Stable High-precision Slender Bottle Check Weigher Clamping Conveyor Juice Beverage Check Weighing Scale Supplier Price

Check weigher as know as checkweigher, check weight machine, weight checker, weight sorting machine, check weighing machine, weighing scale, and etc,.

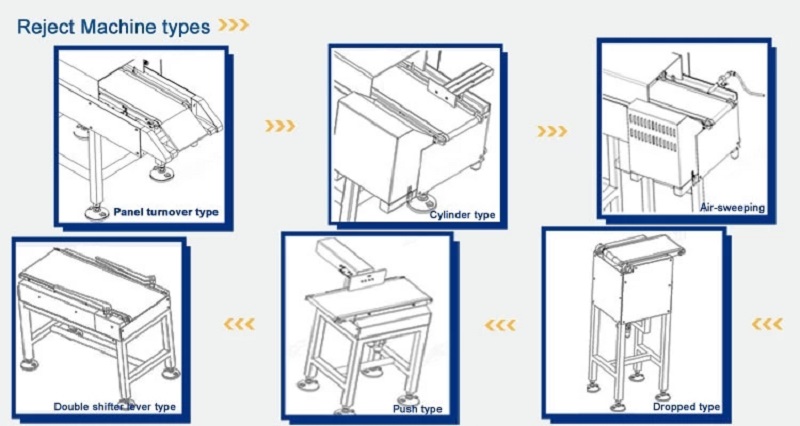

The slender bottle check weigher is designed for fully automatic packaging lines. When overweight or ultra light is found, the product conveyor belt will stop and alarm, and the screen will display the weight. The clamping conveyor check weigher helps users to weigh and troubleshoot weight anomalies online, supporting communication protocols such as Ethernet, RS232, 485, etc. The weighing scale has complete specifications and supports exclusive customization services. Our product specifications and sizes are rich, various styles, welcome to contact us for quotation information.

