Capsule Tablet Metal Detector for Pharmaceutical Safety Throat Metal Detector

This capsule tablet metal detector for pharmaceutical safety is designed to ensure pharmaceutical safety, exhibiting extremely high sensitivity to ferrous, non-ferrous, and stainless steel contaminants. Even minute metal particles can be accurately detected before product packaging, protecting patients and ensuring product integrity. Designed for seamless integration, this capsule tablet throat metal detector allows for high-speed, continuous operation without impacting production efficiency. Intelligent signal processing technology minimizes the impact on the product while maintaining consistent detection accuracy. You are welcome to contact us at any time for quotation.

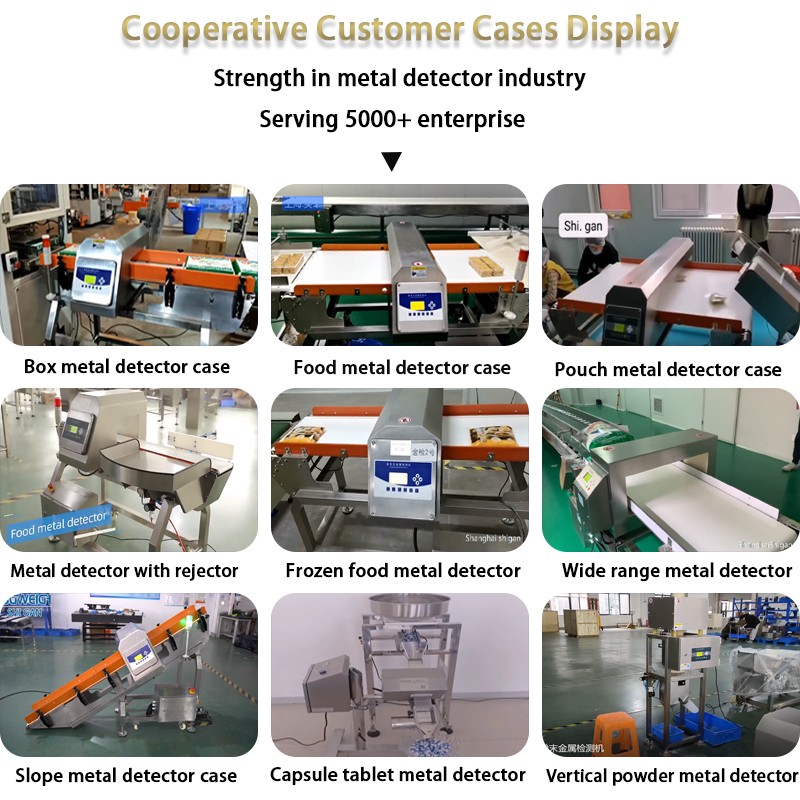

Capsule tablet metal detector for pharmaceutical safety photos

Type: SG-M50

Feed port height and size: Height: 770-930mm Feed port size: 76mm

Height and size of outlet: Height: 770-860mm Size of outlet: 51mm

Effective passing size: W70*H20mm

Maximum production capacity: 500,000 pcs/hour

