High Speed Boxed Medicine Mini Check Weigher Instructions Overweight Underweight Assembly Line Check Weight Machine

The boxed medicine mini check weigher is a specialized equipment for modern automatic production workshops, mainly used for weight supervision and testing of various daily chemical products. Check whether the weight of the product is qualified, whether there is overweight or underweight, and whether there are a few missing parts., The automatic check weigher system adopts the HBM weighing module imported from Germany, which accurately identifies weight and quality abnormalities. It has a complete range of specifications and supports exclusive customization services, welcome to contact us for quotation information.

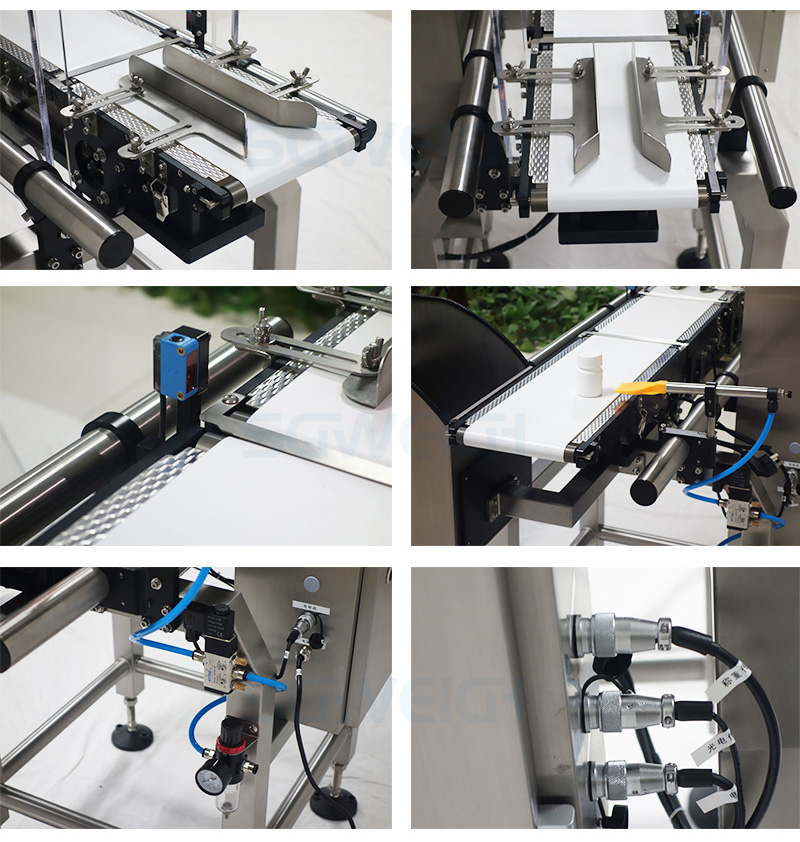

Boxed medicine mini check weigher pictures

Type SG-100

Weighing Range 3-500g

Limited of product L: 200 W:150 H: 3-200mm

Accuracy ±0.1g Depends on product

Division Scale 0.1g

Belt Speed 0- 65 m/min

Max Speed 150 pcs/min

Belt Width 150mm

Machine Weight 60kg

Power Supply AC 110/220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

The parameters are for reference only

Our Mission

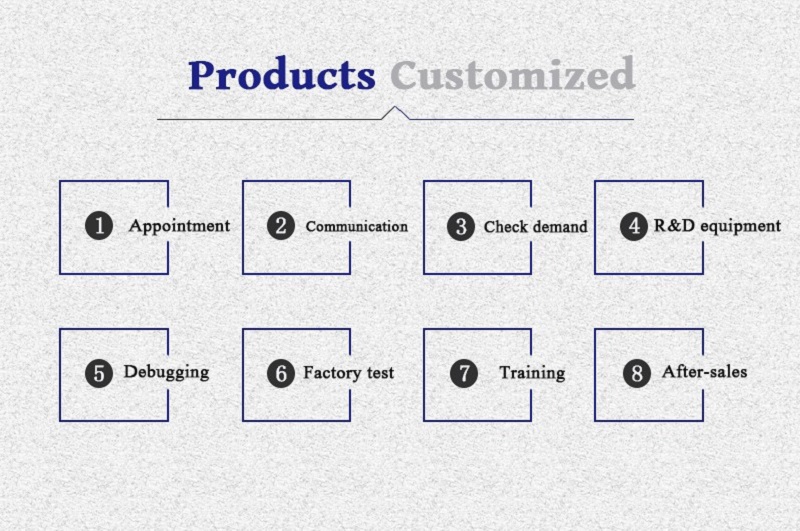

We are committed to providing customers with customized automatic check weigher solutions. If you have any requirements in this regard, you can click on online communication or send us WhatsApp. Explain to our company the condition of the tested materials (dimensions, materials, etc.), expected production, etc., in order to provide you with a suitable model.

