SG-150 High Accuracy Check Weigher Machine for Box Automatic Checkweigher

Check weigher as know as checkweigher, check weight machine, weight checker, weight sorting machine, check weighing machine, weighing scale, and etc,.

The high accuracy check weigher machine is an indispensable equipment in automated production lines, whose main function is to accurately weigh packaged products and ensure that the weight of the products meets the predetermined standards. When the automatic checkweigher for box detects overweight or ultra light products, the system will immediately stop the conveyor belt and issue an alarm signal, displaying abnormal weight on the screen to notify the operator. Meanwhile, non-conforming products on the production line will be automatically removed. Our product specifications and sizes are rich, various styles, welcome to contact us for quotation information.

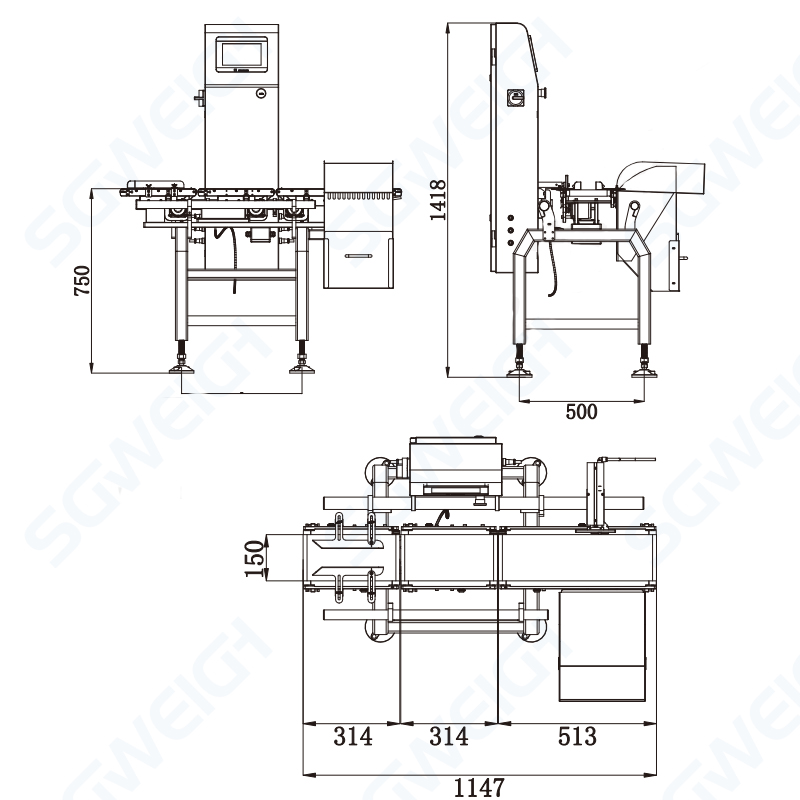

Automatic checkweigher for box pictures

Type SG-150

Weighing Range 3-500g

Limited of product L: 200 W:150 H: 3-200mm

Accuracy ±0.1g Depends on product

Division Scale 0.1g

Belt Speed 0- 60 m/min

Max Speed 150 pcs/min

Belt Width 150mm

Machine Weight 80kg

Power Supply AC 110/220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

Note 1) Selection ability and accuracy. It varies depending on the actual tested product and the selected part.

Note 2) The size of the measurable product may vary depending on the specific specifications of the selection part. Please choose the high accuracy check weigher machine according to the size of the product. If the product is semi transparent or transparent, please discuss the specific situation with us.

Note: The noise level of this machine is below 70Db.

