Efficient Bottled Daily Necessities Rotary Check Weigher Customized Automatic Rotating Check Weighing Scale Price

Checkweigher as known as check weigher machine, check weight machine, check weighing machine, weight sorting machine, weight checker, weight sorting machine, and etc,.

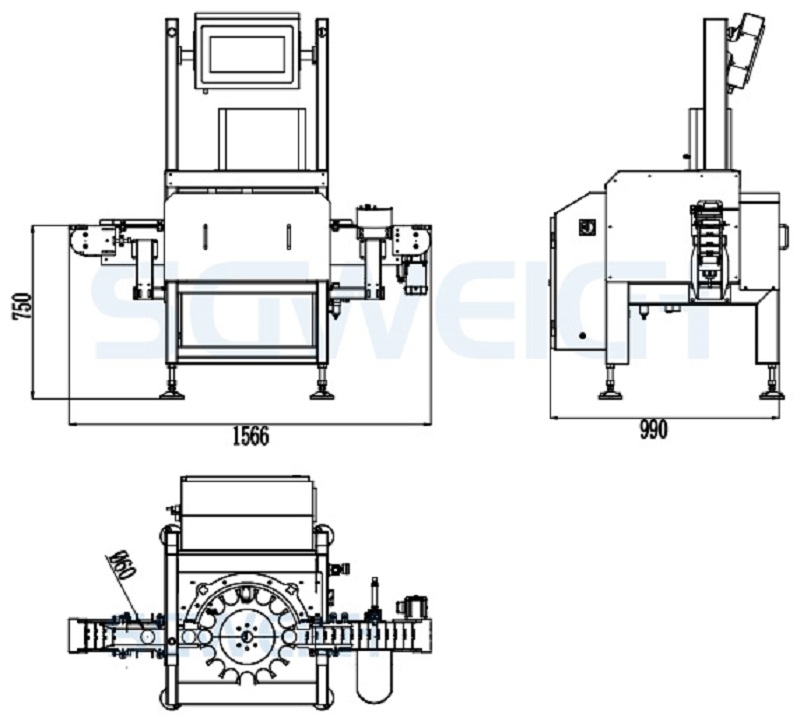

The bottled rotary check weigher mainly consists of a front-end chain plate for feeding, clamping the turntable, weighing module, discharge chain plate, and removal. High quality components and sturdy structural design ensure minimal maintenance requirements. The automatic rotating check weigher scale is an excellent quality control solution, with high-precision weighing control to reduce product waste. Our product specifications and sizes are rich, various styles, welcome to contact us for quotation information.

Bottled rotary check weigher photos

1. Large size color LCD touch screen interface, simple operation and intuitive display.

2. Support customization of multiple languages, default to Chinese and English.

3. Equipped with empty bag photoelectric automatic detection, and the conveyor belt speed can be adjusted.

4. Three levels of password protection for parameter settings, only operated by management personnel.

5. Product weighing data can be exported through USB.

6. Power outage protection function, with accidental power outage parameters remaining unchanged.

7. The parameters of different products can be set to store 100 types of detection data, making it convenient for users to switch and call.

8. Data statistics function. The total number of products passed over a period of time/the total number of products that are too light/the total number of products that are overweight.

9. The mechanical structure is simple, and the buckle type conveyor belt is convenient for disassembly, cleaning, and maintenance. Complies with GMP and HACCP specifications.

10. Automatic dynamic compensation value, dynamic zero point tracking, including zero point tracking during continuous equipment operation, to ensure reliable detection data.

11. The curve/bar chart displays the statistical distribution of sorting (re inspection) results, and the window displays the values of the last 10 re inspection results.

12. Adopting patented technology, the microcontroller system is independently developed, with a unique filtering algorithm that has ultra-high accuracy and reliability. Ensure system stability.

Model SG-Z1

Weighing range 5-300g

Minimum scale 0.01g

Maximum sorting speed of 50 pieces/minute (one channel)

Conveying speed 20-100m/min

Operation mode: Touch based operation

Conveying direction facing the touch screen from left to right

Removal method: air blowing removal/push plate removal

Belt height above ground 750 ± 50mm (customizable according to customer requirements)

Machine structure stainless steel (SUS304)

Power supply 220V 50-60HZ

Power approximately 300W

The above parameters are for reference only and can be customized according to requirements.

How to choose a weighing scale?

-Confirm project requirements, such as product size, weight, accuracy, and expected speed.

-Ensure that the rack is stable and free from vibration during standstill or operation.

-Exquisite workmanship.

-The components have good quality and long-term reliable performance.

-Easy to operate and use.

1. Bottled rotary check weigher is used for automatic weight detection, upper and lower limit discrimination, or weight grading selection on various automated assembly lines and logistics conveying systems, and can also be used for detecting multiple or missing parts after product packaging.

2. Widely used in online testing in industries such as pharmaceuticals, food, cosmetics, chemicals, and hardware.

3. In addition, bottled rotary check weigher can directly replace manual weighing to protect customer brand image, improve customer production efficiency and quality.

Shanghai Shigan Industrial Co., Ltd., is located in Shanghai, China, and has been specializing in the production of packaging machines, weighing scales, metal testing machines and other assembly line equipment for over 13 years. We have our own factory, and since its establishment, our company has been committed to the new technology field of packaging machines. Now, we have formed a special competitive market based on advanced technology. We have obtained the CE certificate. Main products: automatic packing machine, packing machine multi-head weigher system, linear weigher, multihead weigher, weighing filling machine, vacuum packing mahcine,check weigher, metal detector, etc.

Packaging:

1. Outer packaging: standard export wooden box

2. Inner packaging: The product is wrapped in carefully stretched film, with hard wooden boards and strong bandages fixed at the edges and corners.

3. Inspection team: Professional personnel inspect and classify your goods.

1) Warranty Time: 1 year, within this period we offer spare part replacement freely if there are any Non artistic damage on them

2) Quality: Quality of products will be strictly checked and every machine will be tested to ensure it can work well before packaging

3) Technical services: We will keep contacting with our customers all the time after selling out the machine Please contact us without station if you need any help on machines

4) File Services: We offer instruction manual and video to teach you how to use and testing machine

5) Accessories: We supply spare parts with competitive price after warranty time

Related Products

400gm Besan Vertical Granules Packing Machine

5kg Spices Chilli Powder Vacuum Packaging Machine

Automatic Multi-lane Liquid Packing Machine

Loose Tablet Capsule Digital Metal Detecor

High Precision Granular Medicine Multi-head Weigher

Sachets Sticks Pouches Powder Packing Machine

Hot Labels: efficient,bottled,daily necessities,rotary,check weigher,checkweigher,customized,automatic,rotating,check weighing scale,supplier,factory,price