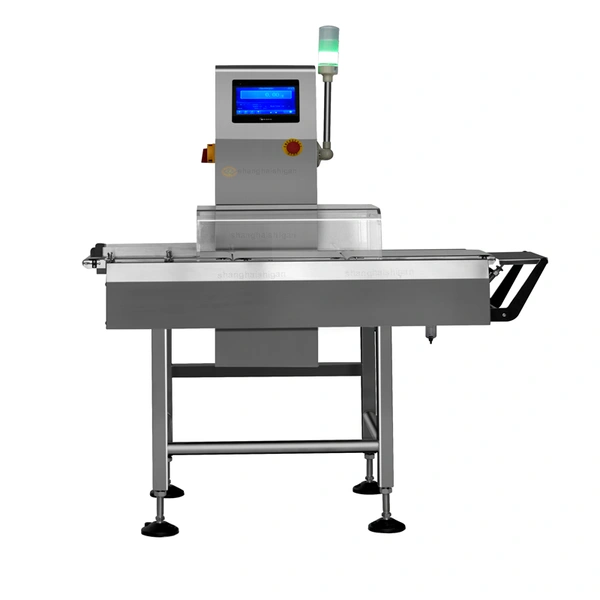

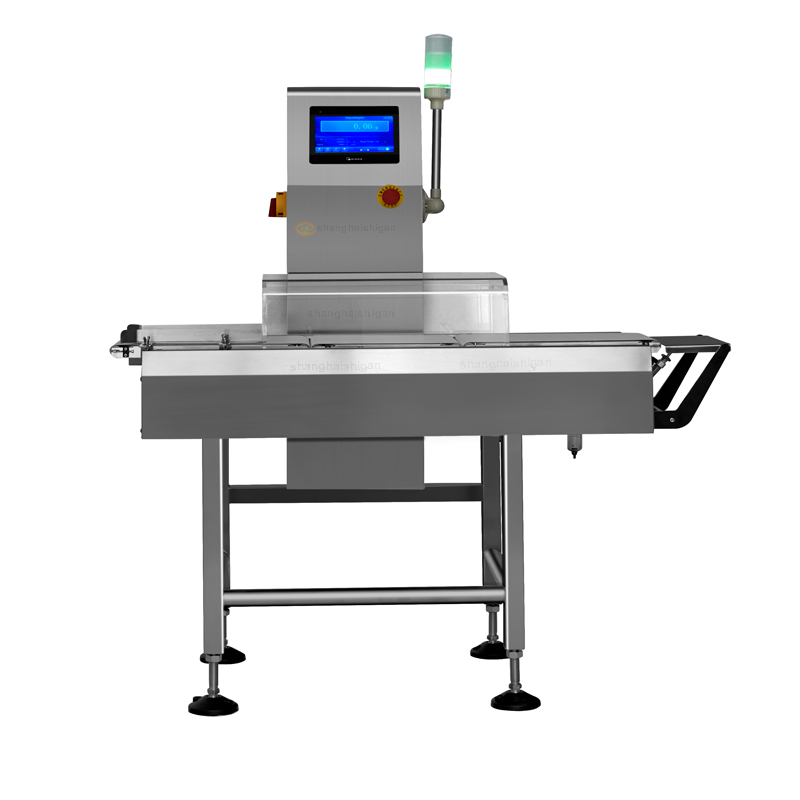

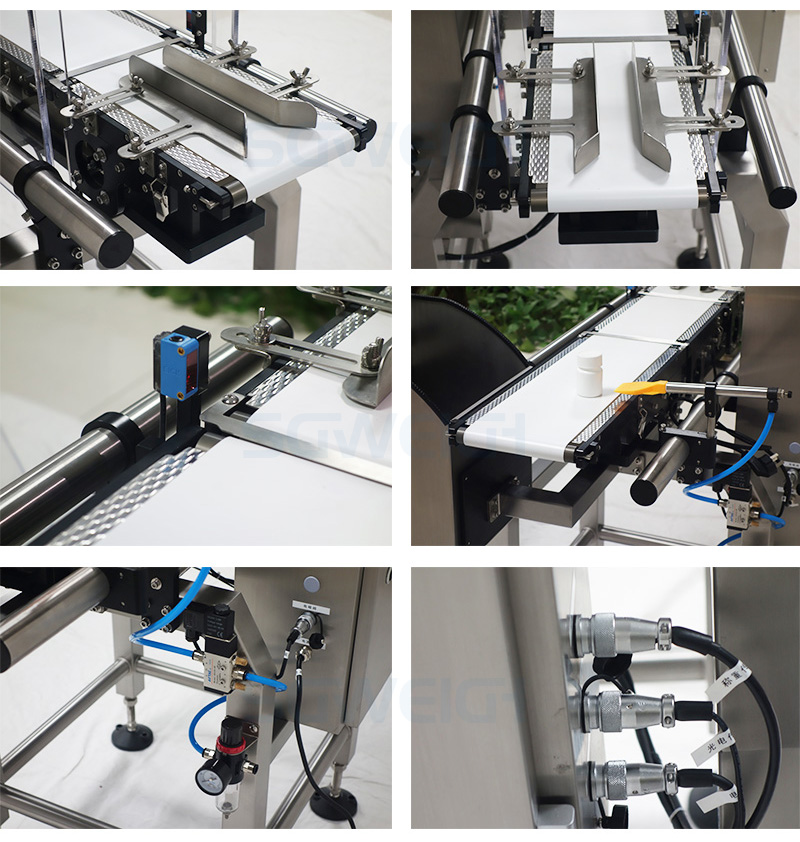

Clamping conveyor check weigher pictures

1. Improve the efficiency of the production line and improve the efficiency of the entire equipment.

2. The accuracy of the slender bottle check weigher ensures that customer interests are not affected.

3. The use of slender bottle check weighers can reduce potential sampling errors and long-term labor costs.

4. Improve product quality to meet the strict needs of customers.

5. Cost savings increase product profits.

6. Use a slender bottle check weigher feedback control to ensure effective filling equipment for direct control or automated feedback control through the factory's existing network system.

