Rotary Turntable Checkweigher For Bottle Production Line Check Weigher Machine

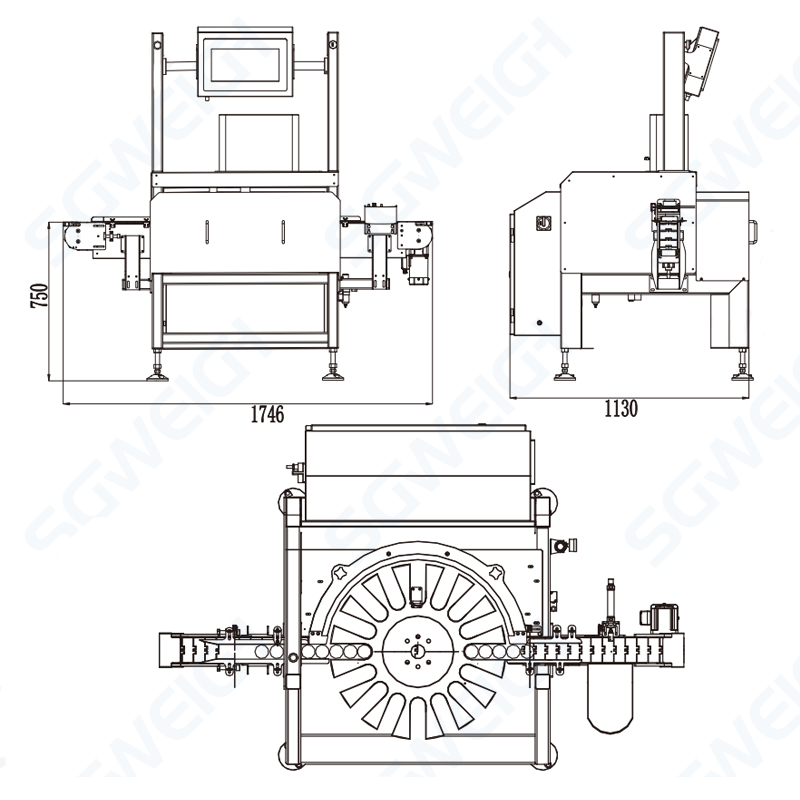

The rotary turntable checkweigher for bottle adopts a turntable structure design, using an alternating feed rotation system to position and stabilize the product on the static weighing plate, providing the best accuracy and repeatability at high production speeds and saving space. The bottle production line check weigher is mainly composed of front chain feeding, clamping turntable, weighing module, discharge chain plate, and rejection. Photoelectric positioning, the turntable accurately delivers the product to the weighing sensor. Our products have a wide range of specifications, sizes, and styles, providing various customized solutions. Welcome to contact us.

Rotary turntable checkweigher for bottle photos

Type SG-Z

Weighing Range 2-300

Restrictions of Products:φ10-100 H:20-200mm

Limited of product L: 180 W: 40 H: 2-20mm

Accuracy ±0.01g Depends on product

Division Scale 0.01g

Belt Speed 0- 50 m/min

Max Speed 60 pcs/min,120 pcs/min,180 pcs/min(optinal)

Belt Width 100mm

Machine Weight 260kg

Power Supply AC 110/220V ±10% 50HZ

Power 400W

Main Material SU304 stainless steel

We accept various customization and logos on all our products for customers.

If you are interested, please contact us

If you want to know more related products, more surprises are waiting for you~

Rotary Turntable Checkweigher For Bottle Production Line Check Weigher Machine

1. Improve production efficiency: Rotary turntable checkweigher for bottles can automatically and quickly weigh and sort items, greatly improving the efficiency of the production line and reducing the time and errors of manual operation.

2. Ensure product consistency: Through accurate weighing, checkweighers help ensure the consistency of product weight, improve product quality, and meet customer needs and industry standards.

3. Reduce waste: Rotary turntable checkweigher for bottlers can promptly detect and sort items that do not meet the weight requirements, reduce the circulation and waste of unqualified products, and reduce costs.

4. Improve weighing accuracy: Rotary turntable checkweigher for bottle use high-precision weighing sensors to provide more accurate weighing results, which helps companies to conduct precise inventory management and quality control.

5. Easy to integrate: Bottle production line check weighers can easily integrate with existing production lines and automation systems to achieve unmanned or automated production lines with reduced human intervention.

6. Flexibility and adjustability: bottle production line check weighers can usually adjust the weighing range and sorting standards to meet the production needs of different products, and have good flexibility.

7. Data recording and analysis: Modern bottle turntable check weighers usually have data recording functions, which can store and analyze weighing data to help companies track quality and improve production processes.

8. High reliability: The design and manufacture of the rotary turntable checkweigher for bottle focuses on stability and reliability, and can maintain accuracy and stability in continuous operation, reducing failures and maintenance costs.

9. Space saving: Compared with traditional manual weighing methods, the checkweigher can be installed more compactly on the production line, saving production space.

10. Strong adaptability: The Rotary turntable checkweigher for bottle can adapt to different working environments, including harsh temperature, humidity, vibration and other conditions, and can maintain normal operation in a variety of environments.

