Products Information

The contact parts of the multi-function auto packing machine and materials are made of SUS304 stainless steel. The single-chip microcomputer liquid crystal display screen is intelligently controlled. The fault alarm and circulating wind power control box are designed for 24-hour work and frequency conversion speed regulation. The chemical industry packing machine complies with the EU CE certification standard, and has fully automatic completion of bag making, measuring, filling, sealing, cutting and counting.For further information about our services, or if you would like one of our professionals to contact you, please do not hesitate to contact us.

Technical Parameter

Product Name: Automatic Packaging Machine

Chassis material: 304 stainless steel

Bag width: 50-12mm

Bag making length: 60-180mm

Machine weight: 350kg

Dimensions: 650*700*1700mm

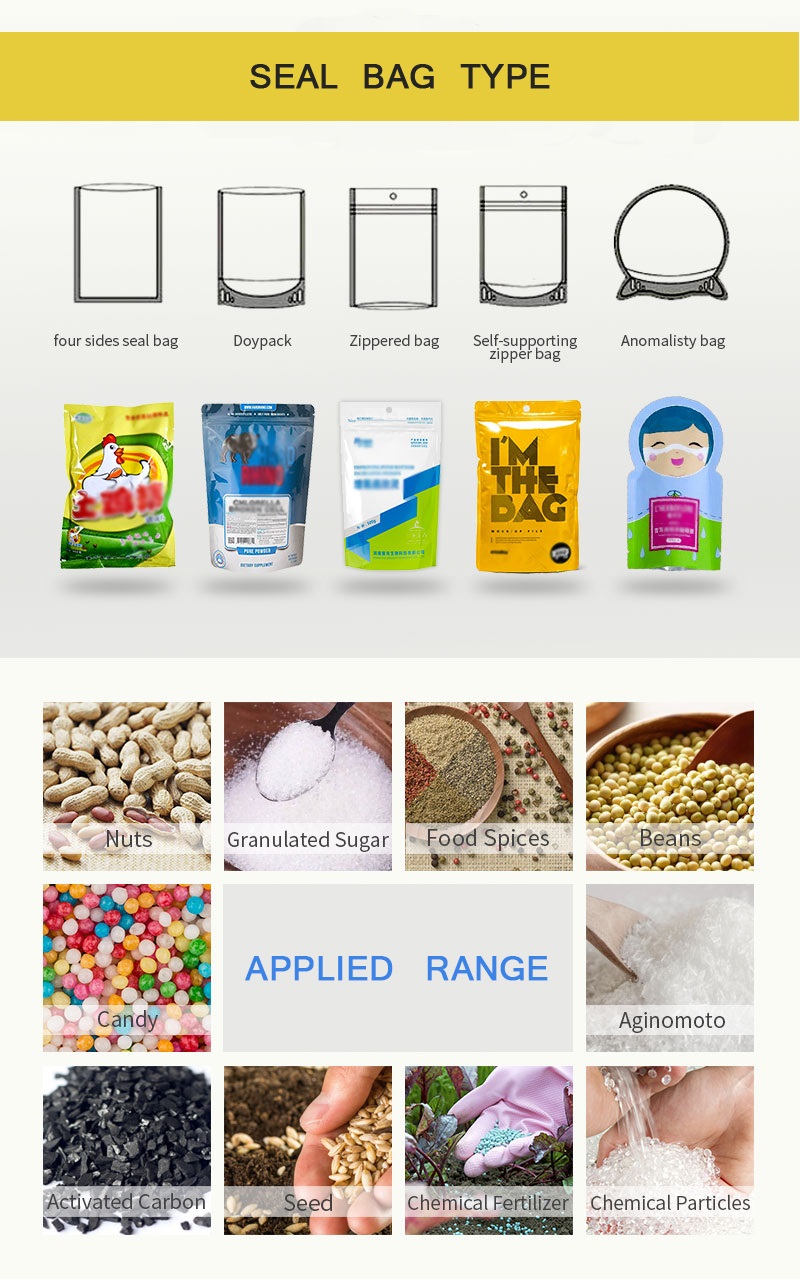

Sealing method: back seal (other sealing methods can be customized)

Packaging materials: aluminum foil film, non-woven fabric, filter paper, composite film, etc.

Features: bag making, filling, counting, sealing, slitting, outputting finished products, labeling, printing

Application

This automatic packing machine is a fully automatic packaging machine, which integrates machine, light, electricity and gas. It is only necessary to select different metering and filling devices according to different materials. It is suitable for materials of various shapes, states and properties, such as: large and small particles, powder, sauce, liquid material, etc. liquid, hot pot base, etc.)

Main Advantages

1. This automatic packaging machine can automatically complete the functions of automatic measurement, automatic filling, automatic bag making (printable), sealing and cutting of product fixed packaging.

2. Adopt advanced technology, humanized design, Japan "Siemens" PLC+5.7" touch screen control system, high degree of automation.

3. Self-alarm, self-shutdown, self-diagnosis, safe and simple to use, fast maintenance, automatic display of the number of packages, convenient to count the workload of the machine.

4. Using the working principle of heat-sealing and pulling the film, the motor controls the film, and the bag is pulled quickly and smoothly.

5. High-sensitivity photoelectric sensor switch, which can automatically track and locate the printing cursor. When packaging materials with color labels, a full logo pattern can be obtained.

6. The integrated support frame is adopted, which is more convenient to adjust.

7. The whole machine is made of 304 stainless steel and aluminum alloy (comply with GMP standard).

Customized

The product demonstrating may not perfectly meet your requirements,our philosophy is to customize your real need.

To minimizing idle capacity and function. To supply you performance and cost balanced products. Following are the factors shall be taken into account during customization:

1,Products to be packed

2,Container to be filled, type and specification.

3,Capacity requirement

4,Automation requirement

5,Protection requirement

6,Other specific requirement

Our Company

Our manufacturer has ISO9001, CE international certification,

1. More than 11 years of production experience

2. More than 10 years of foreign trade experience

3. More than 10 national technology patents

4. Cumulative overseas sales exceed 1,000 sets

5. Comply with EN60204 international standard

After Sale Service

Over the years, Shanghai Shigan Industrial Co,.Ltd has been serving customers in various industries and has concluded a complete product service guarantee system through research and exploration, providing users with high-quality and timely pre-sale, in-sale and after-sale services:

1. Quality Assurance

Shanghai Shigan Industrial Co,.Ltd guarantees that the electronic scales provided to customers are produced by the original factory, and the factory data and accessories are complete. In order to maintain the normal operation and maintenance of the contract equipment, our company guarantees that the technical products provided are complete, clear and correct.

2. Quality assurance measures

Warranty Period: On-site service is provided during the warranty period.

(1). The company has an after-sales service center, which is mainly responsible for after-sales service and technical consultation. It is guaranteed that engineers are always available to provide various technical services.

(2). There are remote services on the Internet to solve various problems in a timely manner, and provide real-time online services all year round.

Vulnerable parts: the company spares the stock of various commonly used parts to ensure that the problem can be solved in a short time.

Related Products

High Speed Automatic Filling Oil Liquid Packing Machine

500g Milk Chilli Powder Sachet Packing Machine

Automatic Packing Machine Pouch Packaging

Packing Machine with Multiheads Weigher Weighing System

Higher Accuracy High Speed Check Weigher System

Granule Chips Rice Weighing Filling Multihead Weigher

Hot Labels:multi-function,cheap,price,pouch,packing machine,chemical,industry