SG-Z High-speed Bottle Rotary Weighing Checkweigher for Assemble Line

Check weigher as know as checkweigher, check weight machine, weight checker, weight sorting machine, check weighing machine, weighing scale, and etc,.

The operation of the bottle rotary weighing checkweigher is simple, intelligent, and fast. After entering the background and setting the upper and lower limits and reference values in normal mode, it can be automatically learned several times using standard products. The automatic bottle checkweigher is widely used to check the weight of filling packaging during movement, and any product that exceeds or falls below the set weight is rejected. To know more about us, please you do not hesitate to contact us or visit our factory.

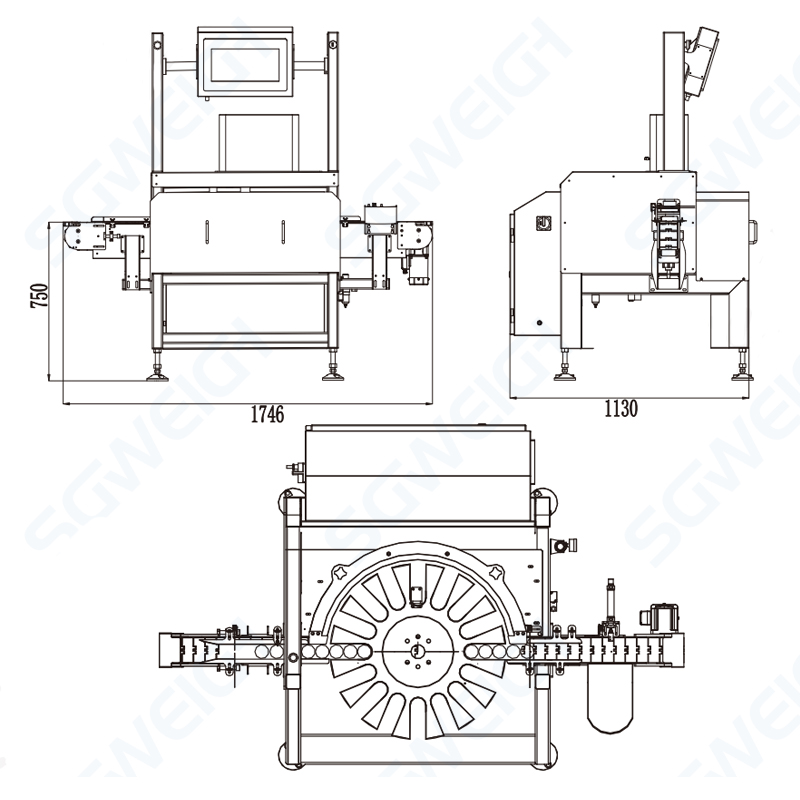

The bottle rotary weighing checkweigher mainly consists of a front-end chain plate for feeding, clamping the turntable, weighing module, discharge chain plate, and removal.

1. Front end chain plate feeding: The front end feeding chain plate conveys the tested products one by one to the turntable through photoelectric induction..

2. Clamping turntable: mainly used to clamp the corresponding quantity of products into the weighing module, ensuring the accuracy of the quantity.

3. Weighing module: completes the collection of weight signals. When the tested product passes through the weighing module, all weight data of the entire process is analyzed and calculated to calculate the weight of the tested product. At the same time, the weighing module will determine whether the weight data obtained is within the required weight range.

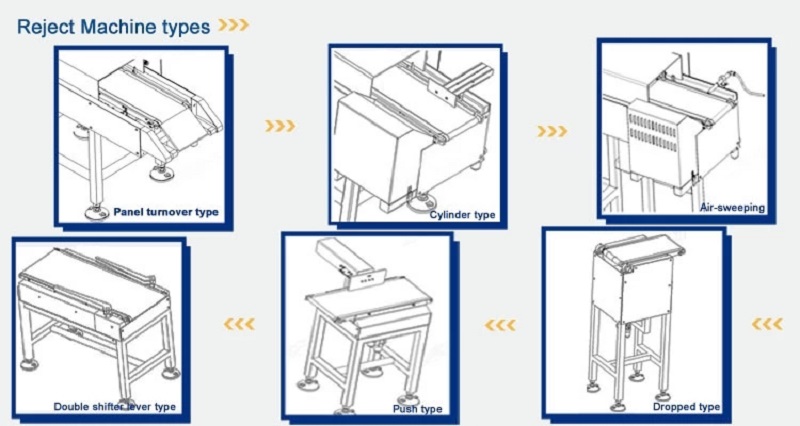

4. Belt removal: When the product passes through this conveyor belt, it will continue to be transported back if it is qualified. If it is not within the required weight range, the machine will activate the removal mechanism to remove products that are not qualified (overweight/too light) in weight.