7. Ensure 100% weight testing by using online bottle check weighers to ensure that all products meet regulatory requirements.

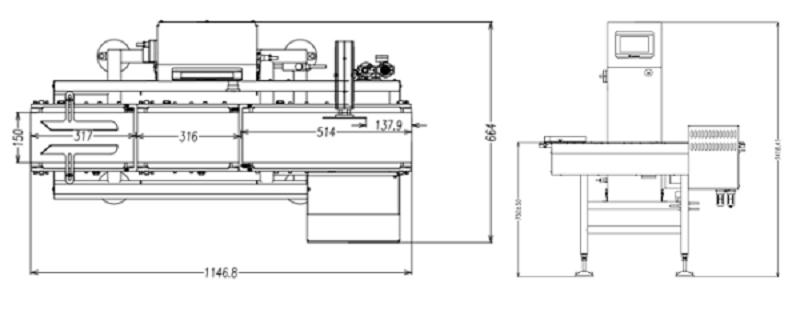

Type SG-150

Weighing Range 3-600g

Limited of product L: 200 W:150 H: 3-200mm

Accuracy ±0.1g Depends on product

Division Scale 0.1g

Belt Speed 0- 65 m/min

Max Speed 150 pcs/min

Belt Width 150mm

Machine Weight 60kg

Power Supply AC 110/220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

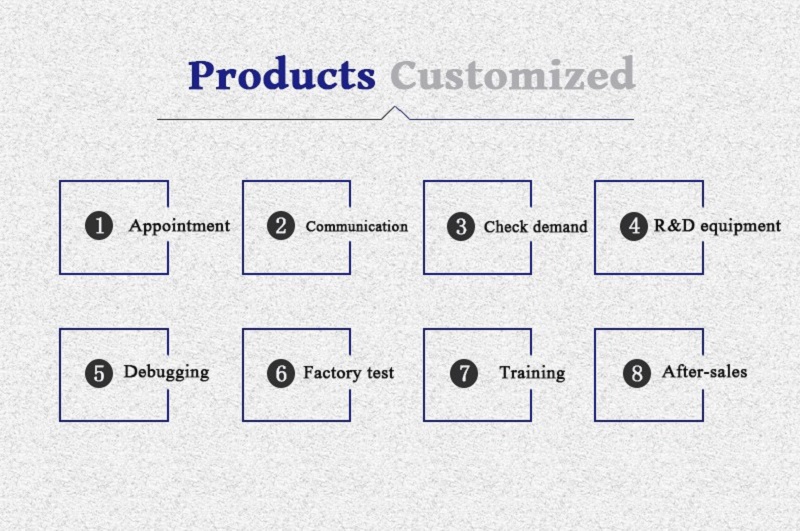

1st step: Customer has showed his special requirements.

2nd step: We try to understand the conception and pattern from customer with simple draft or refer picture.

3rd step: Making the conceptive CAD drawing based on communication and understanding.

4th step: Making the detail and 3D drawing agter fixed the design and other details.

5th step: Offer the quotation after confirm the design,material and surface treament.

6th step: Making the sample for approval.

7th step: Testing installation after demo mock up.

8th step: Big production delivery and service after sales.

