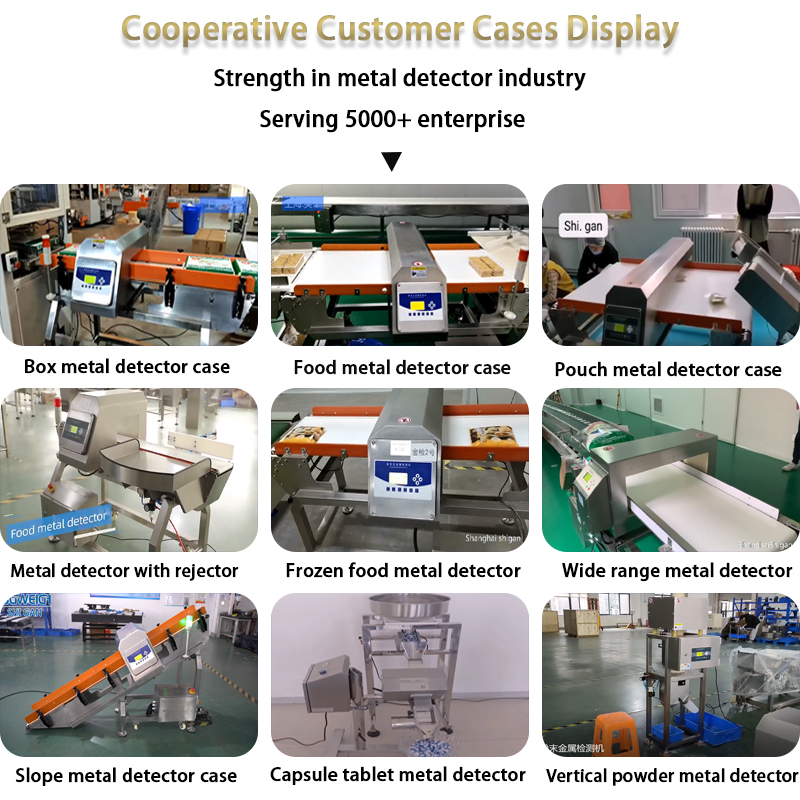

Pharmaceutical Compact Capsule Metal Detector High-Precision Metal Detection

This high-precision compact capsule metal detector has high accuracy and fast processing capabilities, and can detect even the smallest ferrous and non-ferrous metal contaminants, including metal particles such as stainless steel, aluminum foil, copper, etc. The pharmaceutical capsule metal detector is designed with pharmaceutical grade stainless steel and tool-free components for easy cleaning and routine maintenance. The compact size enables metal detection even in space-constrained environments. You are welcome to contact us at any time for quotation.

High-precision compact capsule metal detector photos

1. High Sensitivity and Accuracy: Capable tablet of detecting the smallest metal particles (typically as small as 0.3mm (ferrous metals) and 0.5mm (stainless steel) to ensure tablets and capsules meet stringent purity standards.

2. Reject System: When contaminated capsules tablets are detected, the machine automatically rejects the defective product using a reject mechanism such as an air jet or pusher, ensuring only uncontaminated product moves forward.

3. Hygienic Design: Made of stainless steel with a smooth surface, it meets the strict hygiene standards of the pharmaceutical industry. The design minimizes the risk of contamination and ensures easy cleaning.

4. Compact Size: High-precision compact capsule metal detectors are typically compact and easy to integrate into small production spaces without major modifications.

5. User-Friendly Interface: Features an intuitive touchscreen interface for easy setup, operation and adjustment of parameters. The interface allows the operator to monitor performance, adjust sensitivity levels and access data logs.

Feed port height and size: Height: 770-930mm Feed port size: 76mm

Height and size of outlet: Height: 770-860mm Size of outlet: 51mm

Effective passing size: W70*H20mm

Maximum production capacity: 500,000 pcs/hour

Detection sensitivity: Fe: 0.4mm, stainless steel: 0.6mm

Machine weight: 75kg

Removal method: flip culling

Working voltage: 220V/110V, 50/60HZ

Equipment dimensions: 1115*550 (1280-1400) mm

Tablet production: Used during tablet compression to detect metal contaminants before tablet packaging to ensure product safety and quality.

Capsule inspection: Ensure that capsules are free of metal contaminants after sealing but before final packaging.

Pharmaceutical Compact Capsule Metal Detector High-Precision Metal Detection

1. Sensitivity settings: The sensitivity of the high-precision compact capsule metal detector can be adjusted based on the type of metal contamination and particle size being targeted.

2. Product-specific settings: Different product formulations (e.g. tablets with metal coatings) may require specific settings to reduce false positives. Customization allows for optimal detection based on product characteristics.

3. Customization of reject mechanisms: The reject system can be customized based on product type and packaging format. For fragile tablets or capsules, a gentler reject mechanism can be used to avoid product damage.

4. Integration with production lines: Pharmaceutical capsule metal detector can be customized to fit existing production lines, with the option to integrate seamlessly with tablet presses, encapsulation machines or blister packaging systems.

Pharmaceutical Compact Capsule Metal Detector High-Precision Metal Detection

1> Attach safety labels, tighten screws, clean, lubricate, and prevent rust;

2> Disassemble into packages;

3> Wrap tightly with plastic film;

4> Fix in plywood box

5> Forklift into container

Suitable for long-distance land and sea transportation. In order to safely load and unload to the destination, we recommend that you choose full container transportation.

1. Seven-day replacement, one-year warranty, and lifelong maintenance. Before the product is sold, we will conduct a strict inspection, and the product you sign for has no quality problems.

2. The products provided to customers are all original products and have original data accessories.

3. During the warranty period, our company is responsible for repairing accessories damaged due to quality reasons. If the accessories are damaged outside the warranty period, the accessories provided will only be charged at cost. If the equipment is damaged due to human factors, the accessories repaired or provided by our company will be calculated at cost.

ReLated Products

Sachet Multilane Sauce Filling Packing Machine

Foil-Wrapped Medicine Package Metal Detection Machine

High Accuracy Hard Capsule Checkweigher

Inline Bulk Tea Powder Metal Detector

Automatic Weight Checker For Food Package

Bulk Cinnamon Spices Metal Detector

High-Precision Twin-Lane Checkweigher

Probiotics Liquid Multi-Lane Packaging Machine

Heavy-Duty Automatic Check Weigher Machine

Coffee Sachets Multi-Track Checkweigher

Hot Labels: pharmaceutical,compact,capsule metal detector,high-precision,metal detection,manufacturers,supplier,factory,price