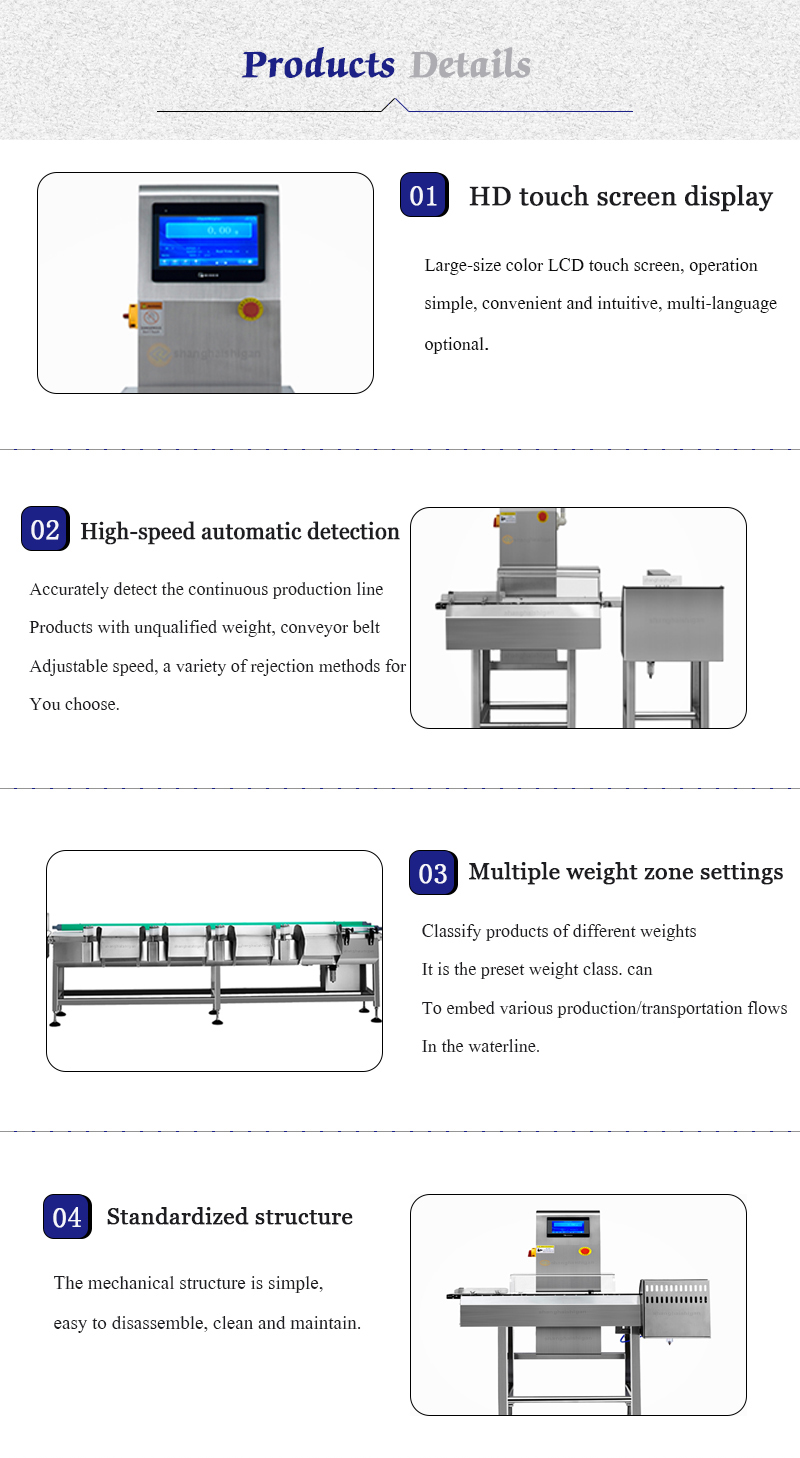

1. The open stainless steel frame provides convenience for thorough cleaning. No tools required to remove conveyor belt, simplified

2. Clean up the program and reduce cleaning time. The storage card can store up to 100 operating parameters to minimize operator errors and minimize production downtime.

3. The bright and clear touch screen text facilitates error cost production control to achieve maximum weighing performance.

4. Integrate centralized management system data with upstream and downstream equipment to optimize production line productivity.

5. The calibration control signal from the weighing scale to the upstream spiral filling machine can improve productivity.

