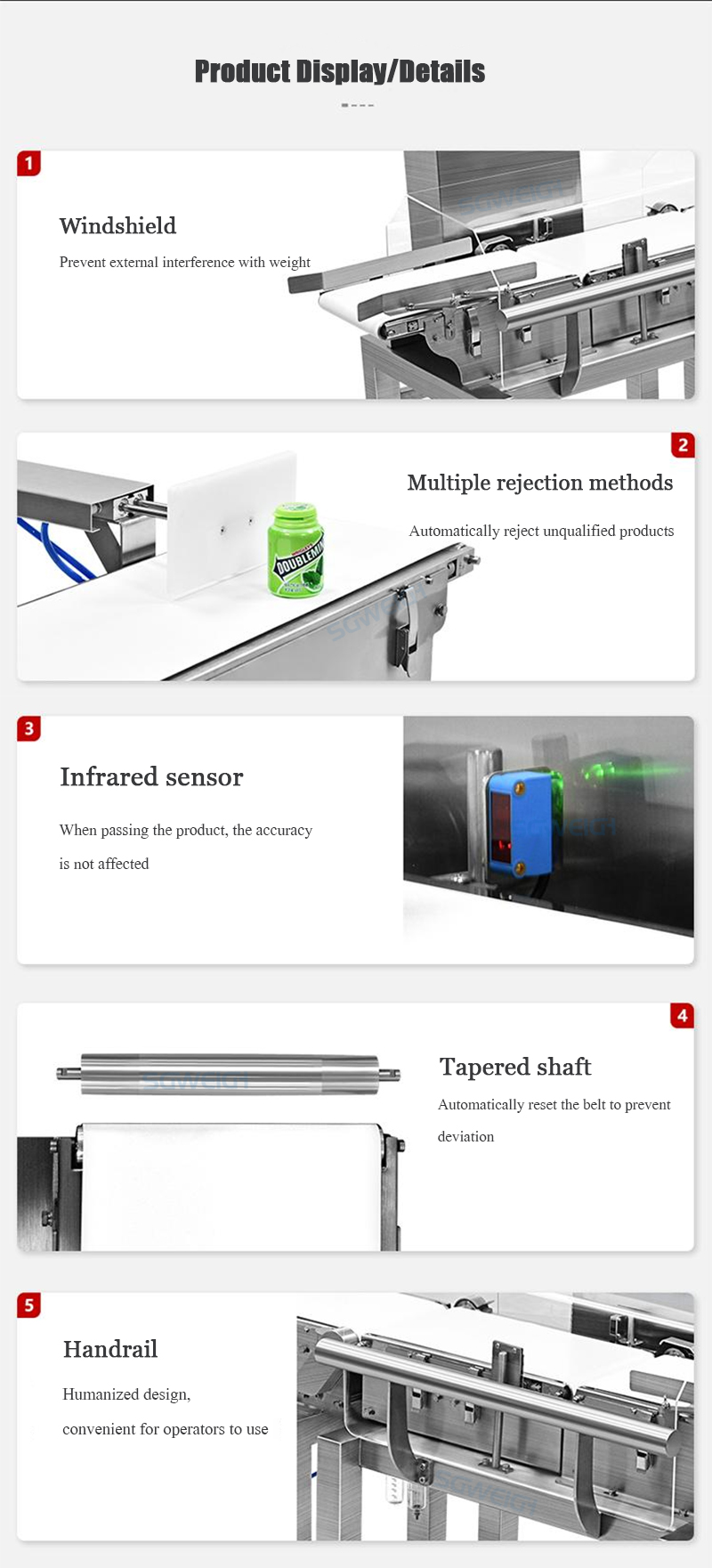

1. Long term use with guaranteed accuracy and no need for daily calibration

2. Automatic dynamic zero point tracking technology

3. Equipped with built-in hinge design, there are no safety dead corners, and the belt can be quickly installed and disassembled, making it easy to clean and maintain

4. Professional human-machine interface design

5. Simple user parameter settings, automatic parameter adjustment, just input product parameters and weighing requirements to complete parameter settings

