Health Medicine Capsule Counting Check Weigher Machine High Efficiency Dynamic Checkweigher For Sugar Coated Tablets

Check weigher as known as checkweigher, check weighing machine, weight check machine, check weight machine, weight checker, weight sorting machine, weighing machine, and etc,.

This dynamic capsule tablet check weigher adopts an innovative "unit expansion structure" and an "infinite parallel" working mode, which can infinitely improve the detection efficiency. Automatic capsule tablet checkweigher can weigh and inspect all capsules and tablets of different quantity levels, quickly eliminating unqualified products. The high-precision automatic capsule tablet check weigher can also be used for sampling, weighing and testing during the production process, making it possible to increase the sampling quantity (all modules are sampled at once) and sampling frequency, thereby better controlling the weight of drug particles. For further information about our services, or if you would like one of our professionals to contact you, please do not hesitate to contact us.

Automatic capsule tablet checkweigher photos

1. The core part of the equipment adopts high-precision electromagnetic balance weighing sensors, DSP high-speed signal processing systems, and military aviation level software algorithms, with fast measurement data, stable operation, and strong resistance to environmental interference;

2. Automatic capsule tablet checkweigher can detect all types of capsules such as 000 000 0 1 2 3 4 5 SA and SB, as well as conventional tablets;

3. The "unit expansion structure" and "infinite parallel" working mode of the entire machine allow a host to control up to 1024 single machines at the same time, which can infinitely improve work efficiency. At the same time, selecting models based on work efficiency becomes extremely convenient;

4. The mold adopts a building block overlapping and positioning structure. When changing the capsule model, the mold can be quickly disassembled and positioned with bare hands, ensuring accurate positioning;

5. The molds of adjacent capsule models are universal, such as 00 # and 0 #, 1 # and 2 #, 3 # and 4 #, to reduce the number of molds and reduce equipment usage costs;

6. Small size, space saving, and easy to move;

7. Reasonable design, minimal equipment failure points, convenient use, simple operation and maintenance, and low maintenance costs in the later stage;

8. Flexible work, can be connected to production equipment for use, or can be used offline on a single machine;

9. Production formula management call, rich data statistics, data storage, query, and printing functions;

10. Set a qualified range and quickly and automatically sort good and bad products;

11. Ergonomic design, large-sized color touch screen, user-friendly operation interface, and intuitive chart display;

12. The human-machine interface synchronously displays the weight value of each channel, and visually displays the qualification of the current channel product in the form of a green and red histogram. The device synchronously lights up the indicator light, making the detection process more intuitive;

13. The innovative design of three channels for good products, defective products, and unchecked products solves the problem of discharge of unchecked products during abnormal shutdowns and misjudgment;

14. Equipment failure automatic alarm, prompt alarm information;

15. Comply with 21CFR Part 11, Level 3 password, electronic record electronic signature, ensure data integrity, and facilitate audit tracking;

16. Rich peripheral interfaces, Ethernet, USB, COM ports, wireless WiFi, convenient for remote monitoring and networked data exchange.

Production: Up to 150000 capsules/hour

Capsule size: 000-5, slender, DB

Accuracy:+/-2 mg (+/-1 mg)

Inspection range: 20-20000 mg

Customization Philosophy:

The product demonstrating may not perfectly meet your requirements,

our philosophy is to customize your real need.

To minimizing idle capacity and function. To supply you performance and cost balanced products. Following are the factors shall be taken into account during customization:

1,Products to be packed

2,Container to be filled, type and specification.

3,Capacity requirement

4,Automation requirement

5,Protection requirement

6,Other specific requirement

The dynamic capsule tablet check weigher has grown into a weight part of production operation and management. Its functions not only include online weighing detection, but also help production users optimize the entire production process:

1.100% online testing of each product to avoid penalties caused by poor quality

2. Feedback parameters can be provided to front-end packaging equipment through weighing and testing

3. Can optimize and improve production processes, provide equipment operation efficiency, and save production materials

4. Reduce manual missed inspections, false inspections, and quality rework, and maintain product and brand reputation

5. Save labor, improve quality inspection rate, and comprehensively improve product quality

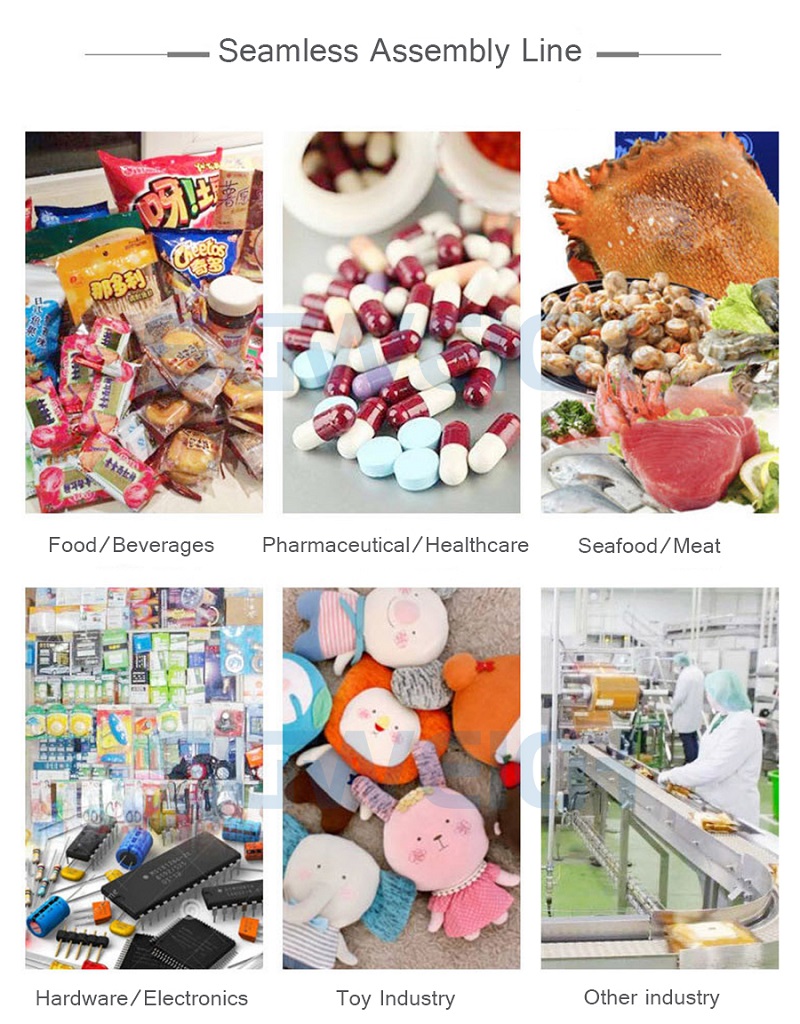

Shanghai Shigan Industrial Co., Ltd. is a manufacturer of weighing scales and metal testing machines that integrates research and development, design, production, and sales. Located in Shanghai, China, a developed region in the mechanical industry, we adhere to the principles of "excellent service and good quality". The company has complete equipment and independently produces various types of mechanical transmissions and hardware accessories. Brave in researching and innovating technologies, continuously improving, and receiving unanimous praise from a large number of enterprises. Shanghai Shigan has always been committed to the research and development and manufacturing of a series of assembly line packaging and testing equipment such as auto packing machine, multihead weigher packing machine system, multihead weigher, linear scale, check weigher, metal detector, and etc., bringing products that balance performance and price to every corner of the world.

Packaging:

1: Lubrication drive device

2: Divide the machine into modules

3: Wrap the module in plastic film

4: Package the module in a cardboard box

5: Making shipping marks

If there are any special requirements, we will package according to your requirements.

Delivery time:

All of our machines are customized, as different customers have different requirements. Dynamic capsule tablet check weighers will be delivered within 20 days, while large machines require longer delivery times.

On sale services:

1. Before mass production, send the machine drawings to the customer for approval.

2. Track every production process to ensure timely delivery.

3. Send machine inspection videos for customer approval before shipment.

4. Collaborate with freight forwarders to ship and keep customers informed of the latest developments in ETD and ETA.

After sales service:

5. Our customers can obtain manuals/videos for machine installation, adjustment, setup, and maintenance.

Online after-sales service:

6. If the machine malfunctions, we will respond within 4 hours and provide solutions through WhatsApp, WeChat, and Facebook within 24 hours.

Related Products

Automatic Sachet Packing Machine For Granules and Powder

Cashew Nuts Food Multihead Weigher Packaging Machine

Assembly Line Freeze-dried Fruit Food Metal Detector

Semi Automatic Particle Granule Weighing Filling Machine

Small Size Pouch Multi-lane Check Weigher Machine

20 grams Block Pepper Powder Auto Packing Machine

Hot Labels: health medicine,capsule check weigher,counting,check weigher machine,high efficiency,dynamic checkweigher,sugar coated tablets,supply,factory,price