Aluminum Foil Packing Weight Checker With Metal Detector Combo System

The weight checker with metal detector combo system is a powerful solution for manufacturers seeking to ensure weight accuracy and product safety in one integrated system. The aluminum foil packing weighing metal detector machine integrates the metal detector and the checkweigher, greatly improving the safety and reliability of production, simplifying the production process, saving space, reducing costs, and ensuring that the product meets quality and safety standards. You are welcome to contact us at any time for quotation.

Dynamic checkweigher and metal detector combo pictures

Aluminum Foil Packing Weight Checker With Metal Detector Combo System

Customized support: OEM, ODM

Place of Origin: China

Brand Name: SHIGAN

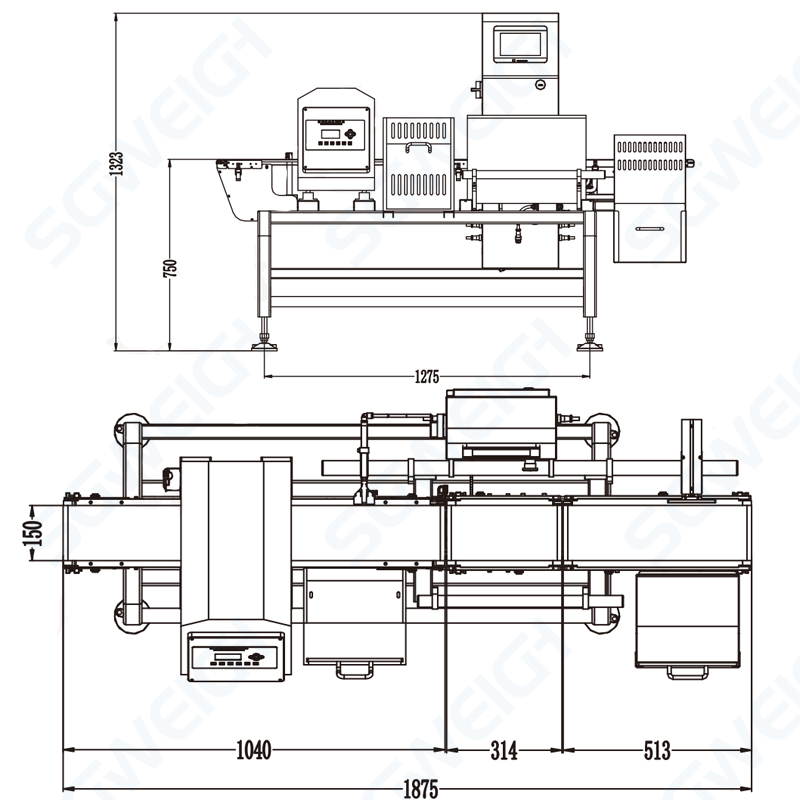

Rated power: 0.4KW

Single weighing range: ≤40KG

Accuracy: ±5G~±30G

Conveying speed: 20~35m/Minute

Belt size: 1200mm(L)600mm(W)

Product size: 1888mm(L)*935mm(W)*1060mm(H)

Removal method:Push-rod

Fuselage material: 304 Stainless Steel

Working temp: 0°~40°&30%~95%

1. The weight checker with metal detector combo system have a small footprint and good metal free area characteristics, which shortens the length of the combined equipment and minimizes the space requirements of the production line. The weight checker with metal detector combo system functions are integrated on a simple cantilever frame, which can be easily and effectively installed in the existing workshop, thus minimizing the installation cost. High-speed digital signal processing devices and intelligent algorithms improve detection accuracy and stability. The cantilever structure is adopted, mainly made of stainless steel. It uses FDA-approved plastic conveyor base, which greatly improves the hygiene and flushing quality of the equipment.

2. The advanced weighing controller in the device enables users to improve their processing efficiency and profitability. Production line operators

3. Can understand the performance of the production line at any time from the statistical information graphic display and make necessary adjustments to ensure the highest efficiency of the production line.

4. The automatic servo feedback controller of the feeder ensures the highest efficiency of the feeding process.

5. LCD liquid crystal display, Chinese and English menu screen, easy to realize human-computer dialogue operation.

6. A variety of feedback options to meet the needs of various feeding operations.

7. With memory function, it can expand the storage of detection parameters of multiple products.

8. Simple detachable frame, convenient for users to clean.

9. Provide multi-language support menu.

10. Special design of the conveyor belt to prevent the conveyor belt from deviation.

11. The use of high-performance sensors and integrated motors further improves performance.

12. Provide scrap inspection function to ensure reliable operation, and can be operated in qualified product flow or scrap flow.

