2mg Automatic Pharmaceutical Checkweigher Sample Checkweigher for Pills Tablets and Capsules Factory

Check weigher as known as checkweigher, check weighing machine, weight check machine, check weight machine, weight checker, weight sorting machine, weighing machine, and etc,.

Sample checkweigher for pills tablets and capsules are used to check for differences in the amount of capsules and to eliminate non-conforming products. The capsule weighing scale has high flexibility and can check the capsule dosage of various types of capsules without changing the mold; It can also be used for weighing and grading hollow capsules. All capsule channels of the automatic pharmaceutical smaple checkweigher are open structures, which are very easy to disassemble and clean, and can also ensure the safety of the weighing sensor. For further information about our services, or if you would like one of our professionals to contact you, please do not hesitate to contact us.

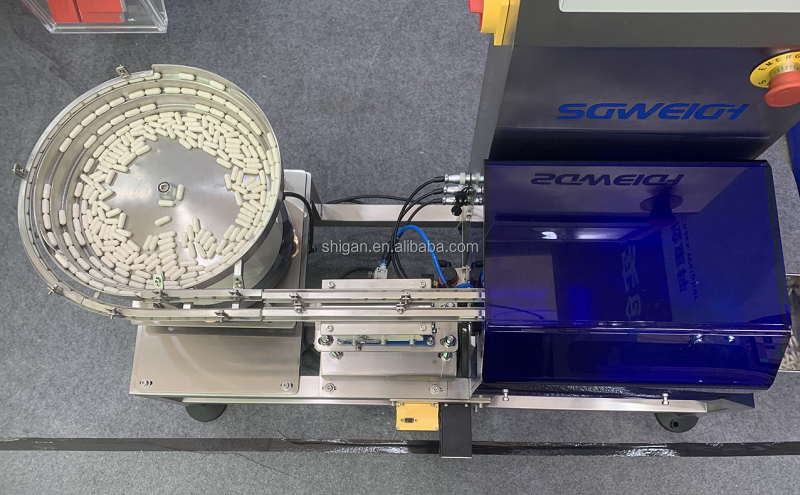

Sample checkweigher for pills tablets and capsules photos

Type SG-DJ10

Weighing Range 20-2000mg

Limited of product L: 100 W: 100 H: 2-150mm

Accuracy ±1mg Depends on product

Division Scale 1mg

Each Channel Speed 100 pcs/min

Machine Weight 80kg

Power Supply AC -220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

Shanghai Shigan provides comprehensive customized services for sample checkweigher for pills tablets and capsules applications for users in various industries, from selection, solutions, design, front-end and back-end connection auxiliary institutions to training services, aiming to meet personalized needs of users, improve production efficiency, and ensure product quality.

1. Calibration can be completed within 1 minute.

2. When the accuracy is 2.0mg, the fastest weight detection speed for each channel capsule is 150 capsules per minute.

3. Unqualified capsule collection overflow prompt.

4. All channels are displayed simultaneously in a bar chart and numerical value on the same interface, and a certain channel can also be selected for display in large numbers.

5. You can choose to display the curve and standard deviation of the first 20 capsules in any channel.

6. USB and Ethernet interfaces, supporting Modbus TCP protocol.

7. 17 inch industrial touch screen computer, capable of rotating 320 °, user-friendly interface, fast speed, large storage capacity, and high reliability.

8. Human machine interface language: Chinese, optional English.

9. In addition to exporting data from a USB drive, it is also equipped with a micro needle printer. The operator signs and confirms the paper records, which are permanently saved and cannot be changed. The quality can be traced back to the source.

10. Due to the small amplitude of loading, weighing, and removal actions of the equipment, it can also be suitable for weighing, sorting, or weight grading of hollow capsules without locking the capsule cap and body.

Shanghai Shigan Industrial Co., Ltd. is located in Shanghai, China. It is committed to the product research and development, manufacturing, sales and service of automatic equipment such as checkweighers, automatic weight sorters, and metal detectors. We always focus on automation, relying on high-quality, high-performance, and high-flexibility products to meet the needs of Chinese and foreign customers. Shanghai Shigan has strong technical strength, and our product performance is in the leading position in the industry. Our products all adopt network planning and fully adapt to the development trend of factory automation and information technology. Our products integrate high intelligence and the latest technology, and use high-reliability electrical and mechanical materials. Help customers greatly reduce labor costs, improve production efficiency, and greatly improve the pass rate, helping customers improve their industry competitiveness. We have won the recognition and praise of our customers. Main products:

Capsule and Tablet Checkweigher

Checkweigher and Labeling Machine Combo

Checkweigher and Metal Detector Combo

Waterproof PO film+wooden box

1) Dust removal and cleaning

2) Lubricating transmission components

3) Divide the machine into modules

4) Wrap the module with plastic film

5) Load the module into a plywood box

6) Mark the mark in the box

1. Equipment installation and debugging: The company provides detailed operation manuals and free operation training to enable customers to proficiently master the usage methods of the equipment.

2. Technical Support: The company provides 7x24 hours of technical support, and customers can contact engineers at any time to solve any problems they encounter during use.

3. Accessories supply: The company provides original accessories to ensure the quality and stability of the accessories.

4. Quality assurance: The company is responsible for the products sold, ensuring that the quality and performance of the equipment meet industry standards.

5. One year warranty and lifelong maintenance

Related Products

Efficient Automatic Bottle Rotary Checkweigher

Barrel Oil Wide Range Checkweigher for Automotive Parts

Liquid Sauce Pipeline Metal Detector for Food Manufacturing

In Line Mini Checkweigher for Food Industry Pouch Box

High Performance Ten-Lane Capsule Checkweigher

5kg Automatic Carton Checkweigher for Conveyor Line Chemical

Hot Labels: 2mg,automatic,pharmaceutical,checkweigher,sample checkweigher,pills,tablets,capsules,manufacturer,supply,factory,price