High-Performance Rotary Checkweigher for Small Bottles Turntable Check Weigher

Checkweigher as known as check weigher, check weight machine, check weighing machine, weight checker, weight sorting machine, and etc,.

The rotary checkweigher for small bottles combines advanced load cell technology with a rotating turntable to provide real-time weight detection while maintaining full throughput, with each unit individually weighed and sorted within milliseconds. Designed for continuous motion packaging lines, the high-performance turntable check weigher delivers unmatched speed and precision for round or unstable products such as bottles, vials, cans, or jars. To know more about us, please you do not hesitate to contact us or visit our factory.

Rotary checkweigher for small bottles photos

This rotary checkweigher for small bottles has a flexible design and is compatible with bottles of various small sizes, shapes and materials. It is widely used in electronics, food, medicine, beverage, health care, chemical and other industries.

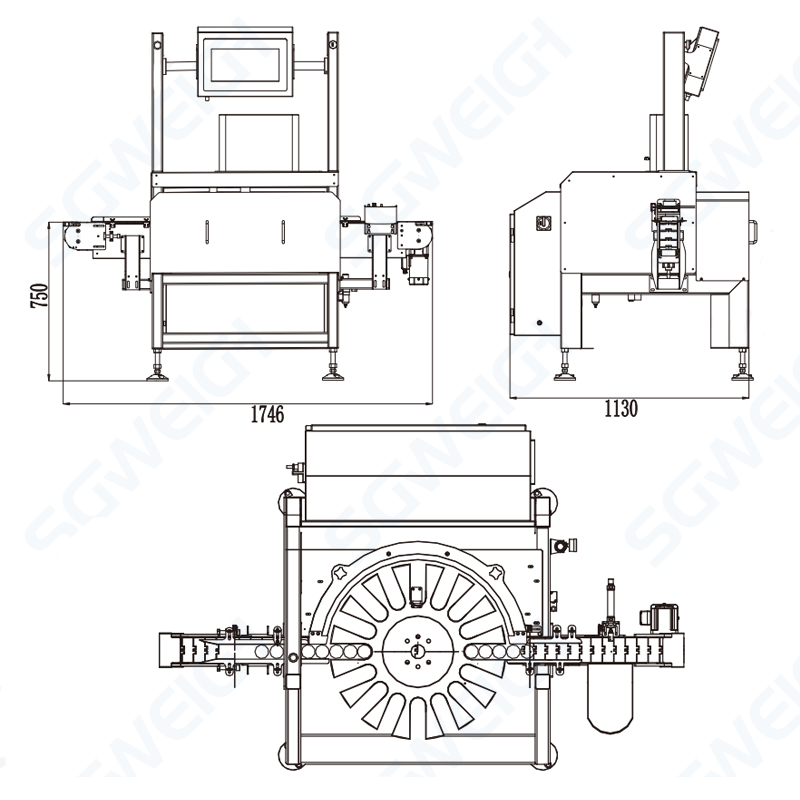

Type SG-Z

Weighing Range 2-300

Restrictions of Products:φ10-100 H:20-200mm

Limited of product L: 180 W: 40 H: 2-20mm

Accuracy ±0.01g Depends on product

Division Scale 0.01g

Belt Speed 0- 50 m/min

Max Speed 60 pcs/min,120 pcs/min,180 pcs/min(optinal)

Belt Width 100mm

Machine Weight 260kg

Power Supply AC 110/220V ±10% 50HZ

Power 400W

Main Material SU304 stainless steel

High-Performance Rotary Checkweigher for Small Bottles Turntable Check Weigher

1. Large-size color LCD touch screen interface, simple operation and intuitive display.

2. Supports customized multi-language, default is Chinese and English.

3. With photoelectric automatic detection of empty packages, the conveyor belt speed is adjustable.

4. Parameter setting three-level password protection, only management personnel can operate.

5. Product weighing data can be exported via USB.

6. Power-off protection function, the parameters remain unchanged in case of accidental power off.

7. The parameters of different products can be set to store 100 types of test data, which is convenient for users to switch and call.