Detection sensitivity: Fe: 0.4mm, stainless steel: 0.6mm

Machine weight: 75kg

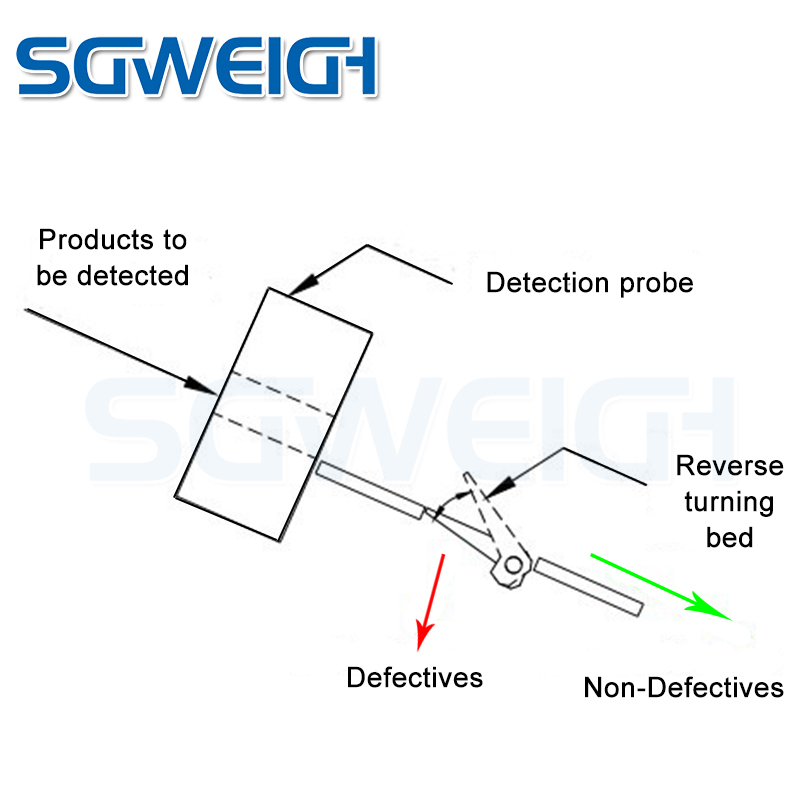

Removal method: flip culling

Working voltage: 220V/110V, 50/60HZ

Equipment dimensions: 1115*550 (1280-1400) mm

Capsule Tablet Metal Detector for Pharmaceutical Safety Throat Metal Detector

1. Ultra-precise detection of ferrous, non-ferrous, and stainless steel contaminants, with a rapid rejection mechanism to ensure uninterrupted production.

2. High-throughput performance and a rapid, automatic rejection system to meet the demands of demanding production lines.

3. User-friendly digital control and real-time monitoring.

4. Seamless integration into tablet presses, capsule filling machines, and downstream conveyors.

5. Durable stainless steel construction ensures long-term reliability.

6. Designed specifically to ensure pharmaceutical safety, meeting pharmaceutical manufacturing standards and ensuring product integrity from start to finish.

This capsule tablet metal detector for pharmaceutical safety ensures reliable detection of coated, uncoated, hard, or soft capsules.