Rotary turntable checkweigher for bottles are widely used in many industries such as pharmaceuticals, food, beverages, daily chemicals, light industry, electronics, hardware, industrial products, Chinese medicinal materials, aquatic products, poultry, fruits and vegetables, logistics, etc.

Rotary Turntable Checkweigher For Bottle Production Line Check Weigher Machine

1: Lubricate the drive unit

2: Divide the machine into modules

3: Wrap the modules with plastic film

4: Pack the modules into cartons

5: Make shipping marks

If there are any special requirements, we will pack according to your requirements.

1. Training services:

We will train your engineer to install our weigher.You can send your engineer to our factory or we dispatch our engineer to your company.We will introduce your engineer how to install the weigher and how to fix problem.

2. Trouble shooting service:

Some times if you can not fix the problem in you contry,we will seed our engineer there if you need us to support.Of course,you need to afford the round trip flight ticket and accommodation fee.

3. Spare parts relpacement:

For spare parts support: For machine in guarantee period,if spare part broken,we will send you the parts free and we will pay the express fee,And please send us the spare part back,when machine is out of guarantee period,we will provide you the spare parts in cost price.

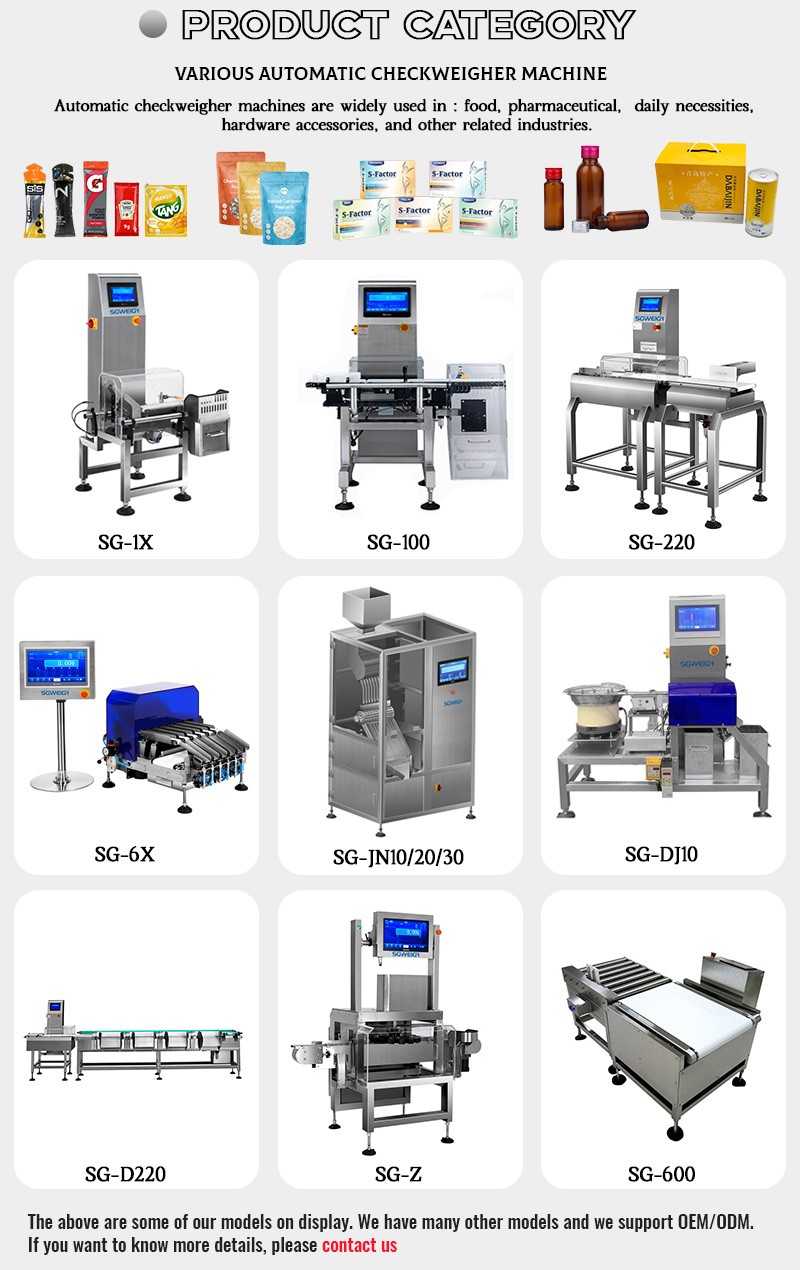

Related Products

Hairy Crabs Multi-Level Weight Sorting Checkweigher

Online Nut Sachet Checkweigher With Rejection

Probiotics Powder Multi-Row Packing Machine

Professional Capsule And Tablet Checkweigher

Meat Paste Pipeline Conveyor Metal Detector

Touch-Sensitive Boxed Spices Weight Checking System

High Speed Plastic Box Checkweigher

High-Capacity Check Weigher For Petfood Bags

Automatic Metal Detector For Frozen & Dry Food

Industrial Conveyor Belt Metal Detector

Hot Labels: rotary turntable,checkweigher,bottle,production line,check weigher machine,supplier,factory,manuafcturer,price