5g 10g 15g Dry Powder Filling Packing Machine With Auger Filler Multi-Function Packaging Machine

The auto packing machine is fully controlled by computer touch screen, man-machine interface, simple and convenient operation, simple and convenient replacement of products, fault display system, convenient and fast maintenance. The powder packing machine with auger filler adopts the screw head to fill the material, which is especially suitable for the powder with poor fluidity, with high measurement accuracy and fast speed.Any OEM and customer design orders are welcome! If you are interested in our products, please feel free to contact us.

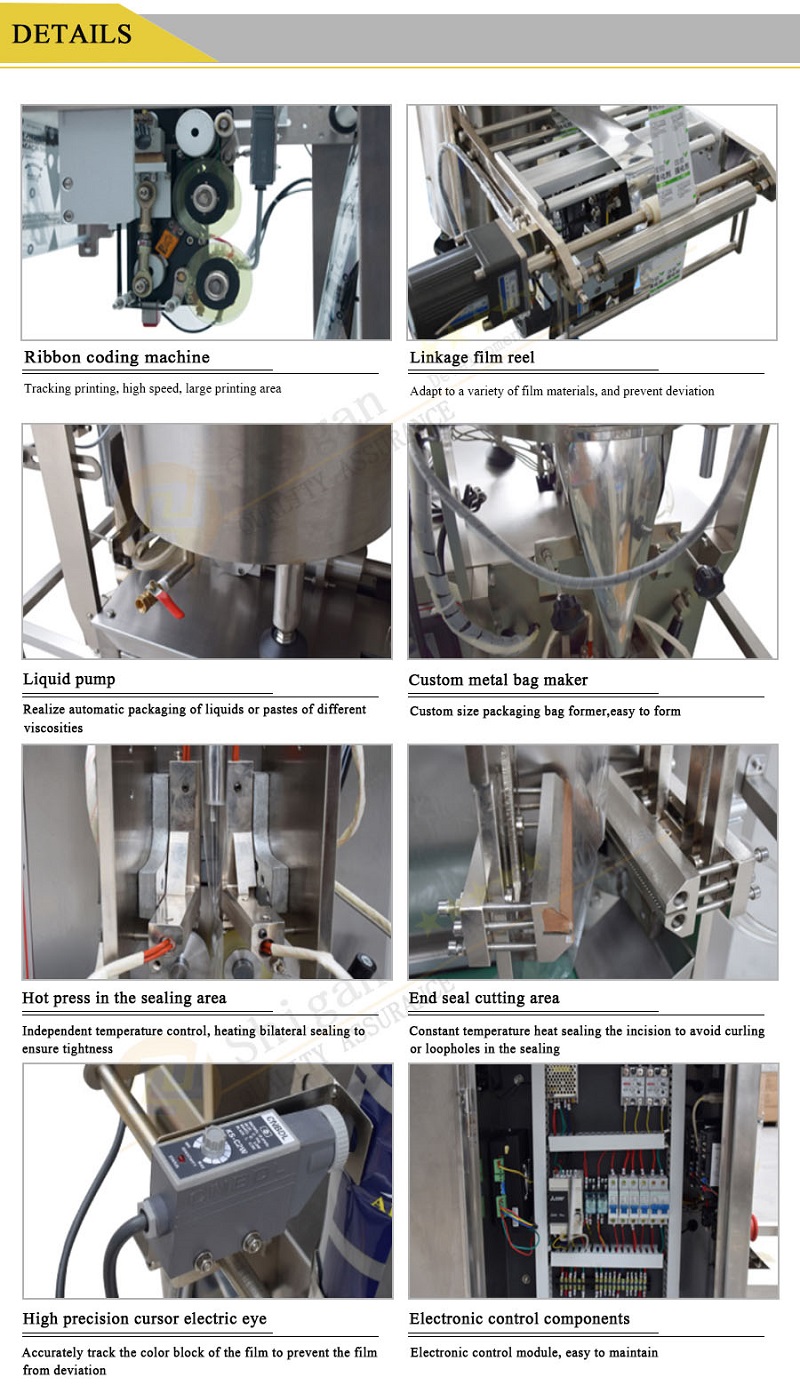

Powder Filling Packing Machine With Auger Filler pictures

1. The packaging machine implements self-automatic detection, information feedback and other functions. If there is no packaging bag or the packaging bag is not opened during the production operation, the detection device controls not to fill or seal, the running status is displayed in real time, and the machine stops automatically. Saving packaging materials and raw materials, ensuring the packaging site environment and raw material pollution.