1.Strong practicality: 10 inch high color, high-resolution human-machine interface, easy to operate and friendly;

2.High stability: 24-hour high-speed and high-precision operation. Advanced and rigorous design concepts greatly reduce mechanical system failures and improve production efficiency;

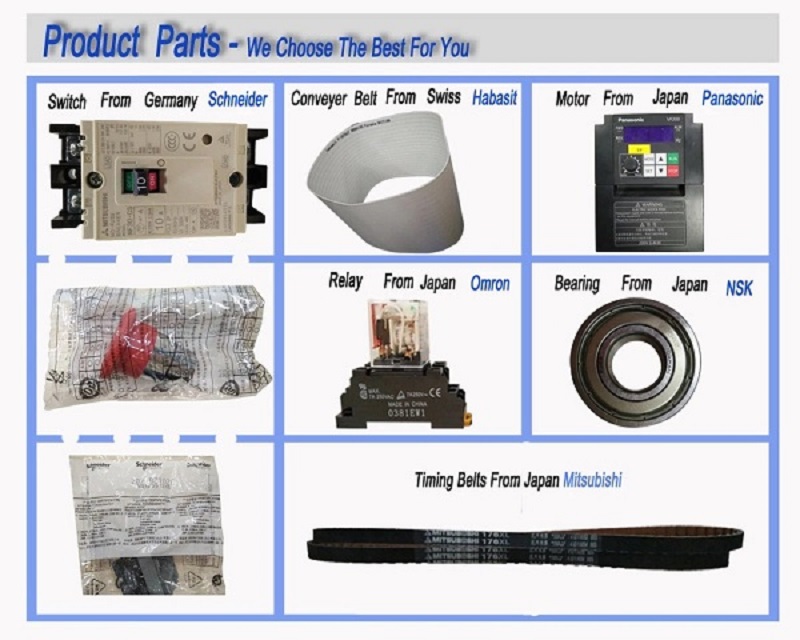

3.High speed and precision: using high-speed and high-precision German HBM sensors

4.Material accessories: The entire body structure is made of 304 stainless steel, which is anti-theft, anti-corrosion, and has a long service life.

5.The weight inspection data is equipped with a standard USB interface and can be exported to Excel tables

6.Easy to maintain: Unique conveyor belt structure design, modular design, easy disassembly and cleaning, protection level IP65.

7.Easy to connect: Adopting a DC brushless motor, it is more stable and has a smaller and more refined structure. Suitable for larger speed requirements.

8.Easy to switch: can store 99 product formulas, and change product parameters with just one click.

1. Underweight detection and overweight detection of packaged products; Detection of missing accessories within the packaging, such as instructions, accessories, gifts, desiccants, and other accessories.

2. Full box inspection: missing parts inspection, missing packages inspection, missing boxes inspection, missing bottles inspection, missing cans inspection, missing bags inspection, etc.

3. USB data storage interface, which can transfer report data to a PC for analysis and printing; Password protection for parameter settings, only operated by management personnel.

Shanghai Shigan Industrial Co,.Ltd is located in Shanghai, China, with a young team specializing in the development and production of packaging machinery and equipment for pharmaceuticals, food, pesticides, daily chemicals, and chemical industries. Introduce domestic and foreign technologies and continuously improve products. Our products are distributed throughout the country and exported to various parts of the world such as the Americas, Europe, Africa, and the Middle East. We provide quality tracking services, free maintenance during the warranty period, and lifelong maintenance. Our main products are: automatic checkweigher, digital metal detector, vertical packaging machine, prefabricated bag packaging machine, multi-head scale, linear scale, packaging machine and a series of assembly line packaging testing equipment.

Export fumigation free plywood box with quick connection design, easy to open and reuse;

The inner plastic film is wrapped to protect the goods from salt, wind, or damage;

In order to ensure that customers can purchase our products with confidence, our company makes four major commitments to our customers:

1、 Service tenet: fast, decisive, accurate, thoughtful, and thorough

2、 Goal: Satisfy all users with high-quality and thoughtful service

3、 Service efficiency: In case of equipment failure during or outside the warranty period, provide a solution as soon as possible

4、 Warranty principle: The product warranty period is twelve months. During the warranty period, the supplier will repair and replace parts damaged due to quality reasons free of charge. For parts damaged outside the warranty period, the provided parts will only be charged at cost. For equipment damage caused by human factors on the demand side, the supplier's maintenance or provided parts will be calculated at cost.

Related Products

Quantitative 10 Heads Weigher Wholesale Price

Pet Food Cat Strips Multi-lane Packing Machine

Seeds Single-head Linear Weigher 2-head Linear

High Accuracy Vertical Digital Metal Detecor

Small Liquid Soap Products Filling Machine

Pouch Spice Powder Premade Bag Packing Machine

Hot Labels: high speed,boxed medicine,mini check weigher,automatic check weigher,instructions,overweight,underweight,assembly line,check weight machine,price,manufacturer