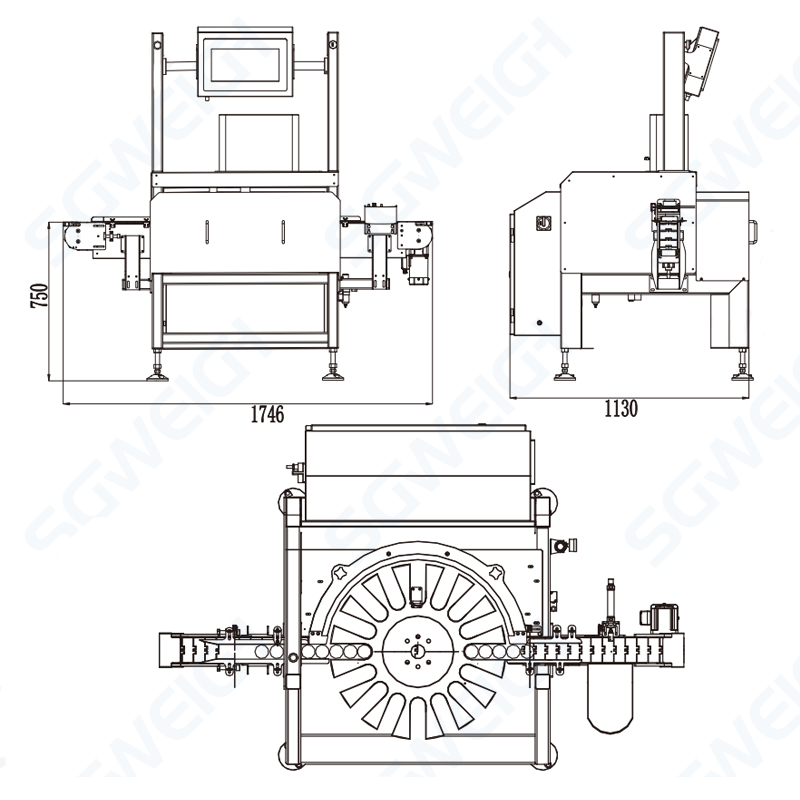

Bottle Production Line Weight Checking Machine Rotary Weighing Checkweigher

Checkweigher as known as check weigher, check weight machine, check weighing machine, weight checker, weight sorting machine, and etc,.

A bottle production line weight checking machine is an automated quality control device used in packaging lines to ensure that each bottle contains the correct amount of product. It works by dynamically weighing each bottle as it moves along the line and automatically rejecting any bottles that are overweight or underweight based on preset tolerances. By incorporating bottle rotary weighing checkweighers into your production line, the quality of your product can be improved without sacrificing efficiency. To know more about us, please you do not hesitate to contact us or visit our factory.

Bottle production line weight checking machine photos

Type SG-Z

Weighing Range 2-300

Restrictions of Products:φ10-100 H:20-200mm

Limited of product L: 180 W: 40 H: 2-20mm

Accuracy ±0.01g Depends on product

Division Scale 0.01g

Belt Speed 0- 50 m/min

Max Speed 60 pcs/min,120 pcs/min,180 pcs/min(optinal)

Belt Width 100mm

Machine Weight 260kg

Power Supply AC 110/220V ±10% 50HZ

Power 400W

Main Material SU304 stainless steel

Bottle Production Line Weight Checking Machine Rotary Weighing Checkweigher

Our professional engineers will design the most suitable bottle rotary weighing checkweigher solution for your production line to meet the different needs of various complex production lines. In actual applications, we will also continuously optimize and improve the bottle rotary weighing checkweigher solution based on the operating status of the production line and customer feedback to ensure that it is always in the best working condition.

1. Automatic sorting - automatic sorting method, convenient and fast;

2. Adjustable speed - high-precision detection, adjustable conveying speed;

3. Parameter setting - upper and lower weight limit parameters can be set arbitrarily;

4. Variable frequency speed regulation - the conveying system adopts variable frequency speed regulation mode, which is convenient for speed regulation;

5. Data storage - powerful data statistics function, recording daily detection data;

6. Data call - with set data group memory, call function, easy operation;

7. Data recording - OK number, underweight number, overweight number are accumulated separately;

8. Fault diagnosis - self-fault diagnosis and prompt function, convenient maintenance;

9. Multi-group storage - can store 100 groups of set parameters for storage;

10. Processing method - unqualified product alarm/shutdown, rejection is optional;

11. Data viewing - historical record query function, can be expo

Bottle rotary weighing checkweighers are widely used in food, beverage, pharmaceutical, sanitary products, washing products, daily chemicals, chemical and other industries. Bottled weighing scales are currently reliable and important intelligent inspection equipment for automatic weighing inspection or quality inspection and troubleshooting of assembly lines.

Bottle Production Line Weight Checking Machine Rotary Weighing Checkweigher

1. Inner packing is plastic film, outer is wooden or plywood box

2. Only bare packing with plastic film with plastic pallet.

3. We can provide fumigation packing and certificates.

4. Shipping, training, express or as per customer requirements.

5. Port: Shanghai

1. Pre-sales consultation

We will help you customize the right weighing and packaging solution according to your requirements and specific circumstances.

2. Installation service

We will dispatch professional technicians for on-site installation and commissioning as needed.

3. Maintenance service

Shigan provides long-term maintenance service, and any maintenance parts are provided free of charge during the warranty period, and only charged after the warranty expires.

4. Staff training

Shigan provides free technical training for our customers to fully master the correct product maintenance technology.

5. Customer service

Shigan designs customized production lines for customers based on specific weighing and packaging factors such as product output, packaging method and factory area.

Related Products

High Sensitivity Pharmaceutical Metal Detector

Online Capsule Tablet Checkweigher

Aluminium Foil Stick Sachet Multi-lane Packing Machine

Small Box Sachet Mini Checkweigher

High Performance Capsule Tablet Sampling Checkweigher

Automatic Balance Grade Check Weigher For Packing Line

Checkweigher And Metal Detector Combination

Pharmaceutical Metal Detector for Capsule Tablet

Food Checkweigher For Plasic Bottle

Large Carton Box Checkweigher Machine for Industrial

Hot Labels: bottle,production line,weight checking machine,rtotary weighing,checkweigher,supplier,factory,manuafcturer,price