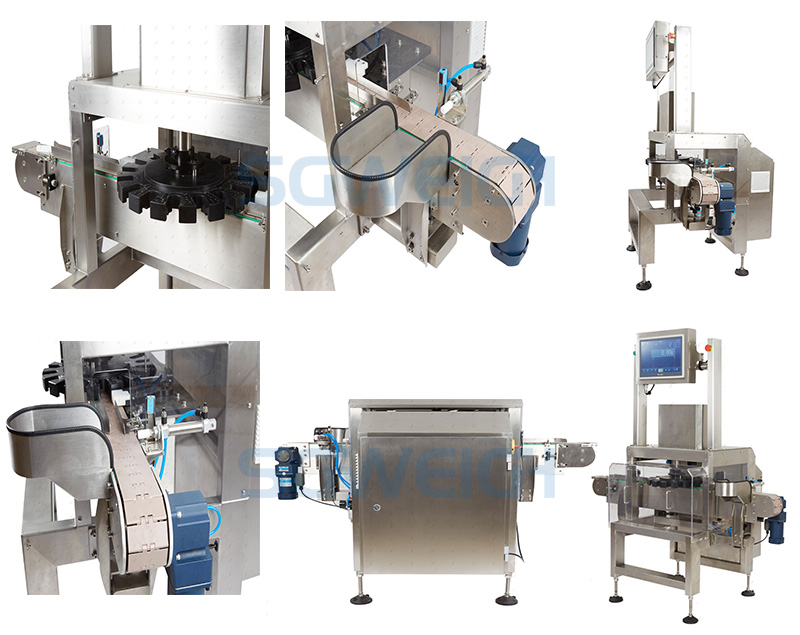

High Speed Turntable Checkweigher for Food Bottle Production Line Dynamic Rotary Check Weighing Machine

Automatic check weigher also called checkweigher, check weight machine, check weighing machine, weight checker, weight sorting machine, weighing scale, and etc,.

The rapid dynamic weighing algorithm software technology of the turntable checkweigher for food bottle enables the entire system to maintain high detection accuracy even during high-speed operation, and parameters can be modified at any time. The dynamic bottle rotary check weighing machine has a very user-friendly operating interface, ultra-high adaptability to equipment environments, and abundant peripheral resources, making it easy to connect with other devices. You are welcome to contact us at any time for further information.

Box check weigher for food industryi pctures

Model: SG-Z1

Weighing range: 5-300g

Minimum scale: 0.01g

Maximum sorting speed: 50 pieces/minute (one channel)

Conveying speed: 20-100m/min

Operation mode: Touch based operation

Transport direction: Facing the touch screen from left to right

Removal method: air blowing removal/push plate removal

Belt height: 750 ± 50mm (customizable according to customer requirements)

Machine structure: stainless steel (SUS304)

Power supply: 220V 50-60HZ

Power of approximately: 300W

Windshield thick acrylic (to avoid airflow interference)

Working environment temperature: 0 ℃~40 ℃, humidity: 30%~95%

The properties and usage environment of the tested product vary, and the detection speed and accuracy also vary. Actual testing is the standard.

1) Special design and optional configuration can ensure long-term operational stability;

2) A single sensor is not limited by the area of the weighing platform, and can achieve high-speed and high-precision detection requirements;

3) The installed communication module can upload data in real time and effectively monitor it;

4) The large range of measurement facilitates the detection of objects of all sizes in the logistics industry;

5) 7-inch or 10 inch color high-definition touch screen, information is clear at a glance;

6) A professional operating system with rich features and simple operation

1st step: Customer has showed his special requirements.

2nd step: We try to understand the conception and pattern from customer with simple draft or refer picture.

3rd step: Making the conceptive CAD drawing based on communication and understanding.

4th step: Making the detail and 3D drawing agter fixed the design and other details.

5th step: Offer the quotation after confirm the design,material and surface treament.

6th step: Making the sample for approval.

7th step: Testing installation after demo mock up.

8th step: Big production delivery and service after sales.

The turntable checkweigher for food bottle can be widely used for weight testing after packaging in multiple fields such as food, pharmaceuticals, chemicals, textiles, clothing, toys, rubber, etc.

Shanghai Shigan Industrial Co., Ltd., products' are designed, engineered, and manufactured by highly skilled and experienced engineers to produce high-quality, precise, intelligent, and affordable product control systems and safety inspections. For over 15 years, we have been providing customized machines to our customers to meet their quality control and safety needs. Our reputation for CE certified products is based on consistent quality and advanced technology, which is the result of continuous in-depth research and development. Strict quality standards ensure that we meet customer requirements every time. We are proud of our products and services. We are committed to ensuring quality control and safety inspections by providing the best value to all customers worldwide.

Our main products:

Capsule and Tablet Checkweigher

Checkweigher and Labeling Machine Combo

Checkweigher and Metal Detector Combo

The usual packaging is a wooden box (size: length * width * height). If exported to European countries, wooden boxes will undergo fumigation treatment. If the container is too tight, we will use polyethylene film packaging or packaging according to the customer's special requirements

In order to find the best solution, save costs, provide the best service, and earn more profits for our partners, we look forward to long-term cooperation!

Pre sale.

1. Project design, performance introduction, technical agreement, contract signing, packaging

2. Inquiry and consultation support.

3. Sample testing support.

In terms of sales.

We will provide you with the latest developments in product assembly, packaging, and transportation.

After sales service.

1. We will provide free accessories for non human component damage.

2. Training on how to install the machine, video training on how to use the machine, etc

3. One year warranty and lifelong maintenance

About after-sales service, we promise:

The products sold to customers in one year, non-human or external causes of quality problems caused by the implementation of free maintenance and lifetime sales.

Customers purchase the product, if there is a problem in the installation of technology, our company will cooperate fully solve the problem.

Division I is a regular company, operating integrity, many customers receive the praise.

Related Products

Industrial Box Carton Conveyor Belt Checkweigher

Multifunctional Capsule Tablet Metal Detector

Small Seasoning Package Food Multi-lane Checkweigher

High Speed Jar Can Food Checkweigher

Checkweigher for Pharmaceutical Pouchs Bags Sachets

Multi functional Pharmaceutical Automatic Metal Detector

Hot Labels: high speed,turntable,checkweigher,food,bottle,production line,dynamic,rotary,check weighing machine,price,supply,factory,manufacturer