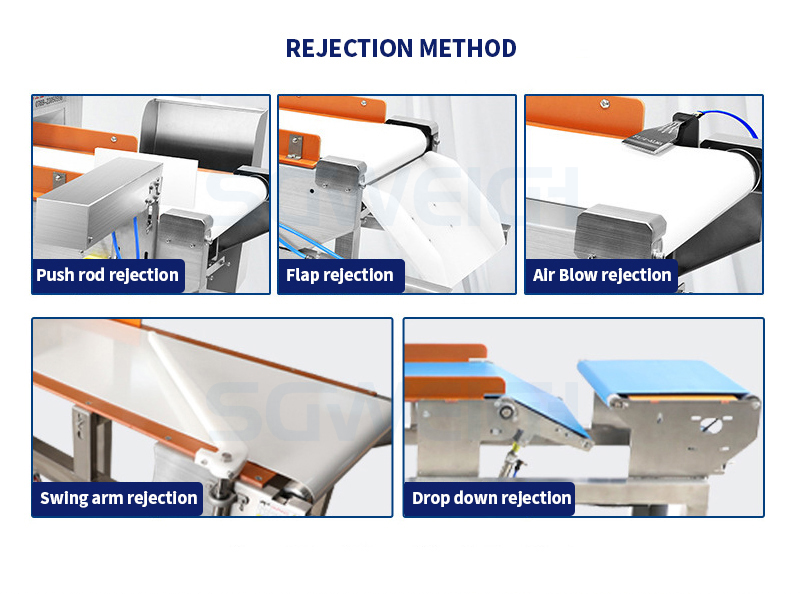

6. Accurate and efficient elimination mechanism

7. Humanized function, product database can store 1000 products

8. Password protection function ensures that unauthorized personnel cannot change data

9. Equipped with data statistics function, supporting data export, USB and Ethernet interfaces

Product Details

Company Profile

Our company introduction

Established in 2010.

2. High tech enterprises in Shanghai.

3. We have over 10 years of experience in the field of dynamic checkweigher machinery and have our own factory, which can provide you with the most suitable projects for your needs.

4. 6-8 international machinery exhibitions per year.

5. Supply OEM/ODM manufacturing.

6. Multiple engineers to ensure quality/service.

As manufacturers and traders, we have good quality and price control over our products.

7. The products are exported to over 40 countries such as the United States, Canada, and Mexico; Australia, New Zealand; Saudi Arabia, Italy, Spain; France, Poland, Israel, Russia, South Korea; Thailand, Indonesia, Malaysia, Philippines, etc

8. Our main products

Capsule and Tablet Checkweigher

Checkweigher and Labeling Machine Combo

Checkweigher and Metal Detector Combo

Our Customers

Our Exhibition

Packing & Shipping

1. Packaging materials: International standard export packaging boxes are usually used, which have good wear resistance, shock resistance, and waterproof performance. The material of the box can be hard wooden boxes, plastic boxes, or export specific cardboard boxes.

2. Protective measures: In order to ensure that the weigher is not damaged during transportation, it is necessary to add sufficient filling materials, such as foam, shockproof cotton, etc., into the packaging box.

3. Identification and Marking

After-sale Service

12 Months Guarantee

★ 12 months free main parts change (Please return the damaged parts by airmail)

★ Overseas engineers available (You only have to pay part of the freight)

Customization

All our machines can be customized , according to your product's features and your workshop environment, or your production line.

After-sales Service Provided

Engineers availbale to provide after-sales service overseas in order to help customers solve technical problems.

Related Products

Professional Ultra High-speed Weighing Checkweigher Solution

50kg Gypsum Industrial Checkweigher Metal Detector Combo

Liquid Milk Dynamic Bag Sachet Metal Detector

Round Bottles Weighing Labeling Machine with Date Printing

Multi-lane Checkweigher For Small Strippack Sachet

Automatic Conveyor Belt Metal Detector For Food Industry

Hot Labels: 5-1500gm,online,weight checker,check weighing machine,checkweigher,conveyer belt,small business,dynamic checkweigher,manufacturer,China