4-Side Sealing Vertical Saline Packing Machine Automatic Small Bag Liquid Packaging Machine Factory

The fully automatic liquid packing machine uses a stable cam mechanical transmission technology to stabilize the equipment operation, low failure rate, and low energy consumption. At the same time, the small vertical packaging machine adopts advanced technologies such as circuit structure, human -machine interface (PLC+HMI), to achieve electromechanical integration, and it is easy to operate.Our product specifications and sizes are rich, various styles, welcome to contact us for quotation information.

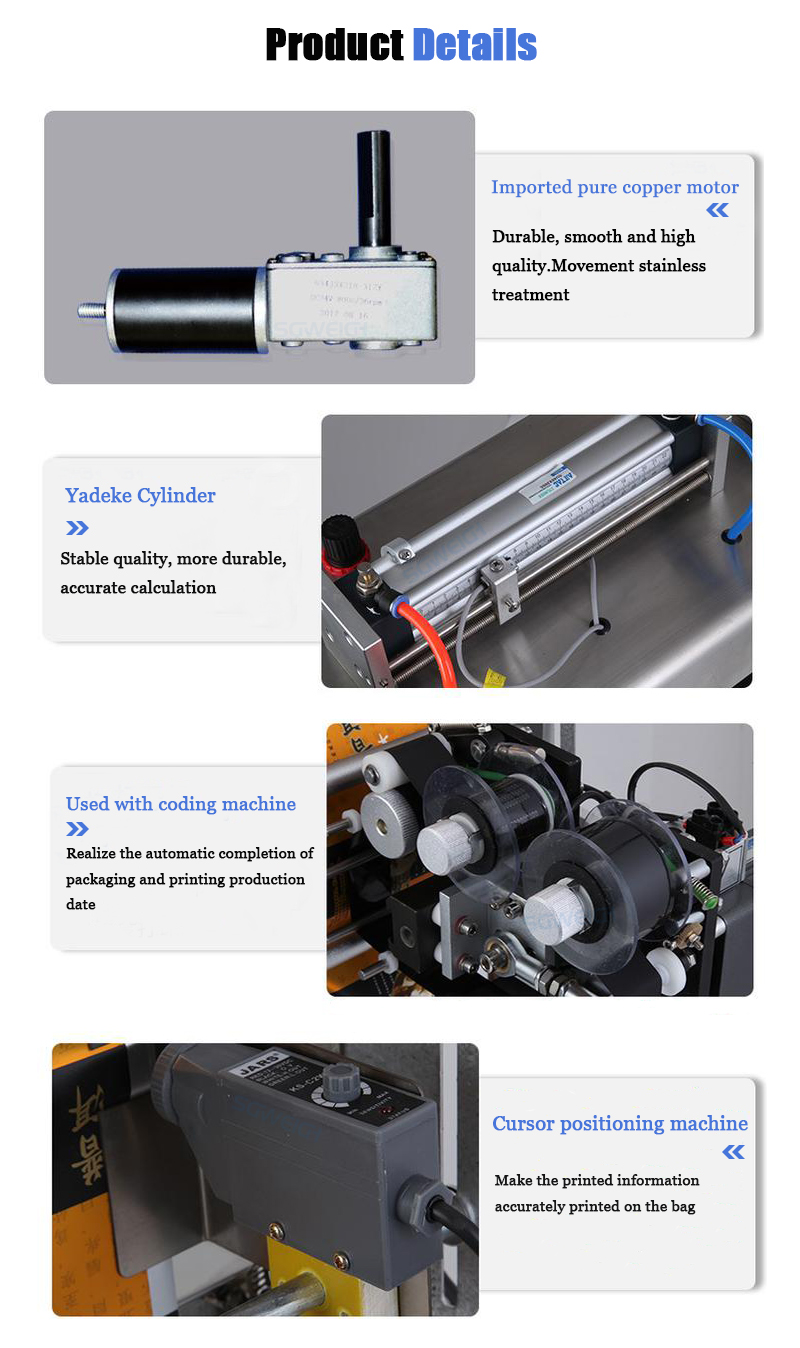

Fully automatic liquid packing machine pictures

Packaging efficiency: 30-55 bags/minute; specific speed depends on the material

Bag length range: 80-160mm

Big width range: 20-50mm

Packaging capacity: 1-50ml

Sealing form: Back seal (rounded angle/alien) custom knife mold on demand

Power requirements: 220V 50Hz; 3.8kW

Qi source requirements: 0.6MPa; 0.5m3/minute

Product specifications: 1260*960*2130mm; specific size determines 400kg according to the bag specifications

Coding method: hot coding or steel seal selection

Parameters are for reference only

Our goal is to provide you with the perfect auto liquid packing machine solution, support customization, and explain to our company the situation of packaging materials, packaging equipment (bag size, material), etc., expected output, etc., in order to provide you with suitable models. . If there are any other technical requirements, we will try our best to solve them.

Please provide the following information when sending your inquiry so that we can quickly provide you with accurate feedback and suitable solutions.

Product details (product name, min/max dimensions and weight).

Packaging details (packaging material, size, shape).

capacity and detection accuracy requirements.

Other special requirements.

1. Tentacle screen display, multiple languages are available, intuitive operation, simple.

2. The PLC computer control system is more stable, and no parameters can be adjusted without stopping.

3. You can store ten sets of parameters, and replace the variety more accurate.

4. Using dual servo motors control, the film is more accurate and faster.

5. The independent temperature control system can reach ± 1 ℃.

6. The horizontal and vertical temperature is controlled independently, and it can be well applicable to packaging materials such as membranes, PE films.

7. The packaging style is diversified (three sides, four sides, triangular bags, handbags), back sealed, inserted, pockets, punching, etc.

8. Production bags, sealing, packaging, and printing date are completed at one time.

Adaptation:

Laundry liquid or medium viscosity objects such as laundry solution, cleaner, filling, seasoning, seasoning, pharmaceutical, pesticide emulsion, fuel, pigment and other liquid or medium viscosity

Sauce, washing supplies, drinks, edible oils, jams, pigments and other high viscosity fluids and pastes.

Jam, tomato sauce, hair milk, fruit juice drink, seasoning sauce and other general liquidity bonding objects.

Shanghai Shigan Industrial Co., Ltd. specializes in research and development and production of automatic vertical packaging machines, food packaging machines, baggage packaging machines, customized production line customization, fully automatic packaging machine, and particle packaging machine. With an independent R & D institution, a complete manufacturing system, and a huge marketing service network. The packaging machine is widely used in food, medicine, daily chemical, chemical, hardware and other medium and large enterprises.

1. Service purpose: fast, decisive, accurate, thoughtful, thorough

2. Service goals: service quality win user satisfaction

3. Service efficiency: During the warranty period or out -of -war period, such as faults. After receiving the notice, our company arranges maintenance personnel to provide maintenance services for customers within 24 hours.

4. Service Principles: The product warranty period is one year. During the warranty period, our company will be damaged by components caused by quality reasons for quality reasons. The device caused by damage, the maintenance or accessories provided by our company are calculated at the cost price.

Related Products

Granular Black Tea Multi-head Weigher Packaging Machine

Vertical Particle Packaging Machine Wholesale

Mini Online Weight Sorting Check Weigher Scale

Small Dry Food Weighing Packing Machine

Multi-head Weigher Vertical Packaging Machine System

Multifunctional Granules Solid Packaging Machine

Hot Labels:automatic,liquid,sachet,bag,packing machine,4-side sealing,vertical,saline,automatic,small,packaging machine,factory