Automatic bottle rotary weighing checkweigher pictures

Type SG-Z

Weighing Range 2-300

Restrictions of Products:φ10-100 H:20-200mm

Limited of product L: 180 W: 40 H: 2-20mm

Accuracy ±0.01g Depends on product

Division Scale 0.01g

Belt Speed 0- 50 m/min

Max Speed 60 pcs/min,120 pcs/min,180 pcs/min(optinal)

Belt Width 100mm

Machine Weight 260kg

Power Supply AC 110/220V ±10% 50HZ

Power 400W

Main Material SU304 stainless steel

Shanghai Shigan can tailor a machine that meets the needs and specific scenarios of customers according to their usage needs. Meet the personalized needs of customers in terms of functionality, performance, appearance, etc.

1. Large size color LCD touch screen interface, easy to operate, clear display, and easy for users to quickly get started.

2. Support customization in multiple languages, with default settings of Chinese and English to meet the needs of different users.

3. Equipped with an empty bag photoelectric automatic detection function, the conveyor belt speed can be adjusted to improve detection efficiency.

4. Set up three-level password protection to ensure that only management personnel can operate the device and ensure data security.

5. Support exporting product weighing data through USB for easy data statistics and analysis.

6. Equipped with power outage protection function, the equipment parameters remain unchanged in case of accidental power outage to avoid data loss.

7. It can store testing data for 100 different products, making it convenient for users to switch and call.

8. Data statistics function, real-time display of the total number of products passed, the total number of products that are too light, and the total number of products that are overweight.

9. The mechanical structure is simple, and the buckle conveyor belt is easy to disassemble, clean, and maintain, meeting GMP and HACCP specifications.

10. Automatic dynamic compensation value and dynamic zero tracking function ensure the reliability of detection data.

11. The curve/bar chart displays the statistical distribution of sorting (re inspection) results, and the window displays the values of the last 10 re inspection results.

12. Adopting patented technology, independently developed microcontroller system, unique filtering algorithm, ensuring ultra-high accuracy and reliability, and ensuring stable operation of the system.

1. Bottle rotary weighing checkweigher is used for automatic weight detection, upper and lower limit discrimination, or weight grading selection on various automated assembly lines and logistics conveying systems, and can also be used for detecting multiple or missing parts after product packaging.

2. Widely used in online testing in industries such as pharmaceuticals, food, cosmetics, chemicals, and hardware.

3. Bottle rotary weighing checkweigher can directly replace manual weighing to protect customer brand image, improve customer production efficiency and quality.

Shanghai Shigan Industrial Co,.Ltd

Our advantages are as follows:

1. Strong R&D team: We have a professional R&D team dedicated to continuously improving and innovating weighing scale technology to meet the needs of the market and customers.

2. CE certificate: Shanghai Shigan has obtained the CE certificate, which proves that our product quality and safety comply with European standards and can be used with confidence.

3. Domestic and international sales network: Our products are sold throughout the country and are exported to multiple countries and regions such as Russia, Siberia, Inner Mongolia, Vietnam, Myanmar, Southeast Asia, Africa, etc.

4. Professional Services: We provide customers with a comprehensive range of professional services, including product selection, usage training, maintenance, etc., to ensure that customers have no worries during the use process.

5. High quality products: Shanghai Shigan is committed to manufacturing high-quality products, using patented technology and unique filtering algorithms to ensure the ultra-high accuracy and reliability of the weighing scale.

6. Competitive prices: We adhere to providing customers with high-quality products and competitive prices, helping them reduce costs and improve production efficiency.

7. Our Main products: automatic check weigher, digital metal detector, food metal detection machine, automatic weighing labeling machine, checkweigher and metal detector combo, and etc,.

Export fumigation free plywood box with quick connection design, easy to open and reuse;

The inner plastic film is wrapped to protect the goods from salt, wind, or damage;

Pre sales service:

1. Inquiry and consulting support: Provide customers with detailed product information and technical advice to help them understand and choose suitable products.

2. Sample testing support: Provide customers with free sample testing to ensure that the product meets their specific needs.

3. Visit our factory: Invite customers to visit the factory to understand the product production process and quality control system, and enhance customer confidence in the product.

After sales service:

1. Training support: Provide customers with training on installing and using machines to ensure they are proficient in operating the equipment.

2. Technical Support: Provide continuous technical support to help customers solve technical problems encountered during use.

3. Accessories supply: one-year warranty, lifelong maintenance to provide high-quality accessories, ensuring the stable operation of the equipment.

4. Repair Service: Provide timely and efficient repair services to customers, reducing the impact of equipment failures on production.

Related Products

SG-1X High-precision Balance Grade Check Weigher for Small Pouch

High Precision Can Multi-level Weight Sorting Machine

Aluminum Foil Food Checkweigher and Metal Detector Combo

50kg Large Volume Industrial Dynamic Checkweigher

Small Sachet Light Industry Mini Checkweigher

Liquid Meat Sauce Digital Metal Detector for Food Industry

Hot Labels: high-speed,bottle checkweigher,rotary weighing,checkweigher,assemble line,check weigher,manufacturer,supplier,factory,price