8. Data statistics function. The total number of products passing/total number of underweight products/total number of overweight products in a period of time.

9. Simple mechanical structure, buckle conveyor belt, easy to disassemble, clean and maintain. Comply with GMP and HACCP specifications.

10. Automatic dynamic compensation value, dynamic zero point tracking, including zero point tracking when the equipment is running continuously, to ensure reliable test data.

11. The curve graph/bar graph shows the statistical distribution of the sorting (re-testing) results, and the window shows the values of the last 10 re-testing results.

12. The patented technology, the single-chip system independently developed, and the unique filtering algorithm have ultra-high accuracy and reliability. Ensure system stability.

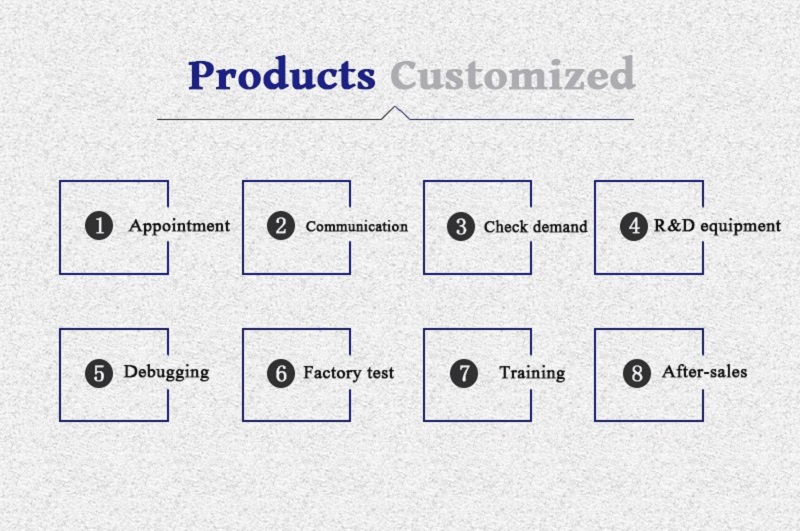

Shanghai Shigan provides users in various industries with rotary checkweigher for small bottles application customization services, from selection, solutions, design, front-end and back-end connection auxiliary agencies to training services, aiming to meet users' personalized needs, improve production efficiency, and ensure product quality.

High-Performance Rotary Checkweigher for Small Bottles Turntable Check Weigher

Machine packaging:

Export standard non-fumigation wooden box, in line with customs clearance requirements

Delivery cycle:

10-15 days after receiving payment

Price terms:

FOB terms, CIF/CFR terms (sea/air), DDU/DDP terms (sea or air)

Transferable payment methods: T/T, LC, D/P, D/A. , etc.

1. Pre-sales consultation

We will help you customize the appropriate weighing and packaging solutions according to your requirements and specific circumstances.

2. Installation service

We will dispatch professional technicians to carry out on-site installation and commissioning as needed.

3. Maintenance service

Shigan provides long-term maintenance services, providing any repair parts free of charge during the warranty period, and only charges after the warranty period expires.

4. Staff training

Shigan provides free technical training for our customers to fully master the correct product maintenance technology.

5. Customer service

Shigan designs customized production lines for customers based on specific weighing and packaging factors such as product output, packaging method and factory area.

Related Products

Auto Protein Powder Multi-Row Packing Machine

Precision Tablet Sampling Checkweigher

Space-Saving Metal Detector Checkweigher Combo

Real-Time Tube Weight Checker for Ointments & Creams

Powder Granule Metal Detector for High-Purity Lines

High-Speed Checkweigher for Narrow Sachet Pouch

Dynamic Carton Inspection Checkweigher Solution

Inline Metal Detection System for Pharma Bottles

Multi-Lane Granule Packaging Machine Customizable

Ultra-High Speed Box Check Weigher

Hot Labels: high-performance,rotary checkweigher,small bottles,turntable check weigher,supplier,factory,manuafcturer,price