6. The automatic checkweigher for box provides additional quality control in a space saving system.

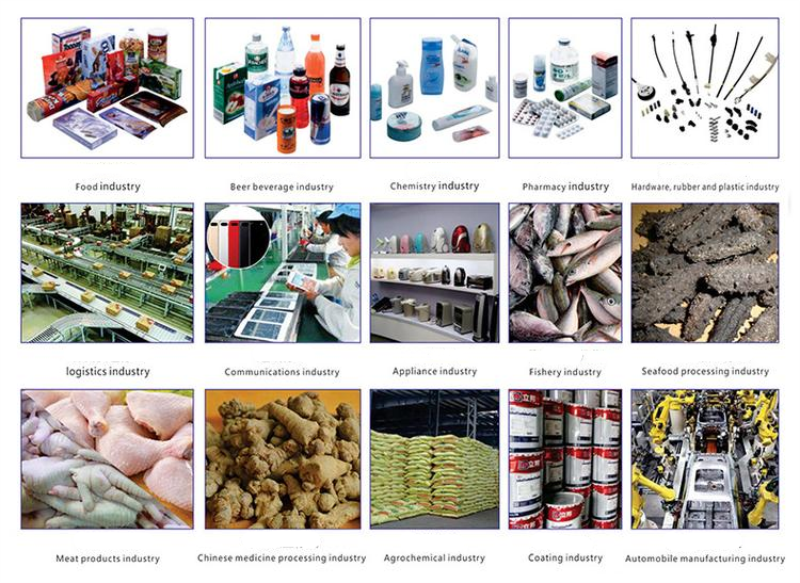

High accuracy check weigher machines are widely used in many industries such as pharmaceuticals, food, chemicals, beverages, and health products. For example, it can be used in the food industry to detect the weight of bread, cake, ham, instant noodles, frozen foods, food additives, preservatives, etc.

1. Competitive prices. As an original manufacturer, we have our own modern workshop processing facilities, and we can control good quality and cost ourselves.

2. Respond quickly. A well-trained professional sales team, working 24/7, responds to inquiries and questions within 24 hours.

3. Delivery on time. Ordered products are always delivered on time, which not only helps save time but also helps our customers save costs. Timely delivery enables our customers to inspect the product before proper use. We also value our punctuality and provide customers with fault free products.

4. Integrity and professional marketing policies. We will always support you. We are committed to providing customers with the best possible service with a completely honest attitude. Specialization to fully satisfy our customers.

5. Low maintenance. The products delivered according to customer requirements not only have excellent quality, but also have low maintenance costs.

6. Storage of parts and accessories. We have sufficient parts and accessories for each machine.

7. Flexible customization of ODM capabilities and aging testing 7 * 24 hours prior to shipment.

The Delivery Date: After receiving the payment, the delivery date will be within 15-30 working days

Packaging: Protective film + wooden case

Logistics: Air, sea or express (DHL, etc.)

The Freight: The cost of transport depends on the destination, mode of transport and the weight of the goods

Pay: T/T, Western Union, paypal

1. Customer consultation and technical support: Provide customers with consultation services related to product use, repair, and maintenance, and answer any problems they encounter during operation and use.

2. Technical training: Provide training on product operation, maintenance, and repair to meet customer needs, ensuring that customers can use and maintain products correctly.

3. Accessory supply: Provide original accessories to ensure the quality and performance of the accessories and meet the needs of users.

4. One year warranty and lifelong maintenance

6. After sales service tracking: Track and provide feedback on the after-sales service process, timely understand customer needs and opinions, and continuously improve service quality.

Related Products

20g Multi Lane Check Weigher with High Efficiency Conveyor

200g High Speed Box Check Weigher for Cosmetic

Chemical Particle Powder Vertical Metal Detector

Industrial Metal Detector Reject System

Ultra-narrow Bottle Online Check Weigher for Production Line

Digital Metal Detector for Tablets Capsules

Hot Labels: high accuracy,check weigher machine,checkweigher for box,automatic checkweigher,supplier,price,factory,manufacturers