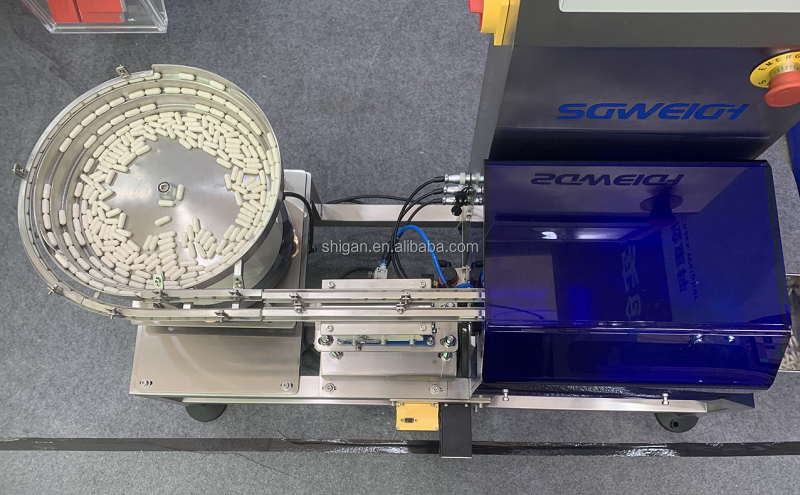

Intelligent Capsule Tablet Sample Checkweigher for Precise Weight Control

Check weigher as known as checkweigher, check weighing machine, weight check machine, check weight machine, weight checker, weight sorting machine, weighing machine, and etc,.

The front end of the intelligent capsule tablet sample checkweigher can be connected to the tablet press or filling machine, and part of the material can be taken regularly or irregularly. Through vibration, sorting and weighing, qualified products continue to flow in the assembly line, and unqualified products are removed from the side. The accuracy is 1-2mg and the speed is 100-150pcs/min. Sample checkweigher for precise weight control helps to monitor the status of the drug production process, record sample data and issue abnormal alarms, so as to control production more effectively. To know more about us, please you do not hesitate to contact us or visit our factory.

Sample checkweigher for pills tablets and capsules photos

Type SG-DJ10

Weighing Range 20-2000mg

Limited of product L: 100 W: 100 H: 2-150mm

Accuracy ±1mg Depends on product

Division Scale 1mg

Each Channel Speed 100 pcs/min

Machine Weight 80kg

Power Supply AC -220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

Intelligent Capsule Tablet Sample Checkweigher for Precise Weight Control

Features

High precision: With extremely high weighing accuracy, it can detect small weight differences.

Quick detection: Intelligent capsule tablet sample checkweigher can quickly complete the weight detection of capsules without affecting the normal operation of the production line.

Easy to operate: Usually equipped with an intuitive operation interface, which is convenient for operators to use.

Good stability: Intelligent capsule tablet sample checkweigher adopts a stable mechanical structure and high-quality sensors to ensure the accuracy of the weighing results.

Function

Sampling detection: The sampling ratio can be set, and capsules can be automatically or manually extracted for weight detection.

Weight classification: According to the set weight range, capsules are divided into qualified and unqualified categories.

Data recording: Automatically record the detection data for quality control and traceability.

Rejection of unqualified products: For capsules with unqualified weight, they can be automatically or manually rejected.

The intelligent capsule tablet sample checkweigher is a precision weighing device specially used for weight detection of capsule tablets pills dosage form products in the pharmaceutical industry. It is used to sample and inspect capsule tablets pills in the production line to ensure that the weight of each capsule tablet pill meets the specified standard.

The product demonstrating may not perfectly meet your requirements,

our philosophy is to customize your real need.

To minimizing idle capacity and function. To supply you performance and cost balanced products. Following are the factors shall be taken into account during customization:

1,Products to be packed

2,Container to be filled, type and specification.

3,Capacity requirement

4,Automation requirement

5,Protection requirement

6,Other specific requirement

Intelligent Capsule Tablet Sample Checkweigher for Precise Weight Control

1. Packaging materials: Usually international standard export packaging boxes are used, which have good wear resistance, shock resistance and waterproof performance. The box material can be hard wooden boxes, plastic boxes or export-specific cartons.

2. Protective measures: To ensure that the machine is not damaged during transportation, it is necessary to add sufficient filling materials such as foam, shockproof cotton, etc. in the packaging box.

Over the years, Shanghai Shigan Industrial Co., Ltd. has been serving customers in the melt industry, after research, exploration, summed up a complete set of product and service support system to provide users with high quality and timely pre-sale, sale, after-sales service:

First, quality assurance

My business department to ensure that the equipment provided to customers is the original production, and factory information accessories complete. In order to maintain the normal operation and maintenance of the contracted equipment, the technical products provided by our department are complete, clear and correct.

Second, quality assurance measures

Warranty period: one year warranty and lifetime maintenance. During the warranty period, accessories damaged by non-human factors will be replaced free of charge; outside the warranty period, accessories will be provided at cost price.

Related Products

Checkweigher for Food industry

Checkweigher for the pharmaceutical industry

Checkweigher for Cosmetics industry

Checkweigher for Daily Necessities

Checkweigher for Hardware fitting

Digital Metal Detection Machine

Checkweigher with metal detector

Hot Labels: intelligent,capsule,tablet,sample checkweigher,precise,weight control,manufacturer,supply,factory,price