Industrial Conveyor Checkweigher for Small Packages Space-Saving Check Weigher

This industrial conveyor checkweigher is designed to accurately check the weight of items in motion, ensuring product integrity without interrupting production. Its modular frame allows for easy integration into existing conveyor systems. Conveyor checkweigher for small packages has stainless steel construction withstands harsh industrial environments, and tool-free belt removal makes cleaning and maintenance quick and easy. For further information about our services, or if you would like one of our professionals to contact you, please do not hesitate to contact us.

Industrial conveyor checkweigher photos

Type SG-150U

Weighing Range 3-500g

Limited of product L: 100 W:150 H: 3-200mm

Accuracy ±0.1g Depends on product

Division Scale 0.1g

Belt Speed 0- 60 m/min

Max Speed 150 pcs/min

Belt Width 150mm

Machine Weight 60kg

Power Supply AC 220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

Industrial Conveyor Checkweigher for Small Packages Space-Saving Check Weigher

1. This industrial conveyor checkweigher uses a high-speed, low-noise, low-frequency motor and bearings as transmission components, reducing the risks of noise and interference.

2. To prevent electromagnetic and radiation hazards, this machine uses high-quality shielding materials to shield against various electromagnetic hazards and interference.

3. A high-definition touch screen is provided as a simple user interface.

4. The conveyor system consists of a brushless motor and conveyor belt. The brushless motor driver module provides high torque, high precision, and a wide speed range for the motor, ensuring uniform motion of the items and enabling the weighing unit to more accurately detect the item weight.

5. The industrial conveyor checkweigher consists of a main weighing unit and a vibrating weighing unit. The vibrating weighing unit is incorporated into the high-speed checkweigher to prevent external vibration. The vibrating weighing unit uses a high-precision, high-speed, and highly sensitive weighing sensor. The sensor converts the information of the item's forced rotation into an electrical signal, which is then communicated with the microcontroller and displayed on the touch screen.

1. Detect underweight and overweight packaging; detect missing accessories within the package, such as instructions, accessories, gifts, desiccants, and other accessories.

2. Full case inspection: Detect missing parts, packages, boxes, bottles, cans, and bags.

3. A USB data storage port allows report data to be transferred to a PC for analysis and printing. Parameter settings are password-protected, restricting access to management personnel only.

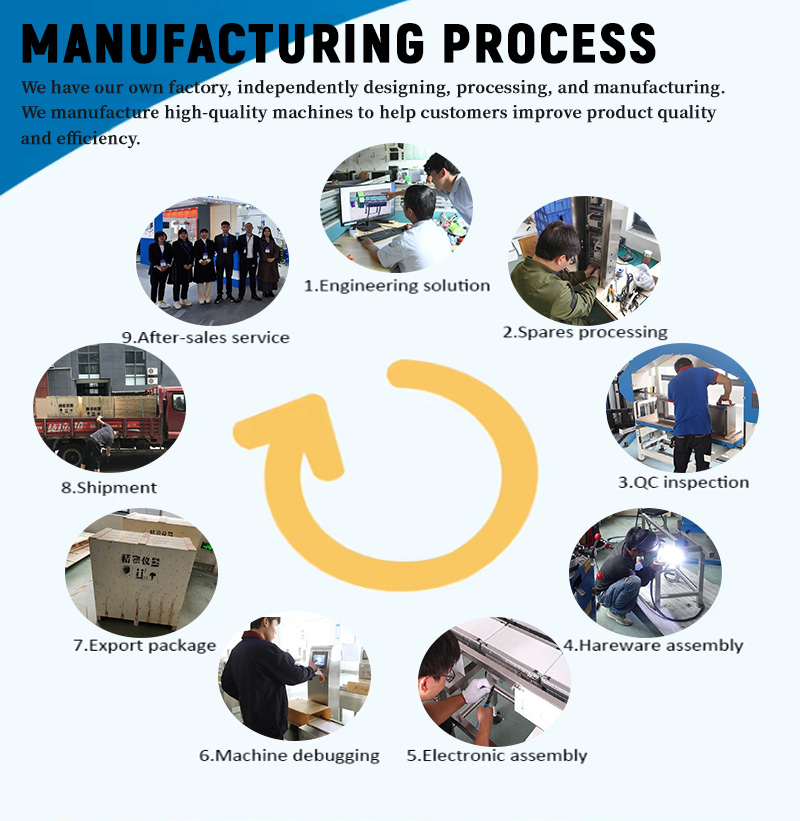

First step: The customer has presented their specific requirements.

Second step: We attempt to understand the customer's concept and pattern with a simple draft or reference image.

Third step: Creating a conceptual CAD drawing based on communication and understanding.

Fourth step: Creating a detailed 3D drawing to finalize the design and other details.

Fifth step: Quotation offer after confirming the design, material, and surface treatment.

Sixth step: Creating a sample for approval.

Seventh step: Testing and installation after a demo mock-up.

Eighth step: Full production delivery and service after sales.

Industrial Conveyor Checkweigher for Small Packages Space-Saving Check Weigher

Delivery Date: After receiving payment, delivery will be within 15-30 working days.

Packaging: Protective film + wooden case

Logistics: Air, sea, or express (DHL, etc.)

Freight: The cost of transport depends on the destination, mode of transport, and the weight of the goods.

Payment: T/T, Western Union, PayPal

1. Warranty: Our packaging machines come with a 12-month warranty. Most components (PLC, servo controller, servo motor, touch screen, cylinder) are covered by a free replacement warranty.

2. After-Sales Service: One-year warranty, lifetime repairs.

3. Technical Support: We provide technical consultation before placing an order, provide drawings and specifications, design custom solutions, and analyze and resolve technical issues.

4. Operation Training: We welcome your technical staff to visit our factory to learn about the operation process, take photos, and record videos.

Related Products

High-Speed Production Line Conveyor Checkweigher

Detergent Powder Multi-Lnae Packing Machine

Vertical Granular Powder Metal Detector

Industrial Checkweigher For Factories

Automatic Plastic Bottle Checkweigher

High Precision Tablet Inspection Checkweigher

Food-Grade Checkweigher for Packaged Snack

Automatic Tablet Metal Detector System

Hard Capsule Checkweigher with Real-Time Rejection

Samall Box Calcium Tablet Checkweigher

Hot Labels: industrial,conveyor,checkweigher,small packages,space-saving,check weigher,price,supplier,manufacturers,factory