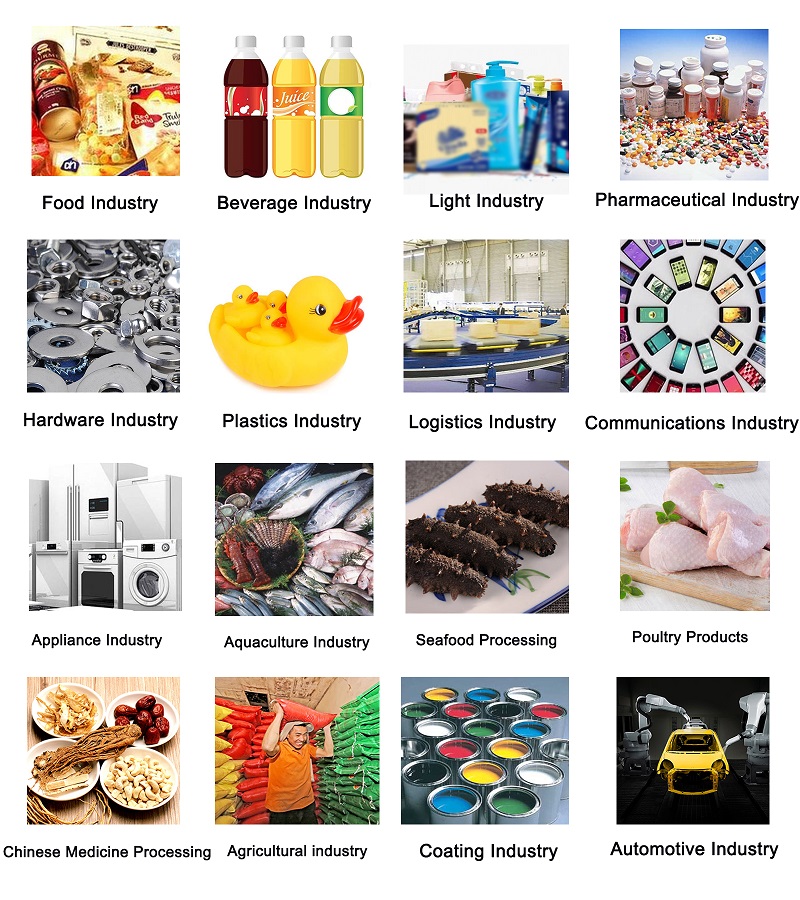

1. Underweight detection and overweight detection of packaged products; Detection of missing accessories within the packaging, such as instructions, accessories, gifts, desiccants, and other accessories.

2. Full box inspection: missing parts inspection, missing packages inspection, missing boxes inspection, missing bottles inspection, missing cans inspection, missing bags inspection, etc.

3. USB data storage interface, which can transfer report data to a PC for analysis and printing; Password protection for parameter settings, only operated by management personnel.

Our company introduction

1. Established in 2010.

2. High tech enterprises in Shanghai.

3. We have over 10 years of experience in the field of automatic check weigher machinery and have our own factory, which can provide you with the most suitable projects for your needs.

4. 6-8 international machinery exhibitions per year.

5. Supply OEM/ODM manufacturing.

6. Multiple engineers to ensure quality/service.

As manufacturers and traders, we have good quality and price control over our products.

8. The products are exported to over 40 countries such as the United States, Canada, and Mexico; Australia, New Zealand; Saudi Arabia, Italy, Spain; France, Poland, Is

Packing Detail:

Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.

Delivery Detail :

Shipped in 15 days after payment

12 Months Guarantee

★ 12 months free main parts change (Please return the damaged parts by airmail

★ Overseas engineers available (You only have to pay part of the freight)

Customization

All our machines can be customized , according to your product's features and your workshop environment, or your production line.

After-sales Service Provided

Engineers availbale to provide after-sales service overseas in order to help customers solve technical problems.

Related Products

250g Automatic Packing Machine For Grain Rice Granules

Intelligent Digital Linear Scale Manufacture Price

Sugar Cookies Metal Detector With Light And Sound Alarms

Bottel Bag Liquid Filling Machine For Sauce Paste

Small Size Rice Spices Powder Sachet Packaging Machine

High Speed Boxed Medicine Mini Check Weigher

Hot Labels: stable,high-precision,slender bottle,check weigher,clamping conveyor,juice,beverage,check weighing scale,supplier,price,weight checker,factory