Conveyor Belt Industrial Checkweigher Automatic Bag Checkweighing Solution

Industrial conveyor belt checkweighers are equipped with advanced load cell technology and intelligent control software to ensure that each unit meets precise weight specifications to avoid underfilling or overfilling. Automatic bag checkweighing solutions are flexible weighing solutions for a variety of bag types, and their durable stainless steel construction and high-load capacity sensors enable reliable operation in high-throughput production lines. You are welcome to contact us at any time for quotation.

Industrial conveyor belt checkweigher pictures

1. Online weighing of products in dynamic operation can be realized

2. Dynamic weighing detection can be performed according to preset weight requirements

3. The weight of each product can be 100% automatically detected

4. Standardized weight detection and troubleshooting can be performed according to the speed of the assembly line. Product inspection weight parameters

5. Automatically remove products with unqualified weight or perform quality classification

Industrial conveyor belt checkweigher is widely used in

1. Leisure food: various packaging such as potato chips, biscuits, jellies, sweets, tea bags, instant noodles, etc.

2. Agricultural products: rice bags, dried fruit net bags, grains, frozen products

3. Daily cosmetics: bottled shampoo, cosmetic bags, filling aerosols

4. Hardware industry products: printing, toys, PCB boards, metal parts

5. Pharmaceutical industry: bottle pills, small particle sachets, pulse bottles, etc.

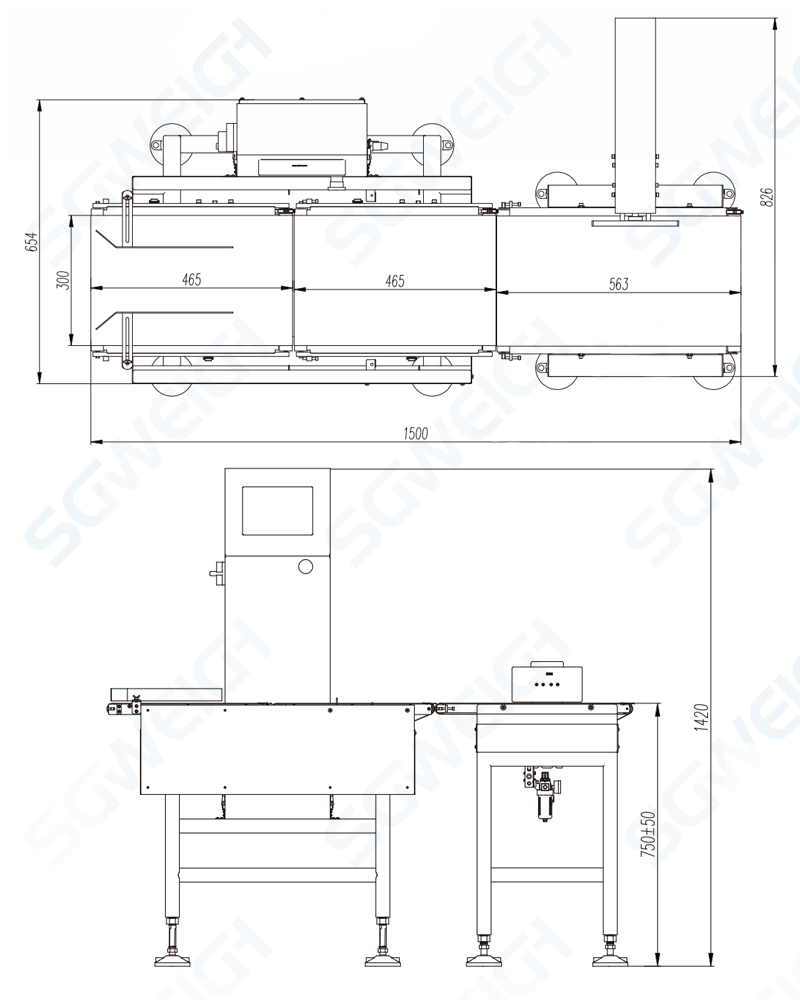

Type SG-300U

Weighing Range 5-3000g

Limited of product L: 350 W:300 H: up3mm

Accuracy ±0.3g-0.5g Depends on product

Division Scale 0.1g

Belt Speed 0- 60 m/min

Max Speed 80 pcs/min

Belt Width 300mm

Machine Weight 85kg

Power Supply AC -220V 50HZ

Power 200W

Main Material SU304 stainless steel

Conveyor Belt Industrial Checkweigher Automatic Bag Checkweighing Solution

According to the customer's needs and specific scenarios, we provide a wide range of customization options, such as: conveyor configuration, rejection mechanism, weighing capacity, software functions, user interface and integrated functions to meet the customer's personalized needs in terms of function, performance, appearance, etc.

Conveyor Belt Industrial Checkweigher Automatic Bag Checkweighing Solution

Machine packing :

Non-fumigation wooden case for export standard and comply with customs clearance requirement

Lead time :

10-15 days after payment received

Price term :

FOB term, CIF/CFR term(sea/air), DDU/DDP term( sea/air)

Negotiable payment term: T/T , LC, D/P ,D/A .,etc

1. Equipment installation and commissioning: The company provides a detailed operation manual and free operation training to ensure that customers can use the equipment proficiently.

2. Technical support: The company provides 24-hour technical support to help customers solve problems encountered during use.

3. Accessories supply: The company provides original accessories to ensure the quality and stability of accessories.

4. Quality assurance: The company is responsible for the products sold and ensures that the quality and performance of the equipment meet industry standards.

5. Warranty policy: One-year warranty and lifetime maintenance to solve worries for customers.

Related Products

Carton Conveyor Checkweigher Weight Checker

Online Seasoning Bag Metal Detector

Peanut Sauce High-Speed Multi-Row Packing Machine

Bottle Tuna Checkweigher With Rejection

Online Turntable Checkweigher For Bottle

Dynamic Bag Box Packaging Checkweigher

Aluminum Foil Sachet Metal Detector For Food

Multiline Checkweigher For Separate Stickpack Pouches

High-Precision Tablet Metal Detector For Pharma

Tablet Online Left Right Sorting Checkweigher

Hot Labels: conveyor,belt,industrial checkweigher,automatic,bag,checkweighing,solution,supplier,manufacturer,price