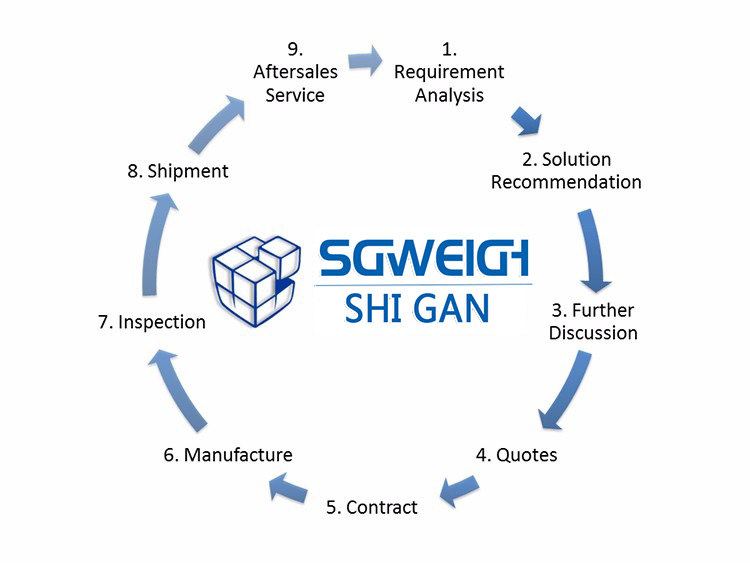

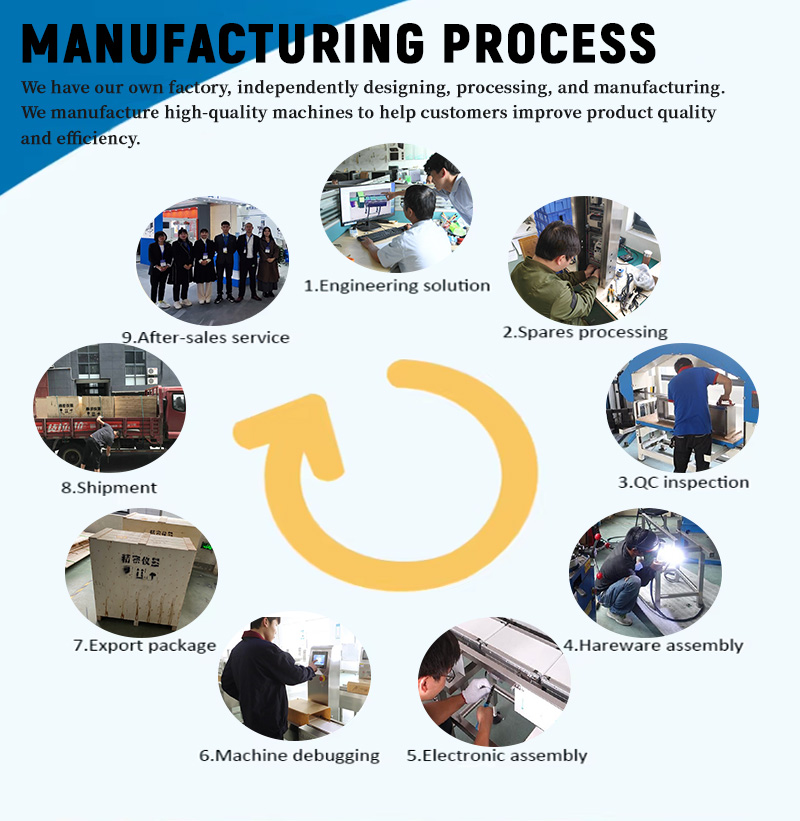

SGWEIGH can tailor a capsule tablet metal detector for pharmaceutical to meet the specific needs and usage scenarios of its clients, satisfying their individual requirements in terms of functionality, performance, and appearance.

Capsule Tablet Metal Detector for Pharmaceutical Safety Throat Metal Detector

Machine Packing: Non-fumigation wooden case for export standard and comply with customs clearance requirements.

Lead Time: 10-15 days after payment received.

Price Term: FOB, CIF/CFR (sea/air), DDU/DDP (sea/air).

Negotiable Payment Terms: T/T, LC, D/P, D/A, etc.

1. Customer Consultation and Technical Support: Providing customers with consultation services regarding product use, repair, and maintenance, and answering questions encountered during operation and use.

2. Technical Training: Providing training tailored to customer needs on product operation, maintenance, and repair, ensuring customers can correctly use and maintain the products.

3. Parts Supply: Providing genuine parts, ensuring the quality and performance of parts to meet user needs.

4. One-Year Warranty, Lifetime Repair

5. After-Sales Service Tracking: Tracking and providing feedback on the after-sales service process, promptly understanding customer needs and opinions, and continuously improving service quality.

ReLated Products

Multi-Lane Packing Machines for Physiological Saline

Automatic Cup Food Weight Sorting Checkweigher

High-Speed Checkweighing Solutions for Box Packaging

Digital Metal Detector for Chemical Processing

Large-Range Food Metal Detector Conveyor

High-Speed Inspection 4-Lines Checkweigher

Online Bottle Checkweigher with Clamping Conveying

Mini All-Rounds Sample Checkweigher for Capsule Tablet

Multi-lane Three Side Sealing Granule Packaging Machine

High Speed Automatic Feeding Checkweigher for Bottle

Hot Labels: capsule tablet metal detector,pharmaceutical,safety,throat metal detector,manufacturers,supplier,factory,price