2. Spiral metering device: The powder screw filling device is an independent metering and filling system. The device is driven by a high-precision stepping motor, and the screw is filled. Within the measuring range of the machine, several different sizes of screws can be used to complete different measuring ranges. Simple, convenient and precise operation.

3. Screw feeder: Filling motor-driven screw has the advantages of accurate positioning, high precision, fast speed, large torque, long life, adjustable speed, good stability, etc. Replacement of screw accessories can adapt to ultra-fine powder to large Particles and other materials.

4. Quickly change the specifications of packaging bags: The easy and quick debugging of the manipulator device overcomes the disadvantage of changing the weight due to the change of the specific gravity of the material.

5. Frequency conversion speed regulation, the machine uses frequency conversion speed regulation device, the packaging weight can be adjusted steplessly at any time, the working state can be changed at any time, and the operation is convenient.

6. The packaging machine can make a variety of bag types, such as: three-dimensional bags, flat bags, handbags, zipper bags, four-side sealing bags, three-side sealing bags, paper bags, M-shaped bags and other prefabricated bags made of composite bag films.

7. Horizontal bag delivery method: The bag storage product can store more packaging bags, the quality requirements of the bags are low, and the rate of bag separation and bagging is high.

8. Dust does not leak out, filling the outlet vacuuming device to protect the workshop environment.

9. Finished product conveying: stable work, anti-interference, high weighing accuracy, convenient and intuitive operation.

The main purpose of auto packing machine: pesticides, fertilizers, veterinary drugs, feed, premixes, additives, washing powder, salt, monosodium glutamate, chicken essence, sugar, seeds, rice and other granular and powdery materials can be quantitatively packaged.

Powder Spiral Dosing Machine

one. This set of hosts

Necessary: ①Host ②Spiral metering machine

Optional: ③Screw feeder ④Finished product conveyor

Different specifications of the screw machine can be combined with the automatic vertical packaging machine, especially suitable for the measurement and packaging of ultra-fine powder materials, integrating measurement, bag making, packaging, sealing, printing and counting.

Packing speed: 30~80 packs/min

Measuring range: 20~500g 200~1000g

Bag size: (50-290) × (60-200) mm (L × W)

Inner diameter of roll paper core: Ф75 mm

Outer diameter of packaging material: ¢400

Inner diameter of roll paper core: ¢75

Power supply: 3 kW 220V±10% 50 Hz

In the spirit of pursuing high-quality products and customer satisfaction, Shanghai Henggang Company solemnly promises you the principle of preferential price, thoughtful service and reliable product quality.

1. Product quality commitment:

(1). There are quality records and testing data for the manufacture and testing of products.

(2). For the inspection of product performance, we sincerely invite users to inspect the whole process and performance of the product in person. After the product is confirmed to be qualified, it will be packaged and shipped.

2. the product price commitment:

(1). Under the same competitive conditions, our company will sincerely provide you with a preferential price on the basis of not reducing the technical performance of the product or changing the product components.

3. Delivery time commitment:

(1). Product delivery time: as far as possible according to user requirements, if there are special requirements, it needs to be completed in advance, and strive to meet user needs.

Related Products

High Quality Linear Weigher Auto Packing Machine

High Capacity Granule Pneumatic Packing Machine

Weight Checker Machine For Production Line

2-50 g Automatic Small Vertical Packaging Machine

Milk Water Packaging Machine Small Bag

Multi-head Weigher Packing Machine Z-type Elevator

Hot Labels:powder,filling,packing machine,auger filler,multi-function packaging machine