Quantitative Industrial Checkweigher Roller Conveyor With USB Output

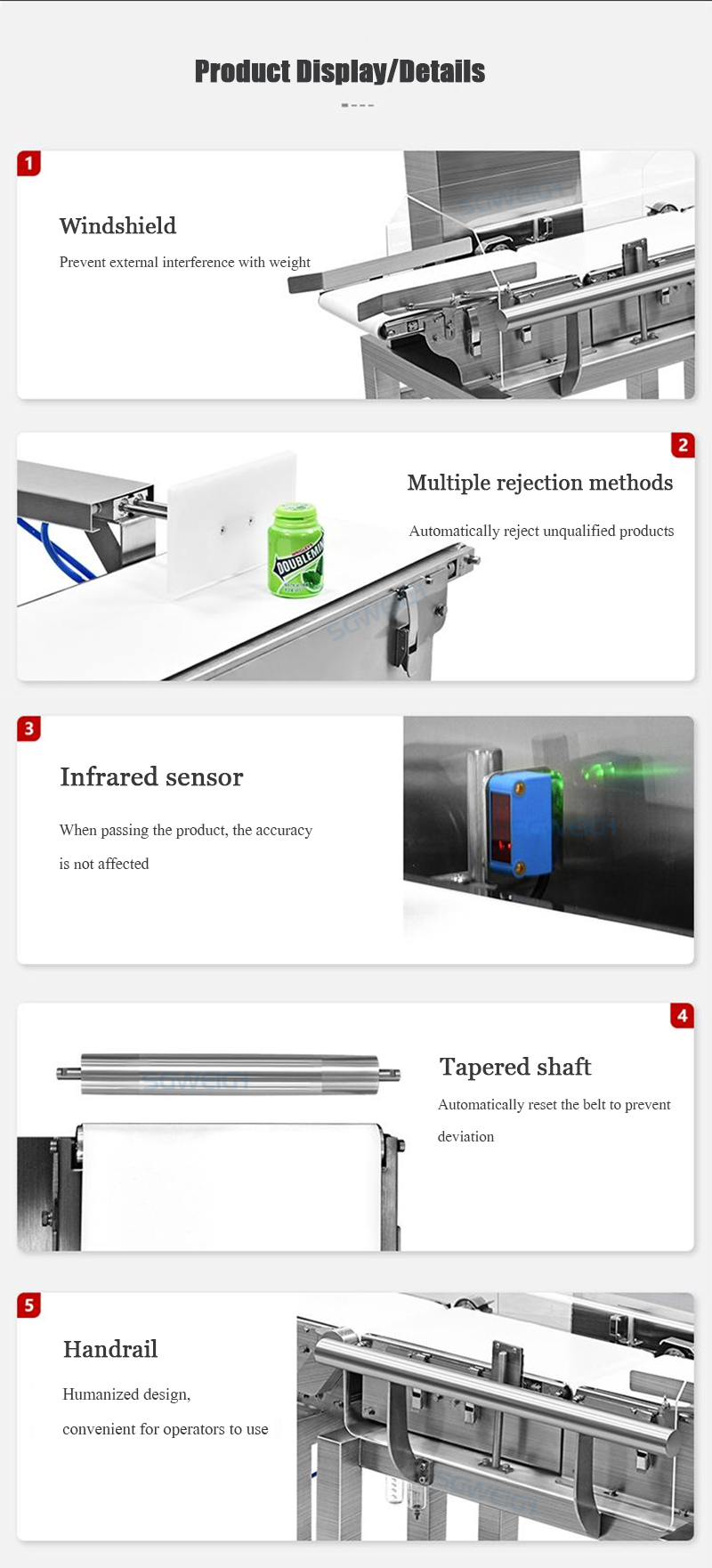

The industrial checkweigher is equipped with advanced sensors and weighing sensors, equipped with an ultra fast processor, with excellent accuracy and speed. The touch screen operating system is easy to use and comes with user password protection. The quantitative automatic checkweigher has a flexible modular structure, with a complete machine made of 304 stainless steel and a detachable belt that is easy to disassemble for cleaning and setting. Our products have a wide range of specifications, sizes, and styles, providing various customized solutions. Welcome to contact us.

Industrial checkweigher photos

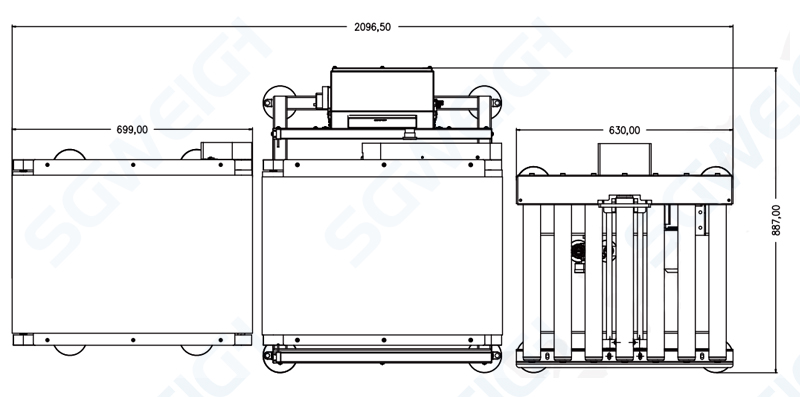

Type SG-450

Weighing Range 0.05-20/30kg

Limited of product L: 500 W:450 H: 3-400mm

Accuracy ±1g

Division Scale 0.1g

Belt Speed 0- 40 m/min

Max Speed 40 pcs/min

Belt Width 450mm

Machine Weight 100kg

Power Supply AC 110/220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

1. The minimum speed and accuracy of weight inspection vary depending on the actual product being tested.

2. The standard model is only for selection reference, and the specific parameter requirements are customized according to the actual needs of users.

