High Precision Capsule Tablet Sampling Checkweigher Pharmaceutical Retest Checking Weight for Pill Particle

Check weigher as known as checkweigher, check weighing machine, weight check machine, check weight machine, weight checker, weight sorting machine, weighing machine, and etc,.

The capsule tablet sampling checkweigher can achieve high-speed detection and eliminate unqualified products, ensuring that the product quality on the production line always meets the standards. The high precision pharmaceutical check weigher is suitable for capsules of various sizes, without the need for mold replacement, to meet different production needs. The capsule tablet sampling checkweigher can be connected to equipment such as capsule filling machines and tablet presses to achieve automated production. For further information about our services, or if you would like one of our professionals to contact you, please do not hesitate to contact us.

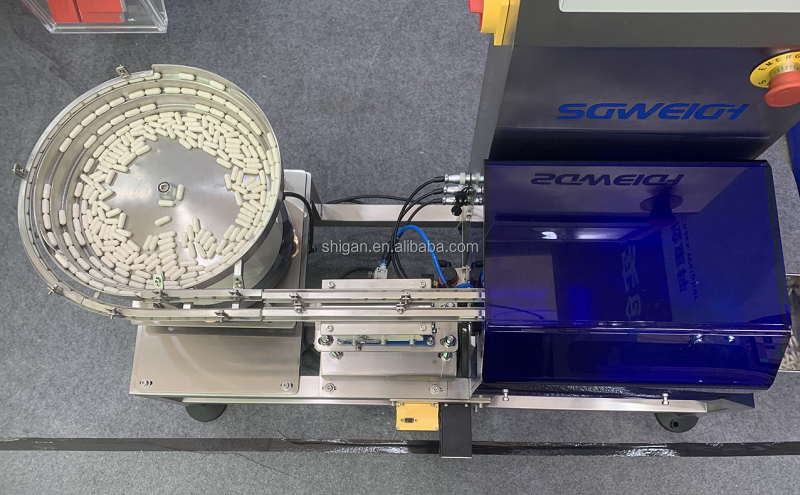

Capsule tablet sampling checkweigher photos

Type SG-DJ10

Weighing Range 20-2000mg

Limited of product L: 100 W: 100 H: 2-150mm

Accuracy ±1mg Depends on product

Division Scale 1mg

Each Channel Speed 100 pcs/min

Machine Weight 80kg

Power Supply AC -220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

The parameters are for reference only and can be customized according to requirements.

Provide the following information to our sales personnel, and our team will support you in selecting the correct type of capsule tablet sampling checkweigher:

*1. Main parameters of the tested product, product size range: length, width, height

*2. Accuracy requirement: ± g.

*3. Speed requirement: pcs/min;

*4. Product weight range:; The maximum and minimum deviations of the same product.

1. Efficient and convenient: This device can regularly or irregularly perform weight testing on small batches of capsules or tablets, ensuring stable product quality.

2. Strong compatibility: It can be directly connected to the capsule filling machine or tablet pressing machine, or can be used independently in a single machine to meet various production needs.

3. Wide adaptability: No need to change molds, suitable for various sizes of capsules or tablets, reducing production costs and equipment replacement time.

4. High degree of automation: The automatic recycling function of qualified products improves the automation level of the production line and reduces the impact of manual intervention on product quality.

5. Easy to operate and maintain: Easy to operate, easy to get started, and low equipment maintenance cost, ensuring stable operation of the equipment.

6. Data management: It can record and analyze testing data, provide production decision-making basis for enterprises, and help improve product quality and management level.

7. Compliant with GMP standards: This equipment meets the requirements of China's Good Manufacturing Practice (GMP) for pharmaceutical production, which helps enterprises successfully pass relevant certifications.

This capsule tablet sampling checkweigher can regularly or irregularly perform weight testing on small batches of capsules or tablets to ensure stable product quality.

Shanghai Shigan Industrial Co., Ltd. was established in 2010 and is a high-tech enterprise specializing in the research and development, production, and sales of testing equipment. The company is committed to the development and sales of Automatic check weigher, Digital metal detector, Food metal detection machine, Automatic weighing labeling machine, and other equipment, and has established a good reputation in the industry, becoming a well-known professional equipment manufacturer and service provider. In addition, the company also provides a series of customized services to meet the needs of customers. In order to ensure that the company can continue to launch new products, Shanghai Shigan Industrial Co., Ltd. has established a technical team with independent research and development capabilities to continuously develop innovative products.

1> Stick safety labels, tighten screws, clean, lubricate, and prevent rust;

2> Disassemble into packaging;

3> Wrap tightly with plastic film;

4> Fixed in plywood box

5> Forklift entering container

Suitable for long-distance land and sea transportation, in order to safely load and unload to the destination, we suggest that you choose full container transportation.

1. Service tenet: Shanghai Shigan Industrial Co., Ltd. is committed to providing customers with fast, decisive, accurate, thoughtful, and thorough services to meet their equipment needs.

2. Service objective: The company takes high-quality service quality as the standard, aiming to win the satisfaction and trust of users.

3. Service efficiency: The company promises to provide effective solutions within 24 hours in the event of equipment failure, ensuring that customers' production progress is not affected.

4. Service principle: The company's product warranty period is twelve months. During the warranty period, for equipment damage caused by quality reasons, the supplier will provide free repair and replacement parts. If the equipment parts are damaged outside the warranty period, the supplier will only charge the cost price. For equipment damage caused by customer human factors, the supplier's repair or parts provision will be calculated at cost.

Shanghai Shigan Industrial Co., Ltd. always adheres to providing customers with high-quality products and services, ensuring that customers have no worries during the use of the company's products. The company is full of sincerity and looks forward to establishing long-term and stable cooperative relationships with our customers to jointly develop and grow.

Related Products

SG-6X Food Small Strip Pouch 6-line Multi-lane Check Weigher

SG-Z High-speed Bottle Rotary Weighing Checkweigher for Assemble Line

SG-1X High-precision Balance Grade Check Weigher for Small Pouch

High Precision Can Multi-level Weight Sorting Machine

Aluminum Foil Food Checkweigher and Metal Detector Combo

50kg Large Volume Industrial Dynamic Checkweigher

Hot Labels: high precision,capsule,tablet,sampling checkweigher,pharmaceutical,retest,checking weight,pill,particle,manufacturer,supply,factory,price