13. Continuous scrap alarm indicates that "n" scraps appear continuously.

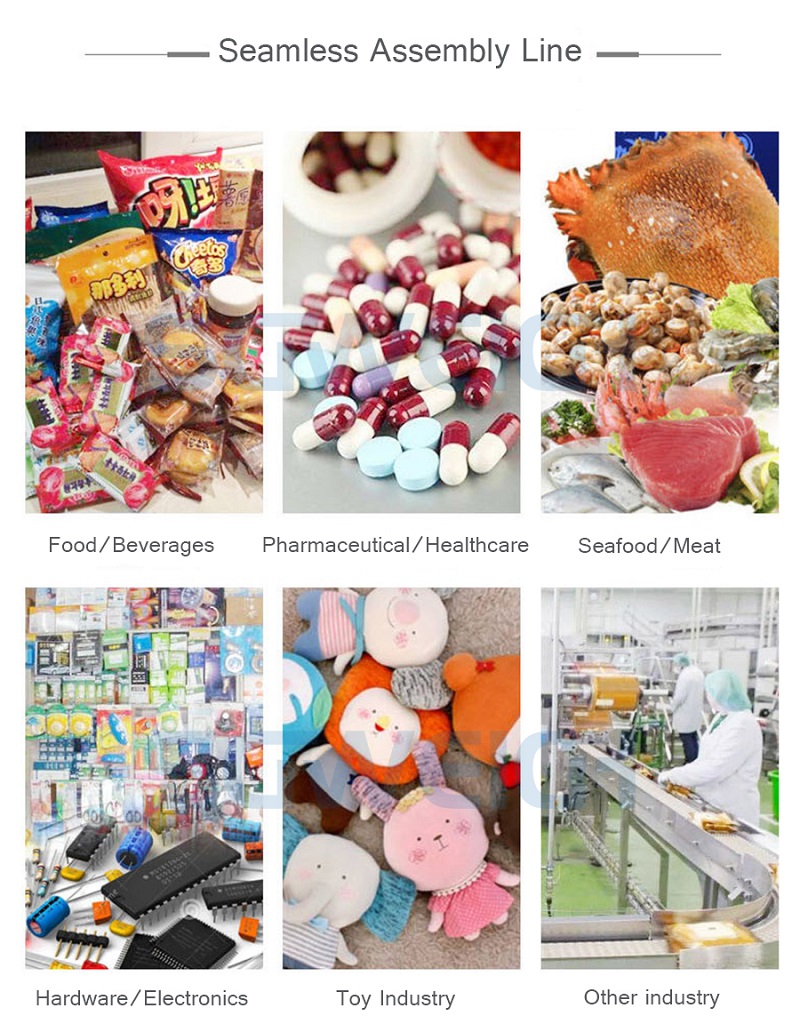

Weight checker with metal detector combo systems are widely used in many industries such as electronic hardware, pharmaceuticals, food, chemicals, beverages, health products, etc. Bags, sachets, boxes, jars, cans, cartons and other packaged products are weighted and metal detected.

Our professional engineers will design the most suitable weight checker with metal detector combo system solution for your production line to meet the different needs of various complex production lines. In actual applications, we will also continuously optimize and improve the weight checker with metal detector combo system solution based on the operating conditions of the production line and customer feedback to ensure that it is always in the best working condition.

Aluminum Foil Packing Weight Checker With Metal Detector Combo System

Packaging:

1. Outer packaging: standard export wooden boxes

2. Inner packaging: carefully stretch film is used to wrap the product, and hardwood boards + strong bandages are used to fix the corners.

3. Inspection team: Professional personnel will inspect and classify your goods.

1. Equipment installation and commissioning: The company provides a detailed operation manual and free operation training to ensure that customers can use the equipment proficiently.

2. Technical support: The company provides 24-hour technical support to help customers solve problems encountered during use.

3. Accessories supply: The company provides original accessories to ensure the quality and stability of accessories.

4. Quality assurance: The company is responsible for the products sold and ensures that the quality and performance of the equipment meet industry standards.

5. Warranty policy: One-year warranty and lifetime maintenance to solve worries for customers.

Related Products

Miniature Check Weigher with Counting Function

50g Suger Sachet Multi-Lane Checkweigher

Long Strip High-Speed Multi-Row Granule Packaging Machine

Online Pouch Weighing Sorting Checkweigher Machine

Medicine Packaging Box Checkweigher

Agricultural Product Weight Sorting Machine

Capsule High-Precision Checkweigher for Large Quantities

Metal Detector Combination Check Weigher for Bag Carton

Thick Juice Sachet Compact Multi-Lane Packing Machine

High Precision & Speed Checkweigher

Hot Labels: aluminum foil packing,weight checker with metal detector combo,system,factory,price,supplier,manufacturer