3. Selection: Pay attention to the direction of movement of the product on the belt. If the product is transparent or semi transparent, please inform our company.

1. Ultra high adaptability to equipment environment.

2. Extremely user-friendly operation interface.

3. You can modify parameters at any time without the need for the weight sorting machine to pause sorting.

4. Up to 200 product presets can store hundreds of thousands of data records, meeting the complex needs of customers.

5. Rich peripheral resources make it easy to connect with other devices.

6. The rapid dynamic weighing algorithm software technology enables the entire system to maintain high detection accuracy even during high-speed operation.

1. Assembly line weighing detection: 1) overweight/underweight detection; 2) Full box missing parts detection; 3) Attachment missing detection.

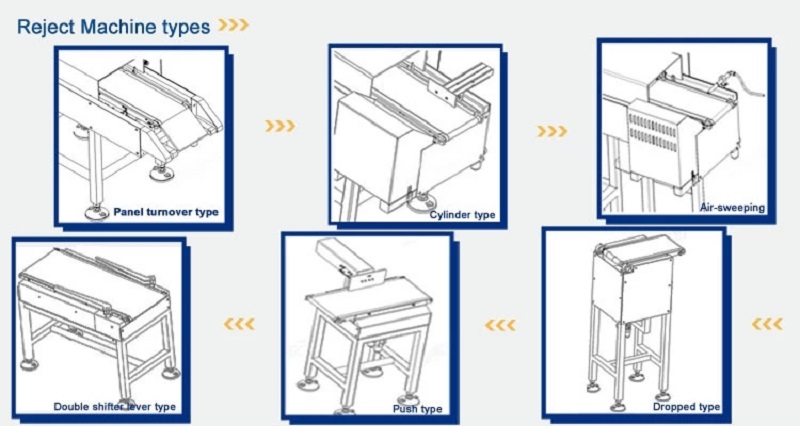

2. Assembly line weighing and sorting: 1) multi-level weight sorting; 2) Sorting of non-conforming products; 3) Reject non-conforming products.

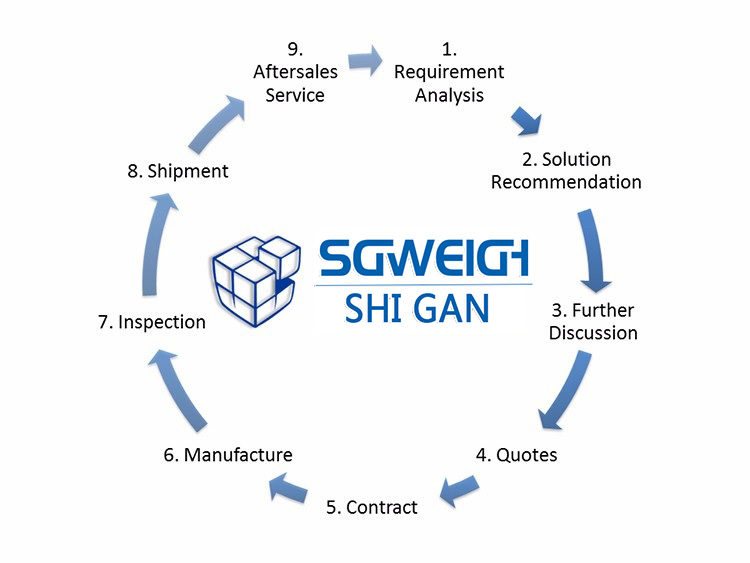

The Delivery Date: After receiving the payment, the delivery date will be within 15-30 working days

Packaging: Protective film + wooden case

Logistics: Air, sea or express (DHL, etc.)

The Freight: The cost of transport depends on the destination, mode of transport and the weight of the goods

Pay: T/T, Western Union, paypal

Our manufacturer has ISO9001, CE international certification,

More than 14 years of production experience

More than 14 years of foreign trade experience

More than 20 national technology patents

Cumulative overseas sales exceed 1,000 sets

Comply with EN60204 international standard

Our main products

Capsule and Tablet Checkweigher

Checkweigher and Labeling Machine Combo

Checkweigher and Metal Detector Combo

12 Months Guarantee

★ 12 months free main parts change (Please return the damaged parts by airmail)

★ Overseas engineers available (You only have to pay part of the freight)

Customization

All our machines can be customized , according to your product's features and your workshop environment, or your production line.

After-sales Service Provided

Engineers availbale to provide after-sales service overseas in order to help customers solve technical problems.

Related Products

Automatic Weighing Printing Conveyor Line Checkweigher

Double Bottle Rotary Weighing Checkweigher System

SG-400 Online Box Checkweigher for 10kg Conveyor

SG-300U 3000g Packaging Line Checkweigher Machine

10 Lines High Sensitivity Food Multi-line Checkweigher

Bag Pouch Medicine Tunnel Metal Detector

Hot Labels: quantitative,industrial checkweigher,roller,conveyor,checkweigher,usb output,manufacturer,factory,price